A tensioning rod for a compact spinning device

A concentrated spinning, intermediate position technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of insufficiency of tension rods and high cost of imported tension rods, and achieve smooth operation and meet process requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

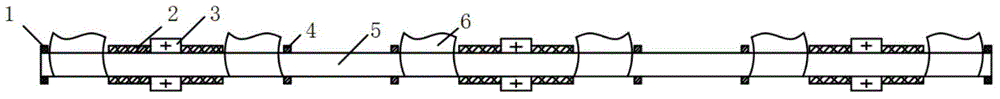

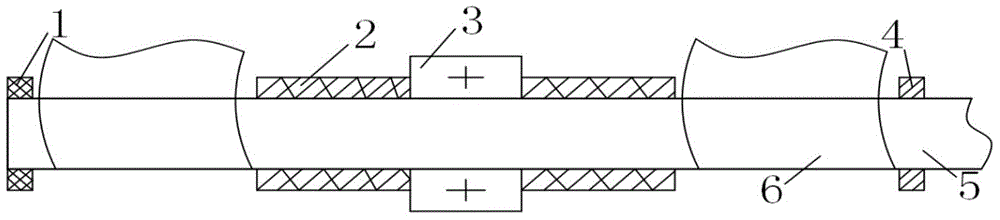

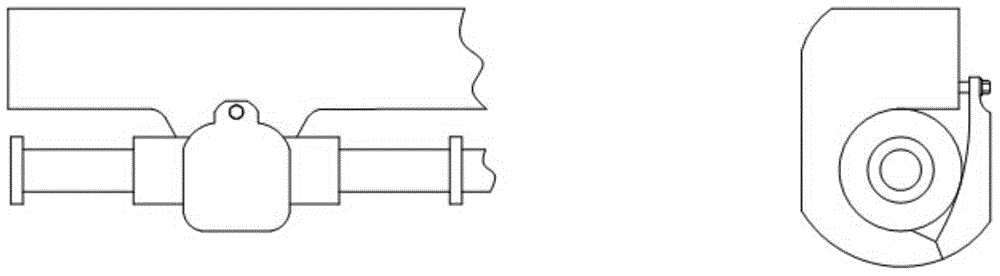

[0033] The tension rod used in the compact spinning device of this embodiment includes an intermediate steel shaft 5, at least one needle bearing 3 is sleeved on the outer circumference of the intermediate steel shaft 5, and the two sides of the needle bearing 3 are installed There is a positioning sleeve 2 sleeved on the outer circumference of the intermediate steel shaft 5, and a spacer is sleeved on the intermediate steel shaft 5, and an installation space for assembling the grid ring 6 is formed between the spacer and the positioning sleeve 2 .

Embodiment 2

[0035]The tension rod used in the compact spinning device of this embodiment includes an intermediate steel shaft 5, at least one needle bearing 3 is sleeved on the outer circumference of the intermediate steel shaft 5, and the two sides of the needle bearing 3 are installed There is a positioning sleeve 2 sleeved on the outer circumference of the intermediate steel shaft 5, and a spacer is sleeved on the intermediate steel shaft 5, and an installation space for assembling the grid ring 6 is formed between the spacer and the positioning sleeve 2 The spacer includes a steel spacer 1 and a plastic spacer 4, the two ends of the middle steel shaft 5 are installed with a steel spacer 1, and the spacers at the remaining positions of the middle steel shaft 5 are plastic spacers 4.

Embodiment 3

[0037] The tension rod used in the compact spinning device of this embodiment includes an intermediate steel shaft 5, at least one needle bearing 3 is sleeved on the outer circumference of the intermediate steel shaft 5, and the two sides of the needle bearing 3 are installed There is a positioning sleeve 2 sleeved on the outer circumference of the intermediate steel shaft 5, and a spacer is sleeved on the intermediate steel shaft 5, and an installation space for assembling the grid ring 6 is formed between the spacer and the positioning sleeve 2 The spacer includes a steel spacer 1 and a plastic spacer 4, the two ends of the middle steel shaft 5 are installed with a steel spacer 1, and the spacers at the rest of the middle steel shaft 5 are plastic spacers 4; Three needle roller bearings 3 are sheathed on the outer circumference of the middle steel shaft 5, and the three needle roller bearings 3 are the first needle roller bearing, the second needle roller bearing and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com