A Smelting Reduction Ironmaking Method Partially Substituting Pure Oxygen

A pure oxygen, melter gasifier technology, applied in furnace types, furnaces, shaft furnaces, etc., can solve the problems of easy bonding of shaft furnaces, large coke usage, gas back-channeling, etc., to reduce the cost of pure oxygen consumption, The effect of improving the reduction metallization rate and reducing the CO2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

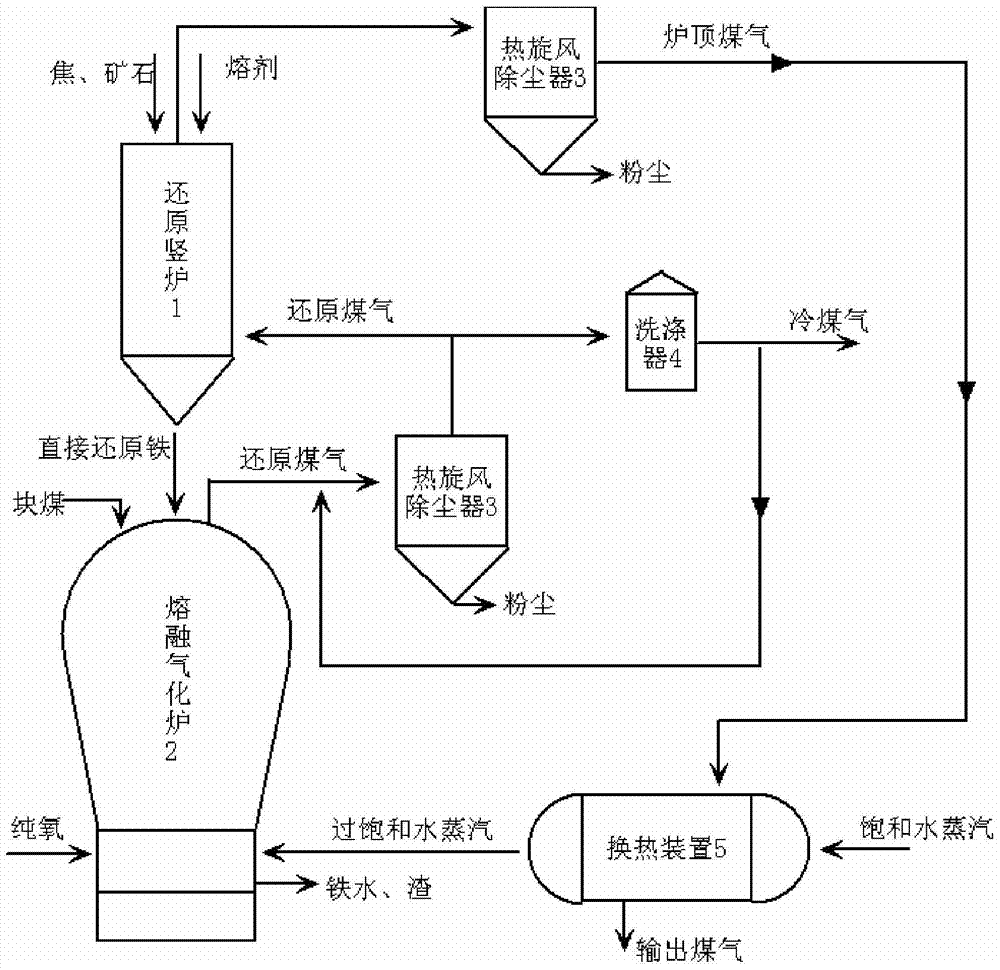

[0024] see figure 1 , the smelting reduction ironmaking method that partially replaces pure oxygen in the present invention, it passes the furnace top gas with a temperature of 250°C from the reduction shaft furnace 1 into the hot cyclone dust collector 3, and enters the heat exchange device 5 after being dedusted by the hot cyclone During heat exchange with 0.2MPa saturated steam, the saturated steam after the heat exchange becomes supersaturated steam at a temperature of 150°C, and the supersaturated steam is injected into the melter-gasifier 2 from the tuyere with an injection volume of 20Nm 3 / tHM, while injecting pure oxygen into other tuyeres, the amount of pure oxygen is 530Nm 3 / tHM. See Table 1 for the content of each component in the reduced gas coming out of the melter-gasifier 2 after the reaction in the melter-gasifier 2 . The reduced gas produced in the melter-gasifier 2 is mixed with cold gas and then enters the hot cyclone dust collector 3. The gas is divided...

Embodiment 2

[0026] The furnace top gas with a temperature of 280°C from the reduction shaft furnace 1 is passed into the hot cyclone dust collector 3, and after being dedusted by the hot cyclone, it enters the heat exchange device 5, and exchanges heat with 0.22MPa saturated steam. Saturated steam becomes supersaturated steam at a temperature of 170°C, and the supersaturated steam is sprayed into the melter-gasifier 2 from the tuyere with an injection volume of 30Nm 3 / tHM, while injecting pure oxygen into other tuyeres, the amount of pure oxygen is 520Nm 3 / tHM. See Table 1 for the content of each component in the reduced gas coming out of the melter-gasifier 2 after the reaction in the melter-gasifier 2 . The reduced gas produced in the melter gasifier 2 is mixed with cold gas and then enters the hot cyclone dust collector 3. The gas is divided into two paths, one path enters the reduction shaft furnace 1 at a temperature of 820°C, and the other path enters the scrubber 4 after washing...

Embodiment 3

[0028] The furnace top gas with a temperature of 300°C from the reduction shaft furnace 1 is passed into the hot cyclone dust collector 3, and after being dedusted by the hot cyclone, it enters the heat exchange device 5, and exchanges heat with 0.25MPa saturated steam. The saturated steam becomes supersaturated steam, the temperature is 180°C, and the supersaturated steam is sprayed into the melting and gasification furnace 2 from the tuyere, and the injection volume is 40Nm 3 / tHM, while injecting pure oxygen into other tuyeres, the amount of pure oxygen is 500Nm 3 / tHM. See Table 1 for the content of each component in the reduced coal gas coming out of the melter-gasifier 1 after the reaction in the melter-gasifier 1 . The reduced gas produced in the melter-gasifier 1 is mixed with cold gas and then enters the hot cyclone dust collector 3. The gas is divided into two paths, one path enters the reduction shaft furnace 1 at a temperature of 830°C, and the other path enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com