A carbon fiber fishing rod waste shredder

A fishing rod and crusher technology, applied in the field of carbon fiber waste recycling equipment, can solve problems such as failure to achieve environmental protection production, inability to popularize applications on a large scale, pollution, etc., achieve low manufacturing and maintenance costs, easy extraction and utilization, and expand development prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

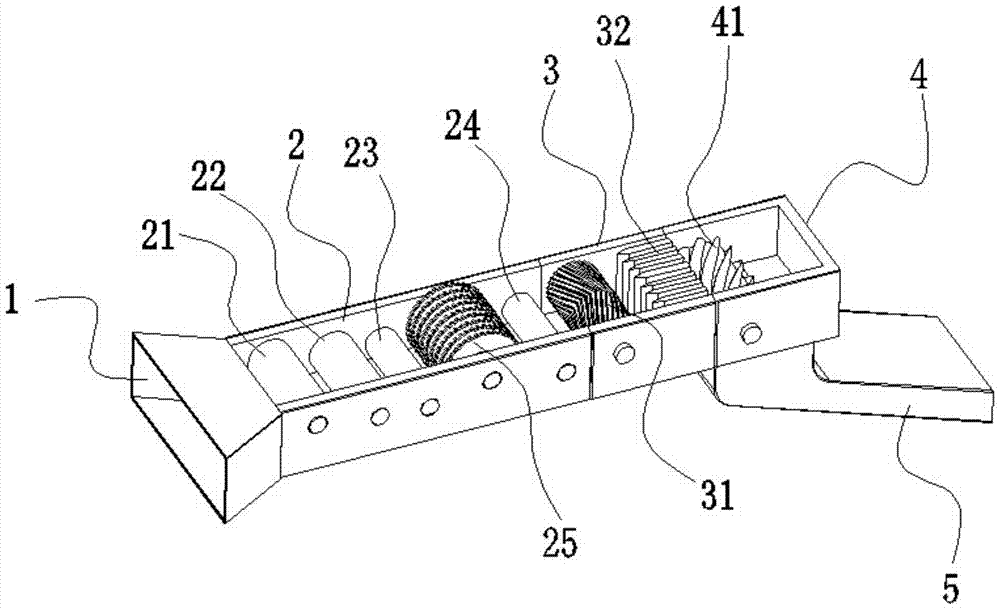

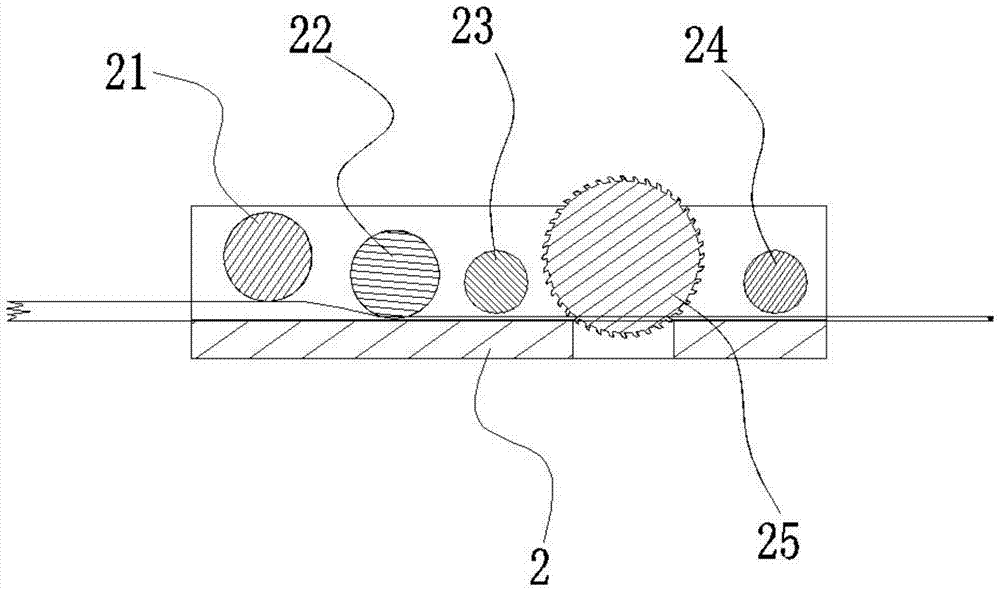

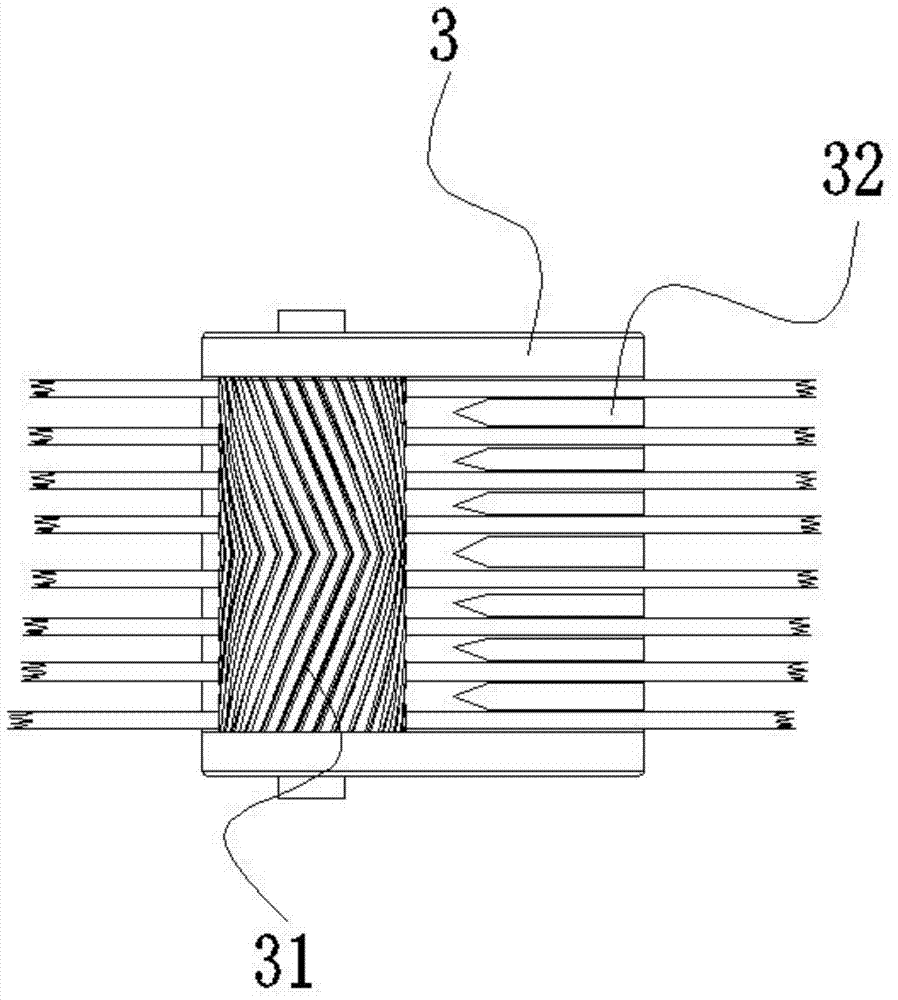

[0014] Such as figure 1 As shown, a carbon fiber fishing rod waste crusher includes a feed inlet 1, a crushing bin 2, a split bin 3, a cutting bin 4, and a discharge port 5. The crushing bin 2 is provided with a first rolling roller 21 , The second rolling roller 22, the first transfer roller 23, the second transfer roller 24 and the fragment width limiting knife roller 25; the axis of the first transfer roller 23 and the second transfer roller 24 are parallel to the bottom surface of the crushing bin 2, and The bottom surface of the crushing bin has a certain distance. The distance between the second rolling roller 22 and the bottom surface of the crushing bin 2 is less than the distance between the first rolling roller 21 and the bottom surface of the crushing bin 2. The first transfer roller 23 and the second transfer roller 24 They are respectively distributed on both sides of the fragment width limiting knife roller 25; the fragment width limiting knife roller 25 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com