Processor for defective cigarettes

A technology for cigarette sticks and cigarette holders, which is applied in the field of planing and cutting devices to achieve the effects of convenient use, saving manpower and material resources, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

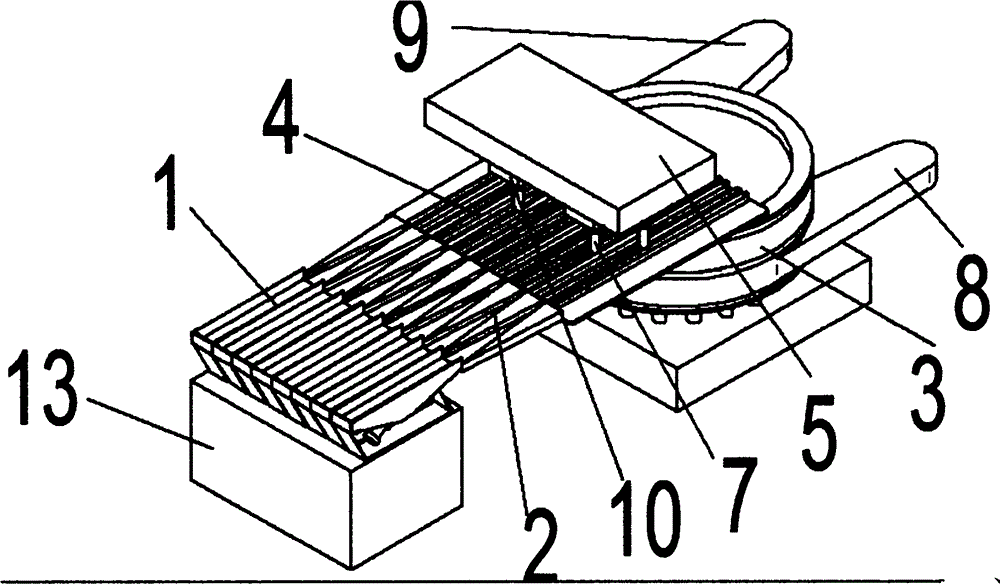

[0022] figure 1 A new type of waste smoke treatment machine is shown in the form of a schematic perspective view of the waste smoke processor. The waste smoke processor consists of 5 parts: feeder 1, smoke distribution slide 2, belt conveying part 4, knife control part 5, shredded tobacco, soot separator 3.

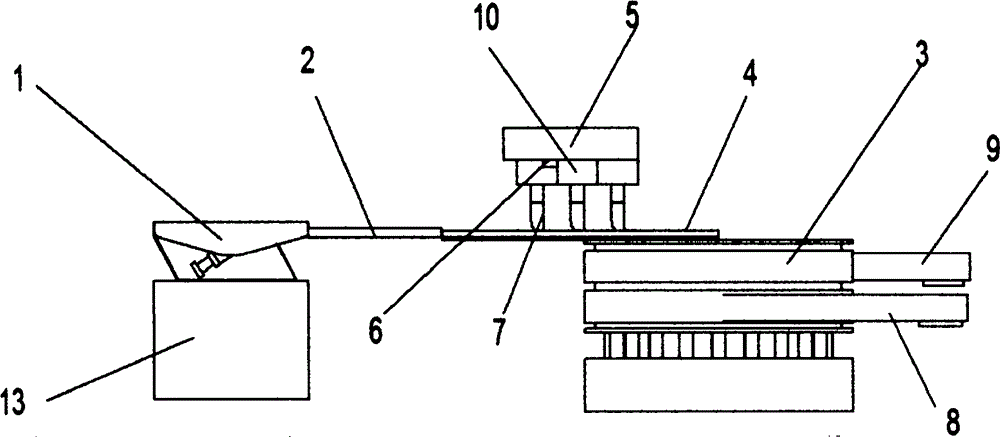

[0023] figure 2 The working principle process of the invention is shown in the form of a schematic front view of the waste smoke processor. Put the discarded cigarettes into the feeding unit 1, lead the cigarettes out from the outlet through vibration, and the cigarettes enter the cigarette distribution slide 2; the cigarette distribution slide 2 uses the shape of the slide to position the cigarettes one by one, which is convenient for the cigarette The cigarettes enter the belt conveying part 4, and the cigarette branch chute 2 is powered by vibration to move the cigarette branch forward; after the axially positioned cigarettes leave the cigarette separating chute 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com