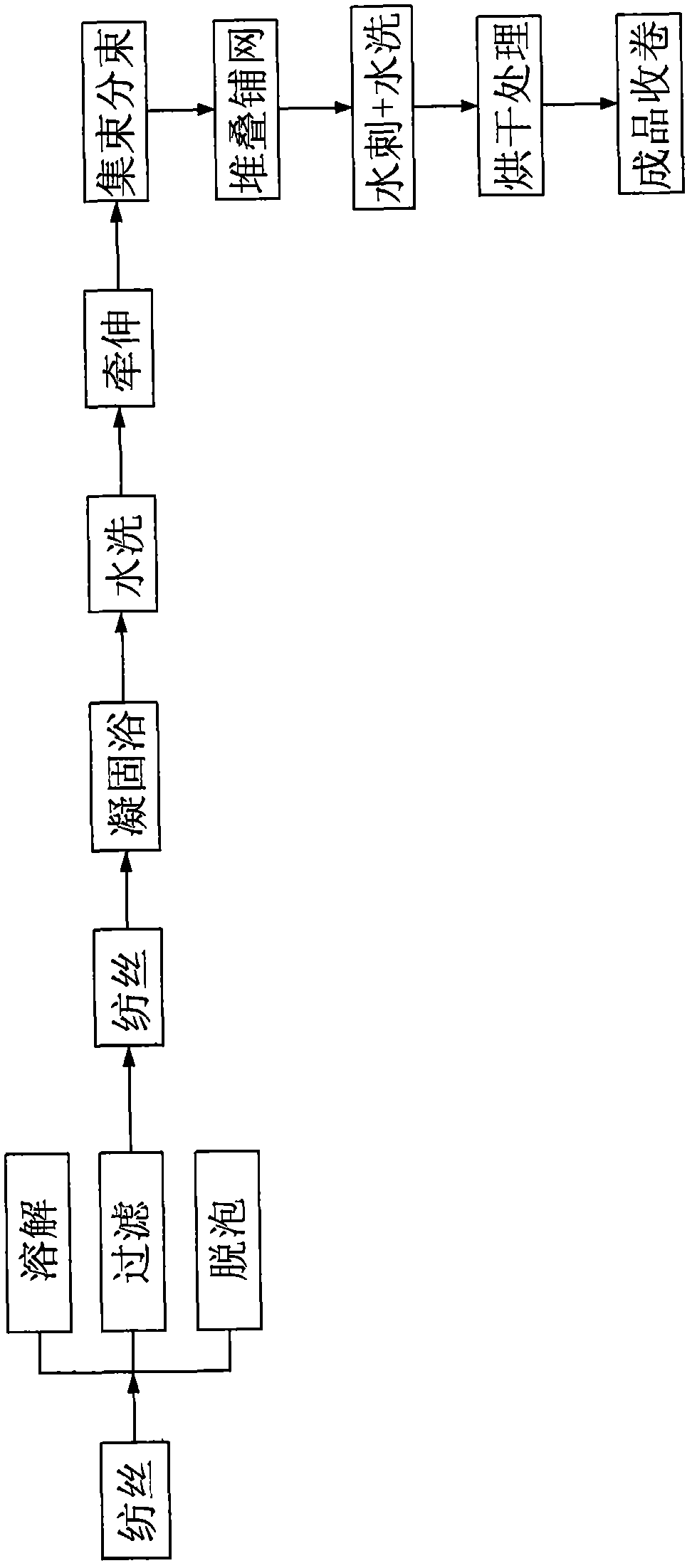

Process and equipment for preparing pure chitosan fiber filament non-woven fabric based on wet spinning technology

A technology of chitosan fiber and wet spinning, which is applied in the production of complete sets of equipment for artificial threads, wet spinning, fiber chemical characteristics, etc., can solve the problems of high cost and low strength, and achieve the goal of overcoming poor firmness and firmness. Good, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

