Water purifier with flipping cover device

A technology of water purifier and flip cover, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the difficulty of popularizing water purifiers and the difficulty of wider popularization of water purifiers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

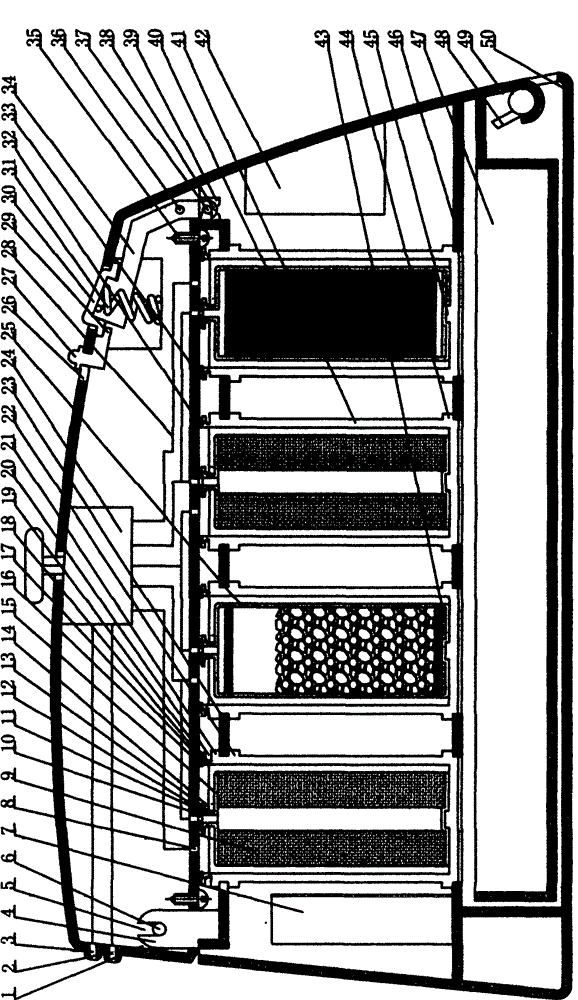

[0046] Example 1. The machine base 50 is provided with four filter cartridges, arranged in the word "one"; placed in each filter cartridge with two nozzle inner tanks, connected in series through the docking nozzles 8 of the integral warehouse cover 1 and the built-in pipeline 28, the front and rear ends They are respectively connected to the water inlet and outlet ports 2 and 3 located on the integral cover. The four inner tanks connected in series are the PP ring cylindrical solid fiber filter material layer end cover inner tank that enters water from the circumferential surface, the granular activated carbon sealed inner tank that enters water from the water inlet 43 at the lower end of the circumferential surface of the shell, and the second PP ring cylindrical solid fiber filter material layer end cover type liner, ultrafiltration membrane sealing filter liner at the water outlet hole 40 on the circumferential surface of the closed shell.

[0047] The rear end of the int...

Embodiment 2

[0077] Example 2. Embodiment 2 is the best implementation mode of the present invention.

