Stable shock absorber of automobile

A shock absorber, a stable technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of easy misalignment, wear and corrosion of the guiding mechanism, and achieve stable and rapid shock absorption and buffering, The effect of smooth and smooth damping in the direction of axis movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

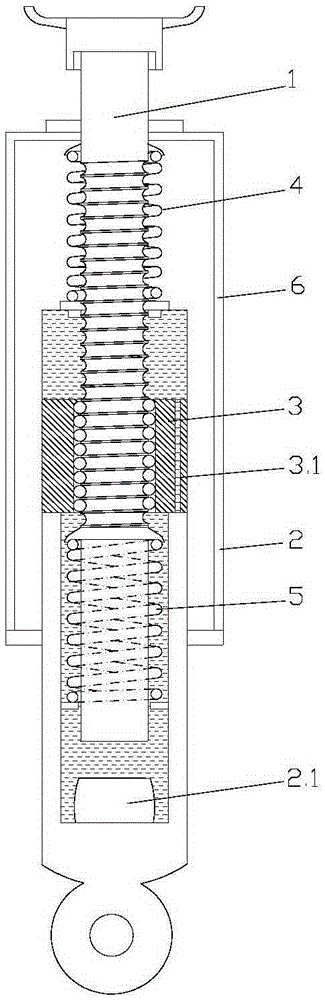

[0016] refer to figure 1 The automobile stable shock absorber shown includes a buffer rod 1 and a buffer sleeve 2 sheathed outside the bottom side of the buffer rod 1. The shaft of the buffer rod 1 is a screw structure, and the inside of the buffer sleeve 2 is provided with a Screw sleeve 3, screw sleeve 3 is provided with a thread groove, and there are several balls in the thread groove, the screw sleeve 3 accurately positions the buffer rod 1 in the radial direction, ensuring that the buffer rod 1 moves smoothly along its axial direction without skewing , the screw sleeve 3 is fixed on the upper side of the inner middle of the buffer sleeve 2, and the screw sleeve 3 separates the buffer sleeve 2 into two independent buffer chambers, the upper and lower, and the buffer chamber is filled with hydraulic oil. The cavity is used to balance the oil pressure of the balance channel 3.1, the matching accuracy of the screw sleeve 3 and the buffer sleeve 2 is easy to ensure, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com