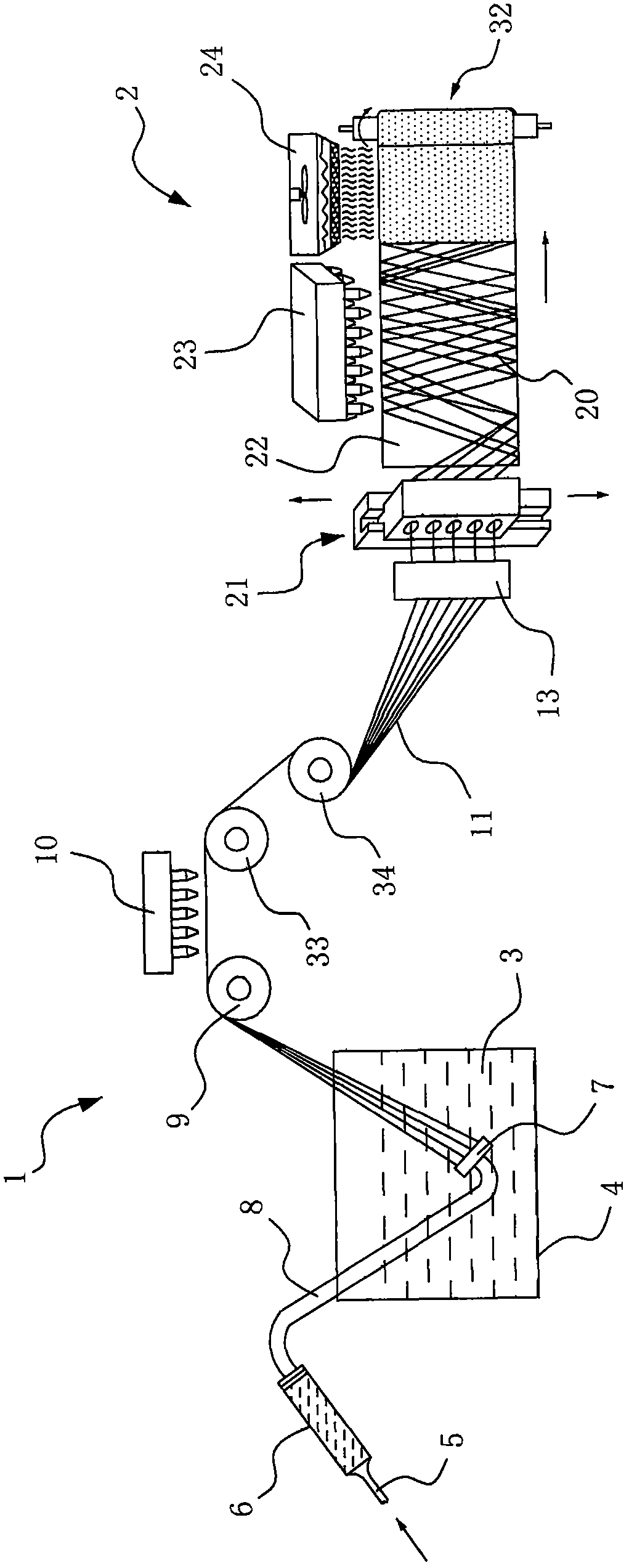

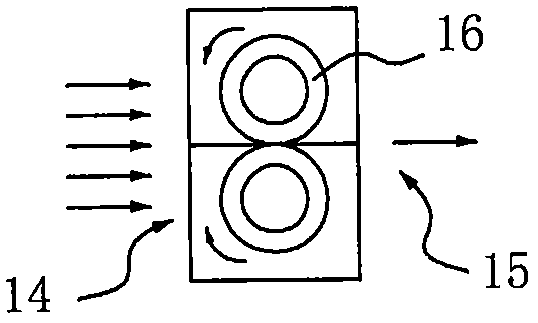

[0046] Such as figure 2 , 3 , 4, 5, and 6, a kind of equipment for preparing pure chitosan fiber filament non-woven fabric based on wet spinning technology is composed of wet spinning device 1 and forming device 2, and the wet spinning The device 1 consists of a coagulation bath container 4 with a coagulation bath liquid 3, a filter 6 with a spinning stock solution inlet 5, the spinning stock solution enters the filter 6 through the spinning stock solution inlet 5, connects the filter 6 and extends into the coagulation bath The liquid inlet pipe 8 with the spinneret 7 in the container 4, the godet roll 9 and the washing device 10 for connecting the spinning place of the spinneret 7, and the washing device 10 can adopt ultrasonic cleaning or pure water spraying commonly used in the art. Rinse and clean, forming device 2 comprises a bunching and splitting device 13 for concentrating and dispersing chitosan fiber tow 11, and bunching and splitting device 13 includes a pair of o...

Embodiment 2

[0049] In order to meet the actual production needs, a winding mechanism 32 can be set at the output end of the web forming machine net curtain 22, and the filament fiber web 20 on the web forming machine net curtain 22 is dried by the drying mechanism 24, and then rolled up by the winding mechanism 32. Directly wound and packaged. Between the godet roll 9 and the bunching and splitting device 13, the drafting roll for improving the strength of the chitosan fiber tow 11 can also be selected, and the drafting roll consists of a main drafting roll 33 and a secondary drafting roll 34 composition.

Embodiment 3

[0051] The same parts of this embodiment and other embodiments will not be repeated, and the difference is that a second molding device is provided, such as Figure 7 As shown, the forming device includes a conveying roller 36 for spreading the wet fiber tow 35, and a conveying screen 37 connected to the conveying roller 36 for conveying the spread wet fiber tow 35. A drafting roller 38 for drafting the wet fiber tow 35 is arranged between the conveying roller 36 and the conveying mesh curtain 37 .

[0052] The output end 39 of conveying net curtain 37 is connected with a swing net curtain 41 that is used to reciprocally stack wet fiber tow 35 into wet fiber tow net 40, and the output end 42 of described swing net curtain 41 is provided with a The stacked wet fiber tow webs 40 intersect each other layer by layer with a web forming machine net curtain 43, and at least one side of the web forming machine web curtain 43 is provided with a hydroentanglement device for hydroentangl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap