Photonasty resin composition

A technology of photosensitive resin and composition, applied in optics, optomechanical equipment, instruments, etc., can solve problems such as inability to exert durability, reduced pattern durability, and reduced reactivity, and achieve excellent chemical resistance and high durability , the effect of excellent reactivity

Active Publication Date: 2016-02-10

DONGWOO FINE CHEM CO LTD

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Therefore, the curing condition of the photosensitive resin composition is no longer the conventional high-temperature curing, but requires the necessity of low-temperature curing, but the low-temperature curing has the problems of reduced reactivity and reduced durability of the formed pa

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

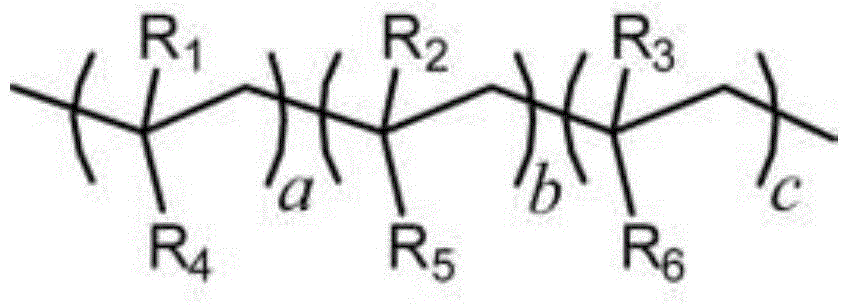

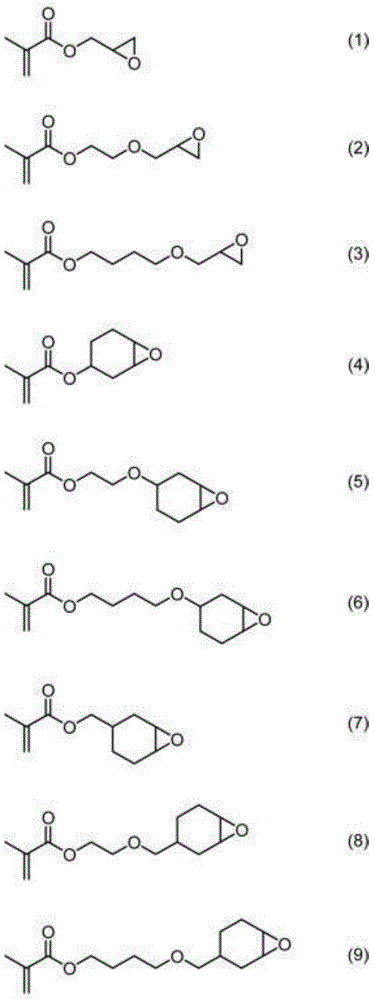

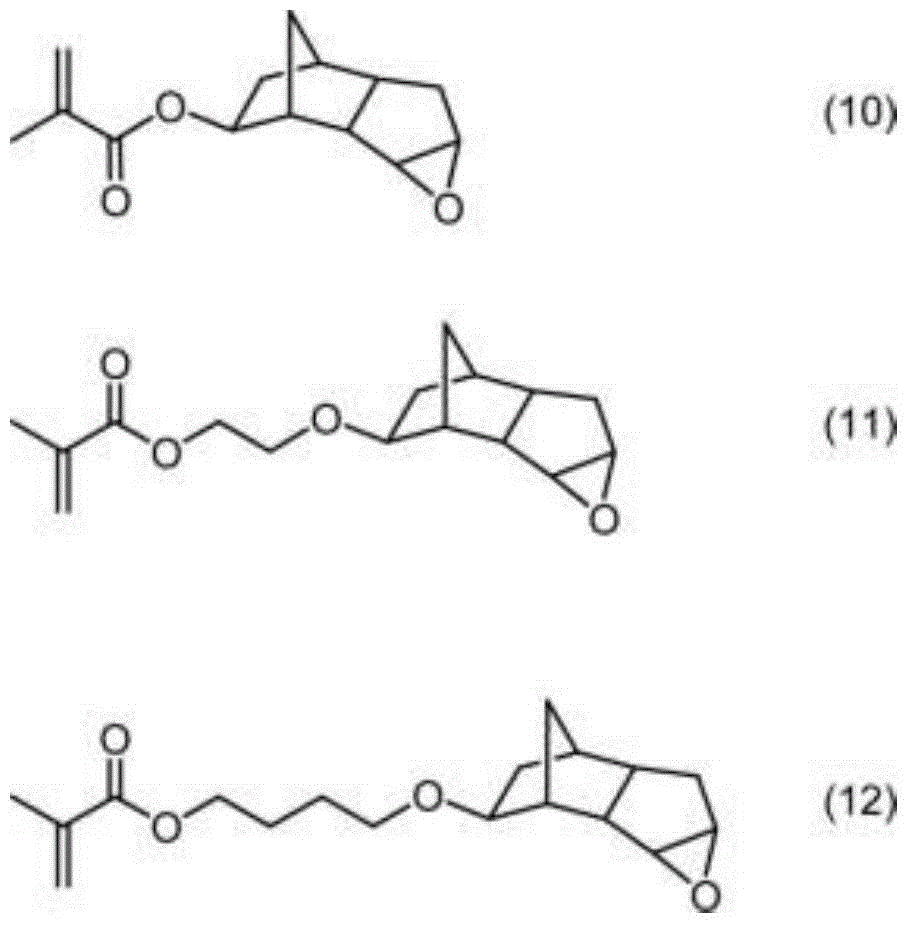

The invention discloses a photonasty resin composition, relating to the negative type photonasty resin composition. The photonasty comprises a first resin of the repeated unit which is expressed by a certain structure, a binder polymer of the second resin (A), a polymer compound (B), a Polyfunctional thiol compound with more than three functions (C), a photopolymerization initiator (D) and a solution (E). The first resin is mixed with the second resin according to a weight ratio of 50:50-90:10, so that the pattern having an excellent reaction and durance is formed under the low temperature curing condition.

Description

technical field [0001] The present invention relates to a photosensitive resin composition, and more specifically, to a photosensitive resin composition capable of forming a pattern excellent in reactivity and durability even under low-temperature curing conditions. Background technique [0002] In the display field, the photosensitive resin composition is used to form various photocurable patterns such as photoresists, insulating films, protective films, black matrices, and columnar spacers. Specifically, the photosensitive resin composition is selectively exposed and developed by a photolithography process to form a desired photocuring pattern, but in this process, in order to improve the yield of the process and improve the physical properties of the application object, it is required to have high Sensitivity photosensitive resin composition. [0003] The patterning of the photosensitive resin composition utilizes a photolithography method, that is, a change in polarity ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03F7/038G03F7/00

Inventor 赵庸桓全吉敏朴汉雨

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com