Four-series non-dispersive infrared gas sensor

A non-spectral infrared and gas sensor technology, applied in the field of gas detection equipment, can solve problems such as development obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

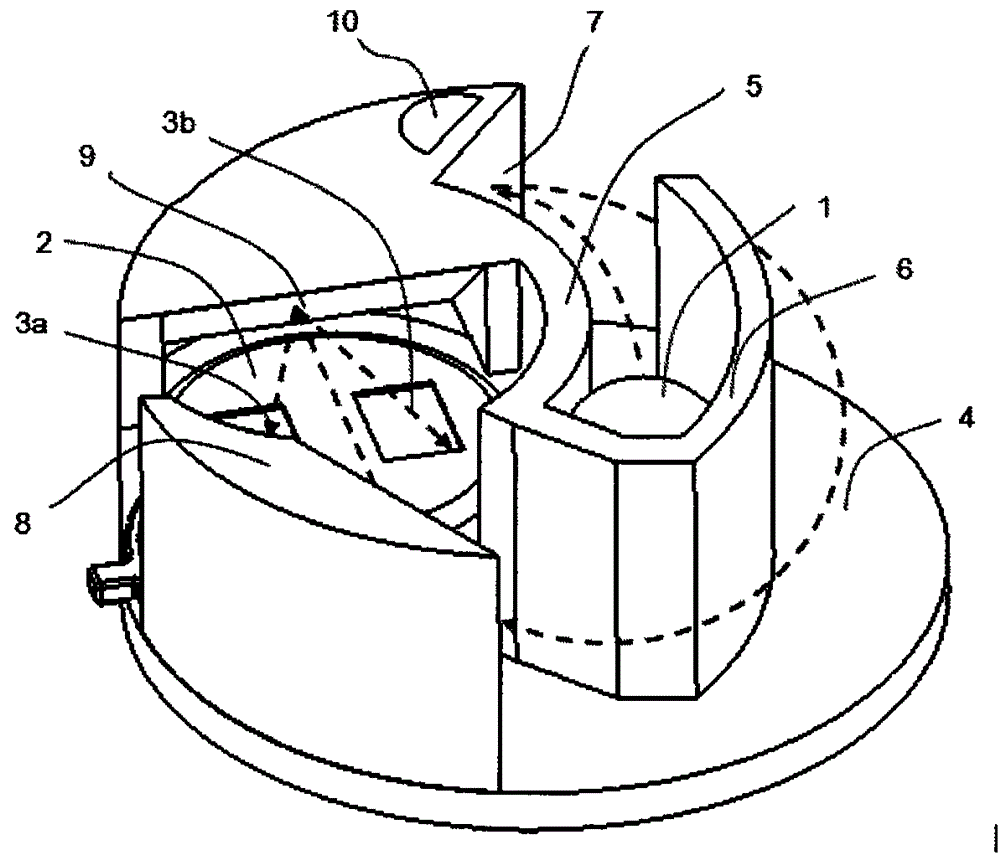

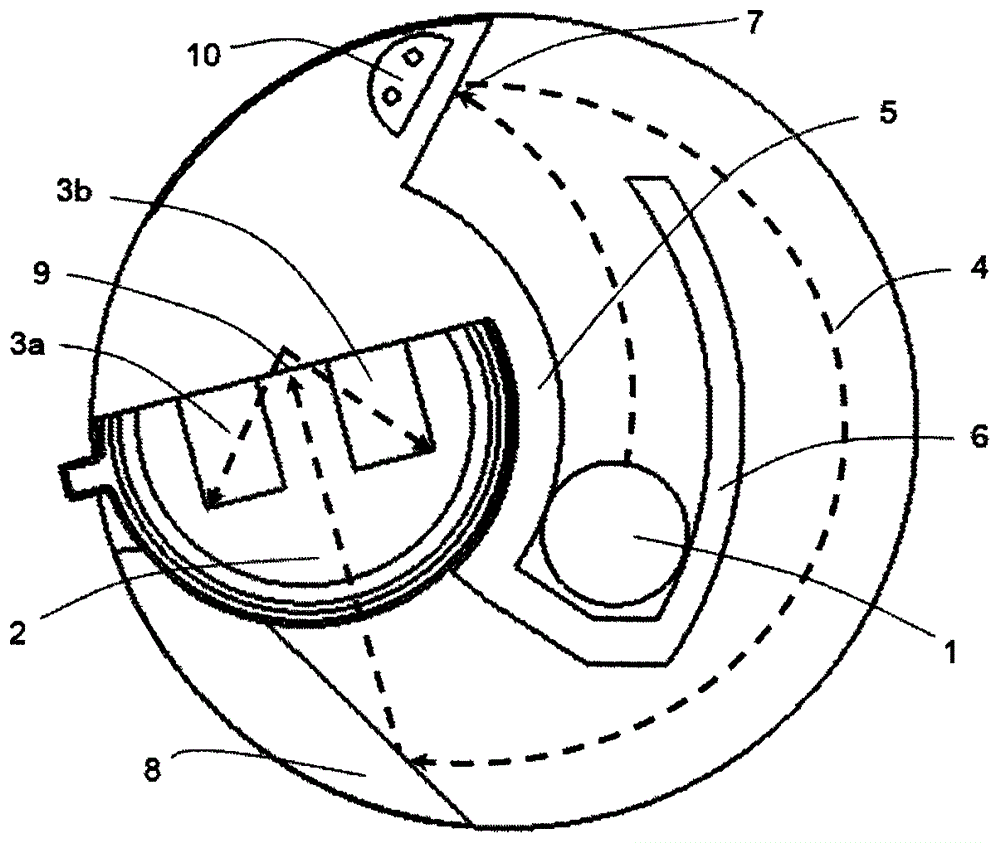

[0025] A specific embodiment of the present invention is described in detail as follows in conjunction with legend:

[0026] figure 1 Expresses the overall architecture of the invention.

[0027] In order to further improve the optical path length of the four-series non-spectral infrared (NDIR) gas sensor of the British Dynament company and the uniformity of distribution in the gas chamber, the invention provides a four-series non-dispersive infrared gas sensor.

[0028] In the narrow space of the four-series gas sensor, without changing the existing light source and package size of the detector element, an improved design of the optical path is provided. The extended optical path is more evenly distributed inside the sensor housing, further improving the output signal strength of the detector and enhancing The signal-to-noise ratio is beneficial to the subsequent signal conditioning and improves the sensitivity of the sensor. Moreover, a temperature and humidity sensor is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com