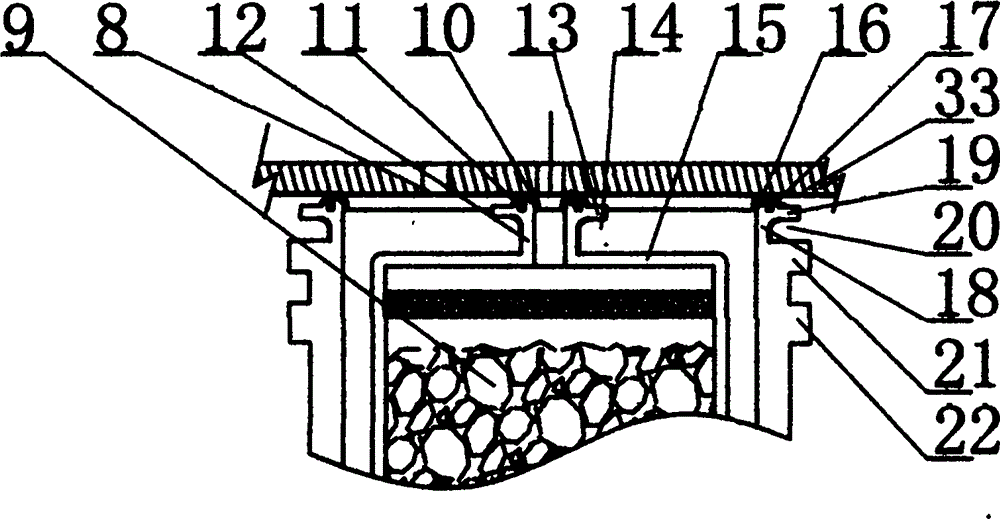

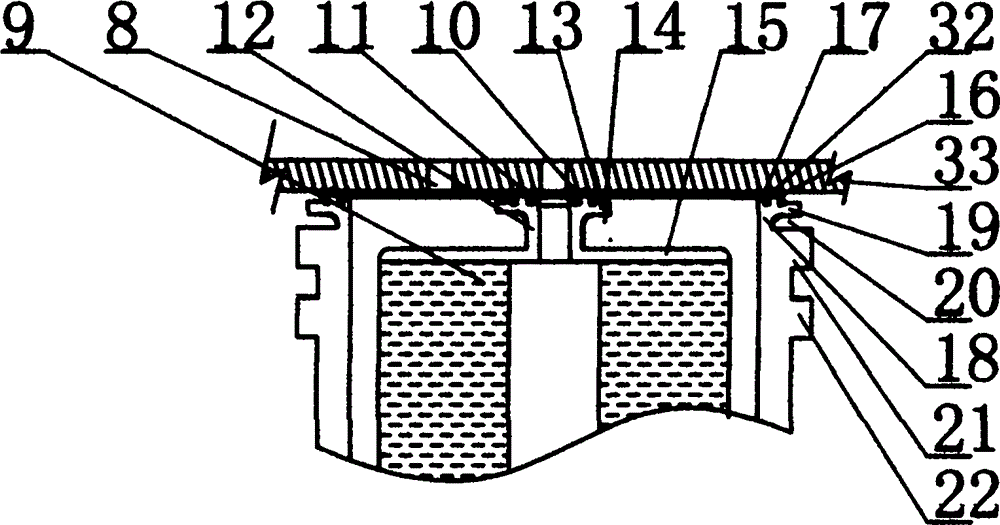

[0078] On the basis of Example 1, the machine base adopts a double-row filter cartridge structure, and the six filter cartridges in the first three rows are set as detachable filter cartridges. The detachable filter cartridge adopts the upper support mode to connect and cooperate with the machine base to form a whole: the upper and lower radial bosses 21 and 22 are arranged on the circumferential surface of the detachable filter cartridge, and the lower radial boss 22 passes through the machine base A notch is provided on the inner convex snap ring 23, and the upper and lower radial bosses 21, 22 are rotatably fitted with the snap ring 23 and axially limited. The lower end face of the snap ring is provided with a downward plug, and at a place separated from it by a position of the lower radial boss, two slope bosses slightly protruding downward are used for the exit limit of the lower r...

Embodiment 3

[0104] Example 3. On the basis of Examples 1 and 2, the inner bladder placed in the filter cartridge is replaced by a closed filter gall with a closed shell. The two external water ports located on the upper end surface of the closed filter gall are either concentrically arranged inside and outside, or arranged symmetrically, or arranged at the center of the circle and the eccentric place respectively.

[0105] Similar to the connection structure between the detachable filter cartridge and the machine base, the shell of the closed filter gall is either screwed with the slot of the machine base, or screwed with the machine base, or directly connected with the machine base, and connected with the machine base. Seat lock position; wherein, when the filter gall is connected and matched with the card slot of the machine base, or the connection and cooperation mode of the circumferential surface of the shell is adopted: the machine base is provided with an inner convex snap ring and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com