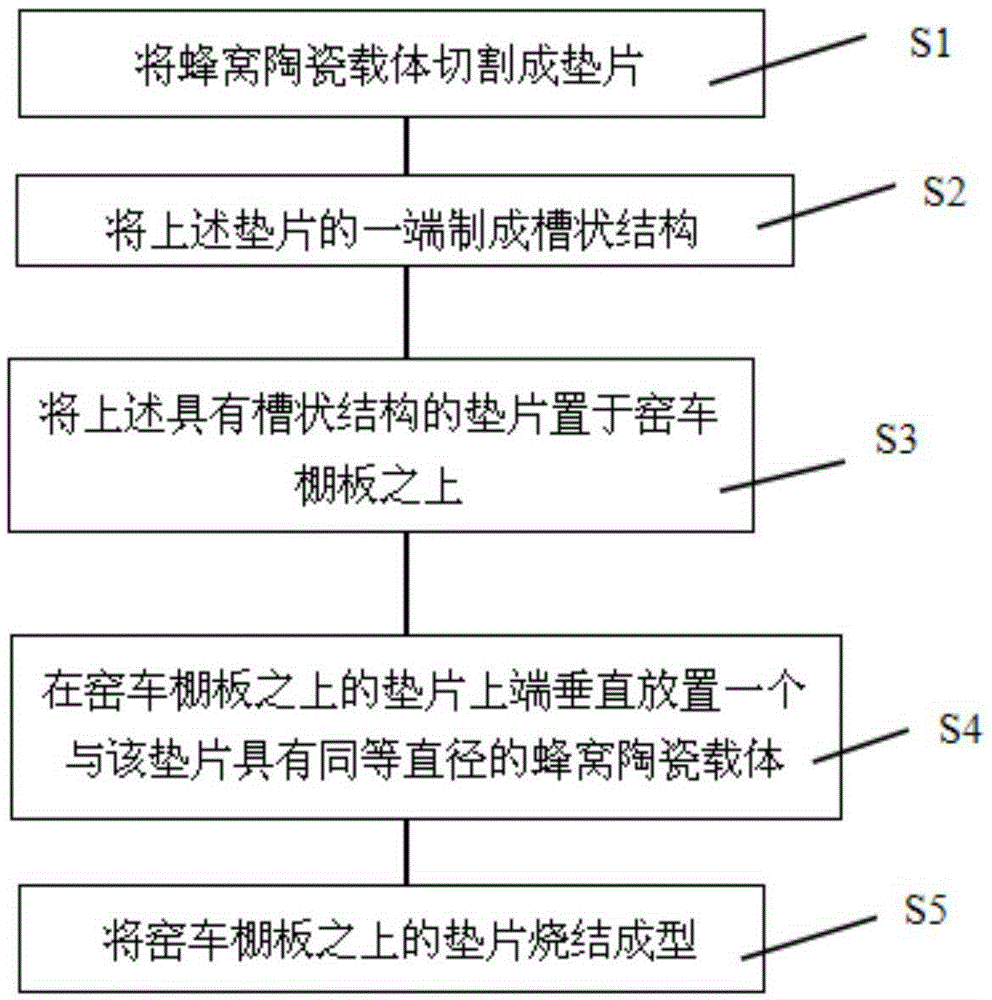

Manufacturing method for honeycomb ceramic carrier seat cushion

A technology of honeycomb ceramic carrier and production method, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of low firing pass rate, achieve the effects of increasing pass rate, reducing finished products, and simplifying kiln installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 is comparative example:

[0032] Cut the green blank into a gasket with a thickness of 25mm along the direction perpendicular to the channel; place the gasket on the kiln car shed plate, and place several strip gaskets evenly under each gasket; each seat cushion Place a biscuit product of the same diameter vertically on the top, fire it according to the existing firing system, and calculate the firing pass rate of the product.

Embodiment 2

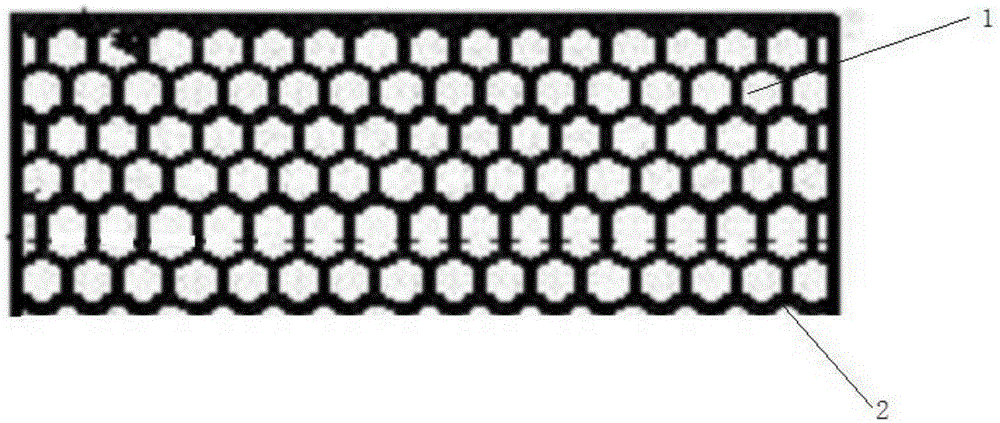

[0034] Cut the blank into a gasket with a thickness of 5mm along the direction perpendicular to the channel, and use a metal saw blade to draw a cross-shaped groove with a width of 2.2mm, a depth of 1.0mm, and an included angle of 30° on one end of the gasket Like structure, get a cushion. Put the end of the seat cushion with the groove-like structure facing down on the kiln car shed; place a green product of the same diameter vertically on each seat cushion, and fire according to the existing firing system to calculate the firing rate of the product. pass rate.

Embodiment 3

[0036] Cut the blank into a gasket with a thickness of 15mm along the direction perpendicular to the channel, and use a metal saw blade to draw a cross-shaped groove with a width of 4.4mm, a depth of 1.5mm, and an included angle of 45° on one end of the gasket Like structure, get a cushion. Put the end of the seat cushion with the groove-like structure facing down on the kiln car shed; place a green product of the same diameter vertically on each seat cushion, and fire according to the existing firing system to calculate the firing rate of the product. pass rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com