Microporous high-expansion adhesive tape and preparation method thereof

A high-expansion, adhesive tape technology, applied in the field of automotive adhesive tape, can solve the problems of optimizing automobile NVH performance, low expansion ratio, and high expansion ratio, achieving good market application prospects, high production efficiency, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention also provides a preparation method of a microporous high-expansion adhesive tape, which is used to prepare the above-mentioned high-expansion adhesive tape. The raw materials are obtained according to the above-mentioned high-expansion adhesive tape formula, and an internal mixer, an open mill, and a single-screw extruder are used to prepare the method. The equipment composed of the machine includes the following steps:

[0026] Step 1) mixing the raw rubber, plasticizer and filler in an internal mixer at 110-120°C for 10-15 minutes for mastication, and then cooling down to room temperature to obtain the masticated rubber;

[0027] Step 2) Mixing the plasticized rubber obtained in the above step 1 with foaming agent, vulcanizing agent, vulcanization accelerator and vulcanization activator in an open mill at an environment of 60°C or less for 10 to 15 minutes to obtain a uniform mixed rubber ;

[0028] Step 3) Extrude the compound...

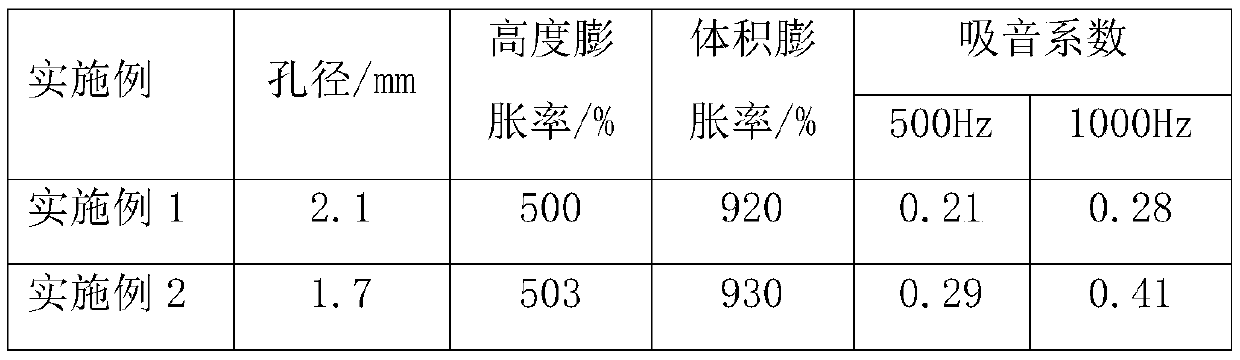

Embodiment 1

[0034] The present embodiment provides a kind of microporous high-expansion adhesive tape, and its preparation method comprises the following steps:

[0035] Step 1) mastication: in parts by weight, at first 40 parts of EPDM rubber, 40 parts of thermoplastic styrene-butadiene rubber, 10 parts of polyolefin thermoplastic elastomers and 60 parts of paraffin oil are added in the internal mixer, Mixed at 120°C for 10 minutes, visually inspected that the rubber and plastic blended into a homogeneous phase, then added 30 parts of calcium carbonate, mixed at 120°C for 5 minutes, the glue came out, passed through the two-roller open mill several times to accelerate cooling, and stood still to obtain plastic rubber;

[0036] Step 2) mixing: the plasticized rubber prepared in the above step 1, 1.2 parts of sulfur, 0.5 parts of 2-thiol phenylpropanthiazole, 2 parts of zinc dibutyldithiocarbamate, 2 parts of tetramethyl disulfide Add thiuram, 10 parts of azodicarbonamide, 3 parts of 4,4'...

Embodiment 2

[0040] The present embodiment provides a kind of microporous high-expansion adhesive tape, and its preparation method comprises the following steps:

[0041]Step 1) Mastication: In parts by weight, first add 40 parts of EPDM rubber, 10 parts of styrene-butadiene rubber, 40 parts of thermoplastic styrene-butadiene rubber, 10 parts of polyolefin thermoplastic elastomers and 60 parts of naphthenic oil Put it into the internal mixer, knead at 120°C for 10 minutes, visually observe that the rubber and plastic are blended into a homogeneous phase, then add 30 parts of calcium carbonate, knead at 120°C for 5 minutes, the glue comes out, and pass through the two-roller open mill several times to accelerate Lower the temperature and leave it to stand to obtain plasticized rubber;

[0042] Step 2) mixing: the plasticized rubber prepared in the above step 1, 1.2 parts of sulfur, 0.8 parts of 2-thiol phenylpropanthiazole, 2.2 parts of zinc dibutyldithiocarbamate, 2 parts of tetramethyl di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com