Positioning locking device for steel discharging machine

A locking device and tapping machine technology, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of insufficient thrust, inaccurate discharge position, affecting production work, etc., to improve work efficiency, ensure positioning and locking, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

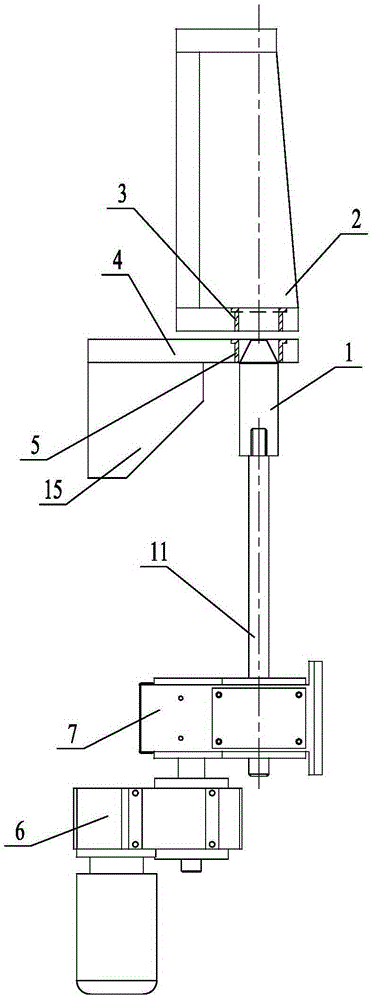

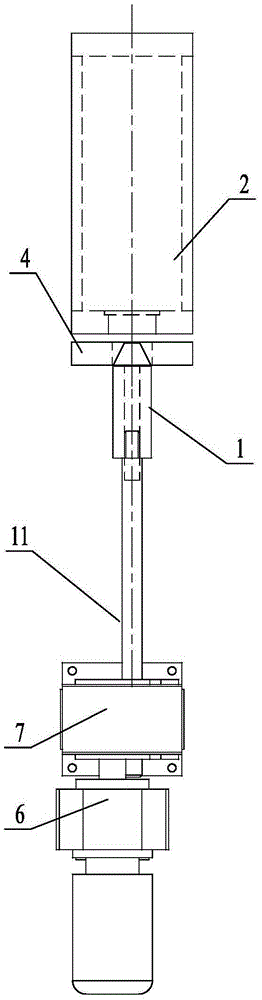

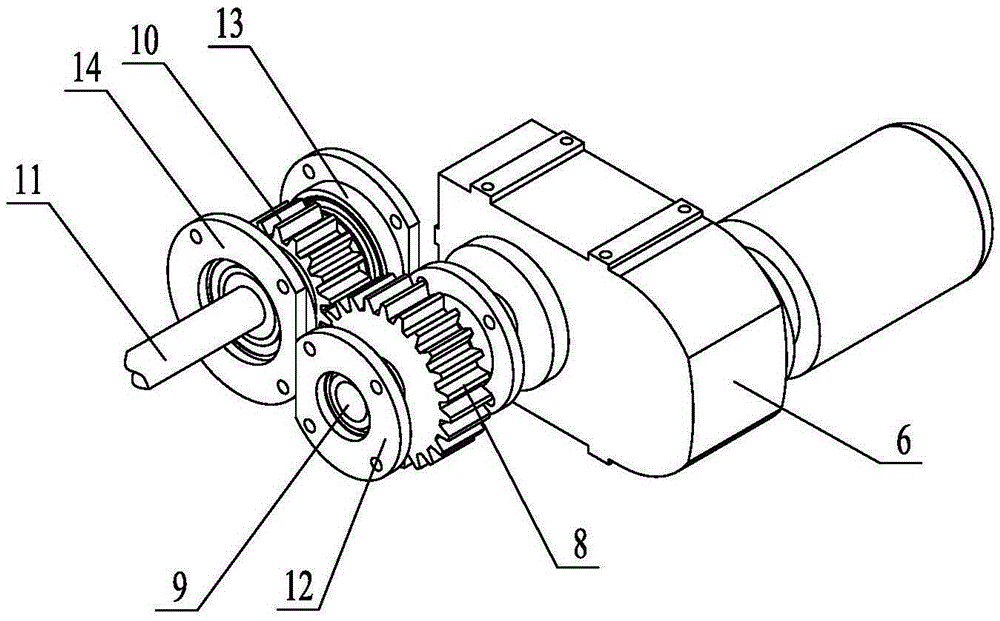

[0013] As shown in the figure; the positioning and locking device for the tapping machine in the embodiment mainly consists of a stop pin 1, an upper positioning seat 2, an upper positioning sleeve 3, a lower positioning seat 4, a lower positioning sleeve 5, a motor reducer 6, a housing 7, Pinion 8, pinion shaft 9, pull rod nut gear 10, pull rod 11, small bearing cap 12, pull rod nut 13, pull rod bearing cap 14 and reinforcing plate 15 etc. are formed.

[0014] Such as figure 1 , figure 2 As shown, the upper positioning sleeve 3 is set in the upper positioning seat 2, the lower positioning sleeve 5 is set in the lower positioning seat 4, the stop pin 1 is connected with the telescopic drive mechanism, and the stop pin 1 can be driven by the telescopic drive mechanism. Move back and forth; when the stop pin 1 passes through the upper positioning slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com