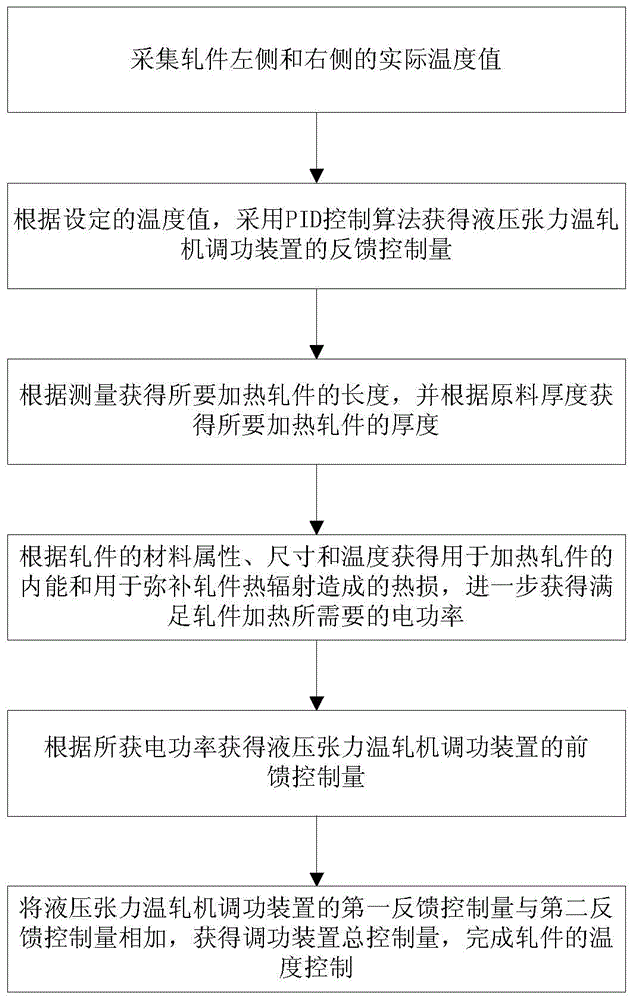

A temperature control method for metal rolled pieces in a hydraulic tension warm rolling mill

A temperature control method and hydraulic tension technology, applied in the direction of temperature control, metal rolling, etc., can solve the problems of inability to heat, which is not conducive to ensuring the uniformity of the temperature of the metal sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] An embodiment of the present invention will be further described below with reference to the accompanying drawings.

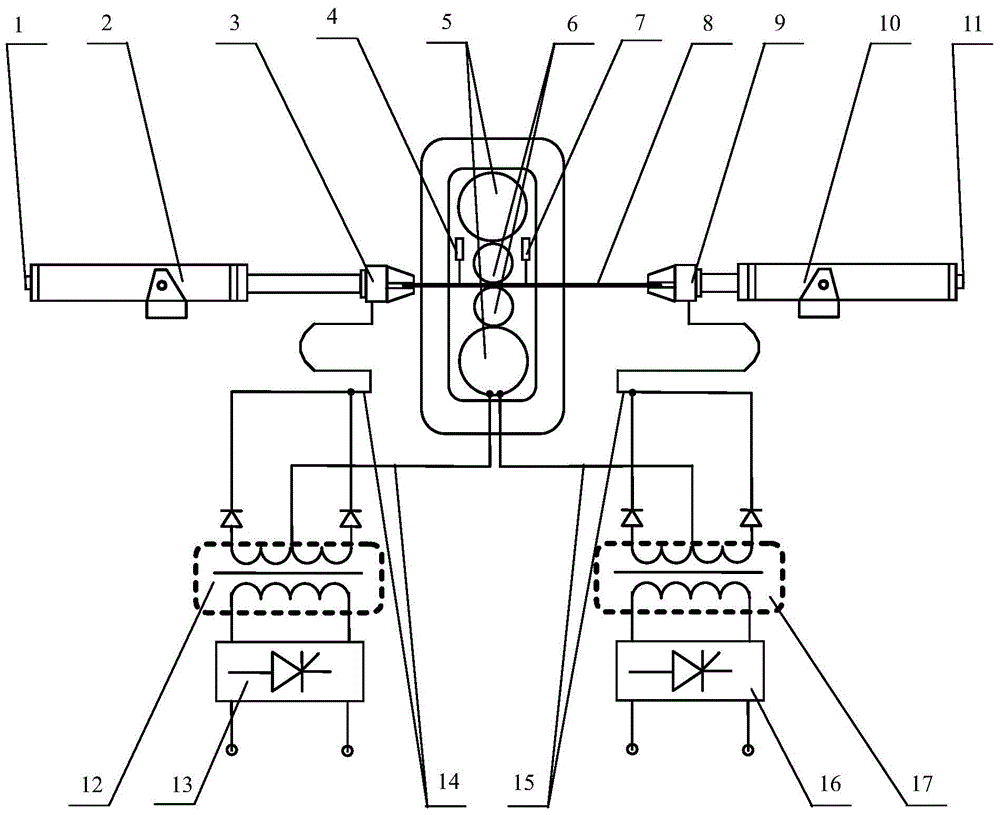

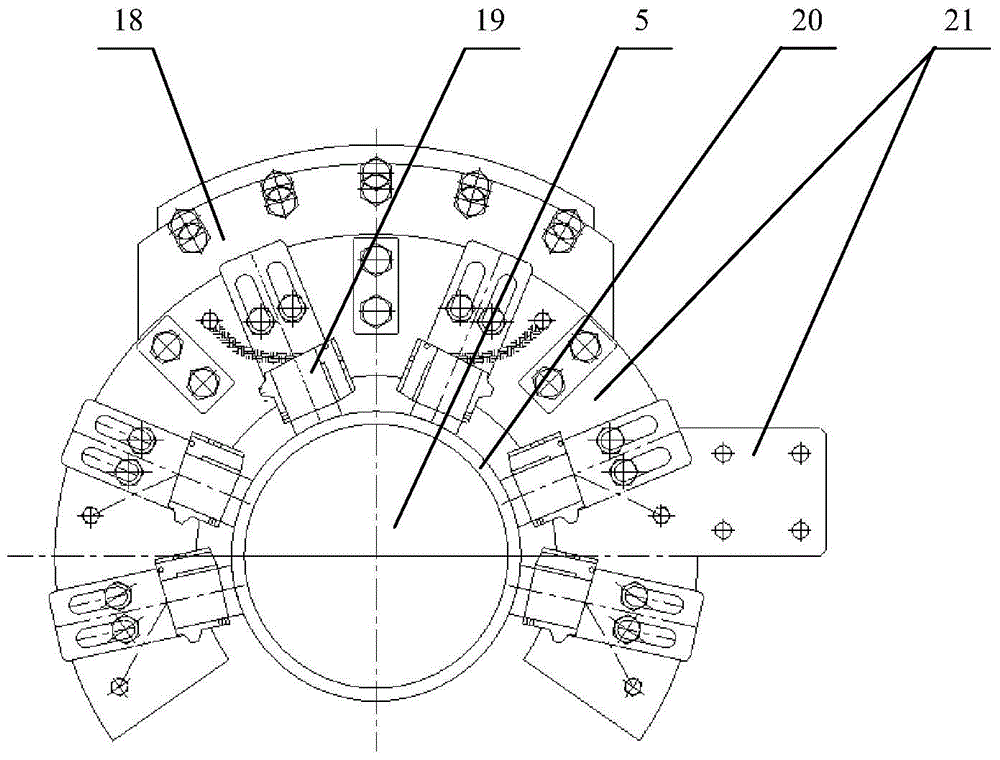

[0041] In this embodiment of the present invention, as figure 1 and figure 2 As shown in the figure, the hydraulic tension warm rolling mill mainly includes: the warm rolling mill body, which is mainly composed of rolling mill arch, support roll 5, work roll 6, pressing hydraulic cylinder, main motor, transmission shaft, etc.; left tension hydraulic pressure is arranged on the left and right sides of the rolling mill. Cylinder 2 and right tension hydraulic cylinder 10, left displacement sensor 1 is installed in left tension hydraulic cylinder 2, right displacement sensor 11 is installed in right tension hydraulic cylinder 10, and the displacement sensor is used to measure the length of the effective deformation area of rolling stock 8 during the rolling process and the running speed of the rolling piece; the left clamp 3 is connected with the left te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com