Compound cooling ventilator with interior self-adaption cooling circulation

A cooling cycle, self-adaptive technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of easy generation of condensed water, uneven heating and cooling of motors, unfavorable motors, etc., to reduce noise, low noise, The effect of condensed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

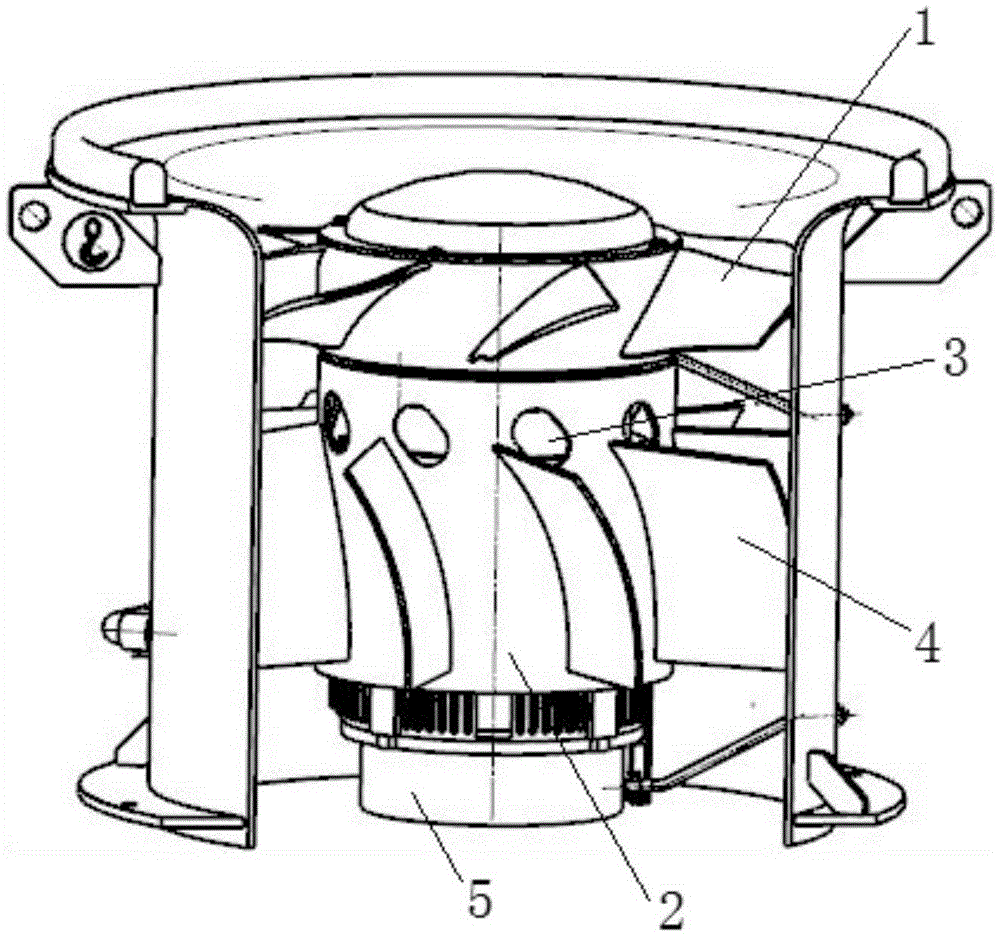

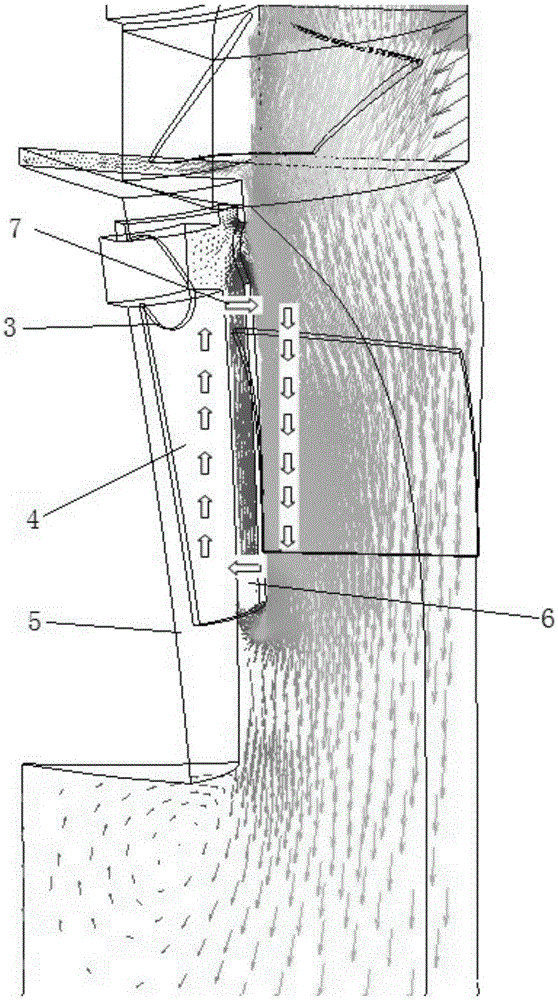

[0013] In the recooling ventilator with internal self-adaptive cooling cycle of the present invention, the front end of the motor 5 is equipped with an impeller 1, the motor 5 is covered with an inner air cylinder 2, and the inner air cylinder 2 is located behind the impeller 1 and maintains a gap. There is a rear guide vane 4, which is characterized in that: the front of the rear guide vane 4 on the inner air cylinder 2 is provided with a cooling ring, the cooling ring includes a group of cooling holes 3, and each rear guide vane 4 is provided with a cooling hole 3 in front, cooling The hole 3 is in the shape of a long hole, and its length direction is consistent with the inlet airflow angle of the rear guide vane 4 . Such as figure 1 As shown, in order to meet the requirements of the new generation of electric locomotives for the recooling fan with light weight, compact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com