Cable trough combination for rail transit system

A rail transit and cable trough technology, applied in the mechanical field, can solve problems such as complex sealing and fitting structure, difficult heat dissipation and drainage, and inconvenient installation, and achieve good waterproof effect, enhanced heat dissipation and drainage effect, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

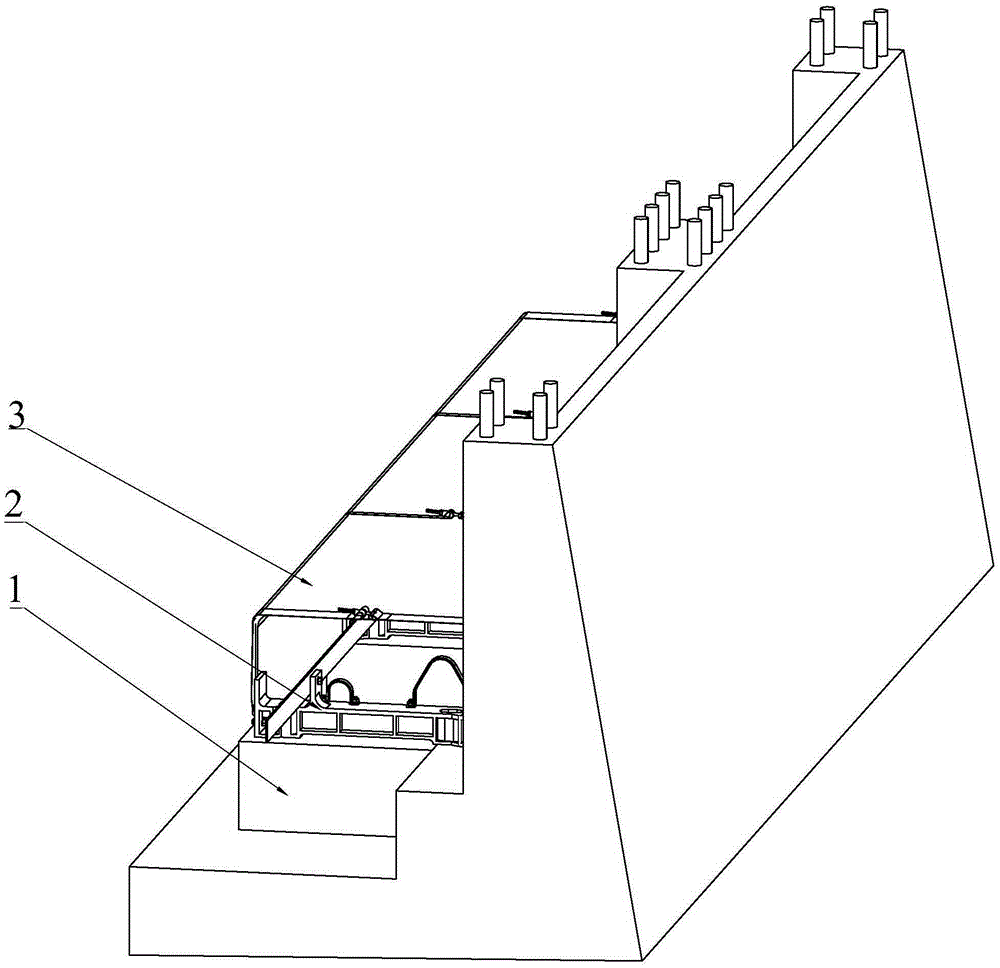

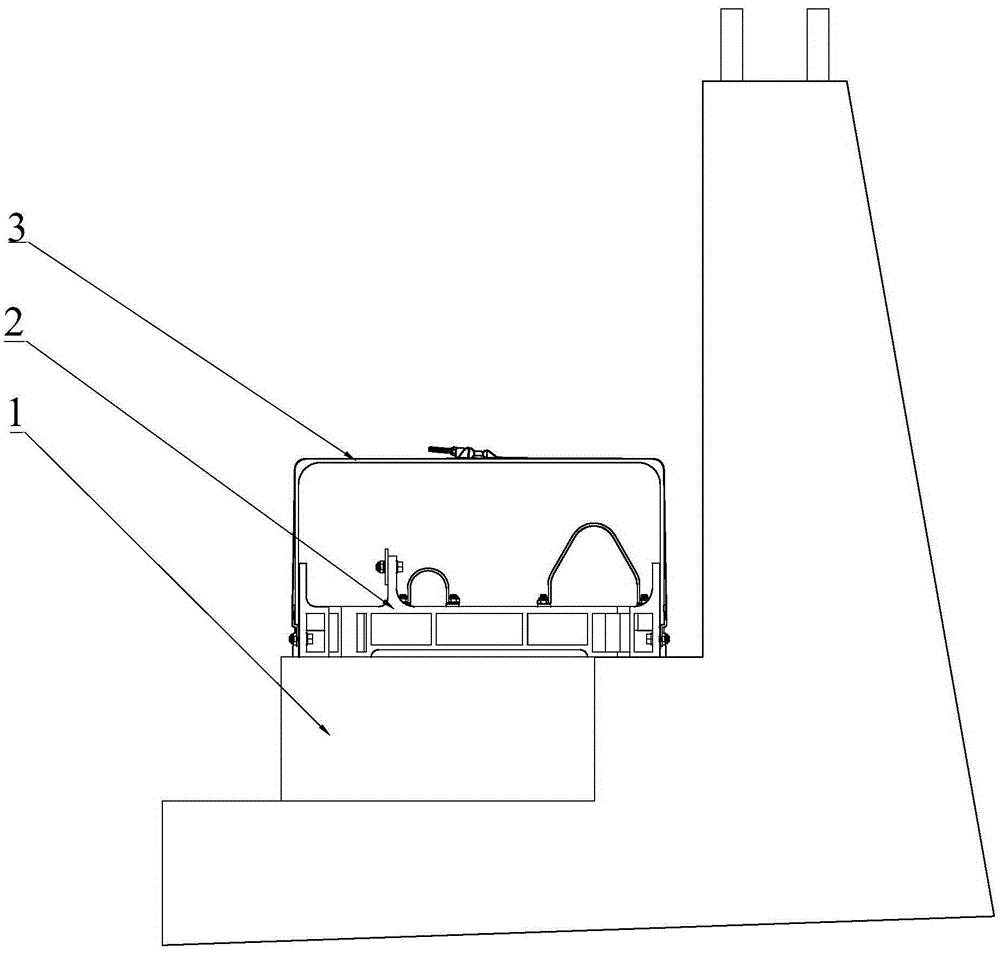

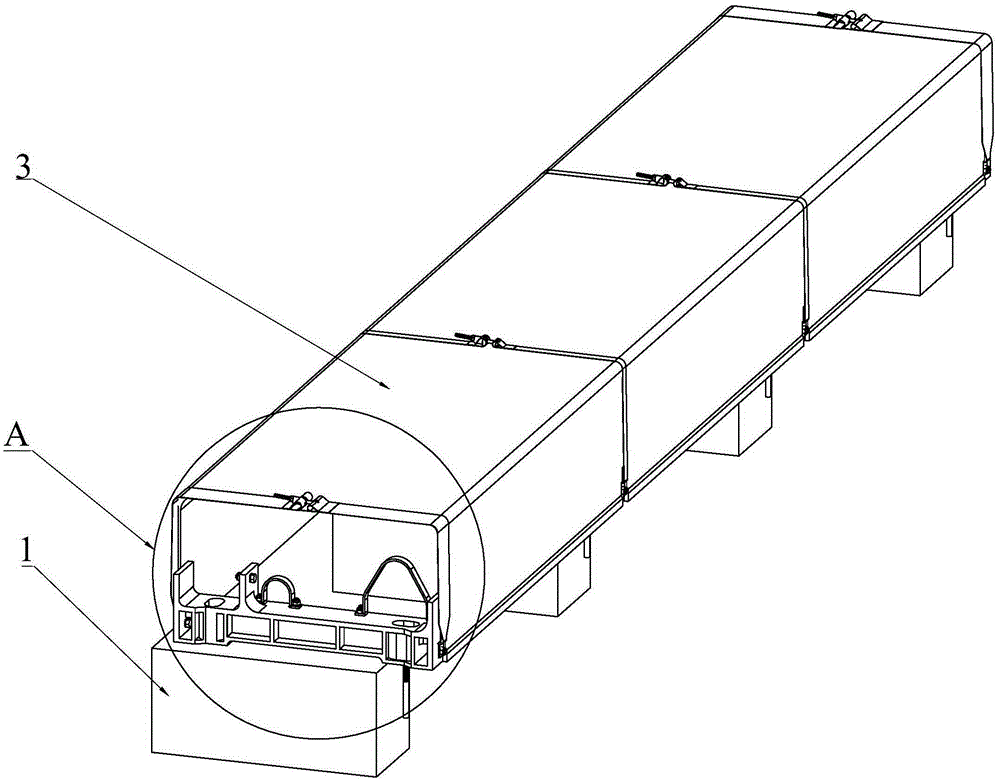

[0024] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the cable trough combination for rail transit system of the present invention includes several connected cable trough combination monomers, and the cable trough combination monomer includes several support blocks 1 arranged at intervals, fixedly connected on the top of the support block 1 The cable groove support 2 for supporting cables, the top of the support block 1 supports an inverted U-shaped cable groove cover 3 with openings at both ends, and the cable groove support 2 is located in the cable groove cover 3 and is connected with the The cable groove cover 3 is connected by first setting the support block 1, then fixing the cable groove bracket 2 on the support block 1, and finally fastening the inverted U-shaped cable groove cover 3 on the cable groove bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com