Monomer filter well

A filter well and monomer technology, which is applied in the direction of filtration treatment, water/sludge/sewage treatment, drainage structures, etc., can solve the problems of large differences in on-site pouring, difficulty in meeting design standards, general filtration and separation effects, etc., and achieve reduction On-site construction labor time and labor intensity, the effect of reducing the impact of traffic and life, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

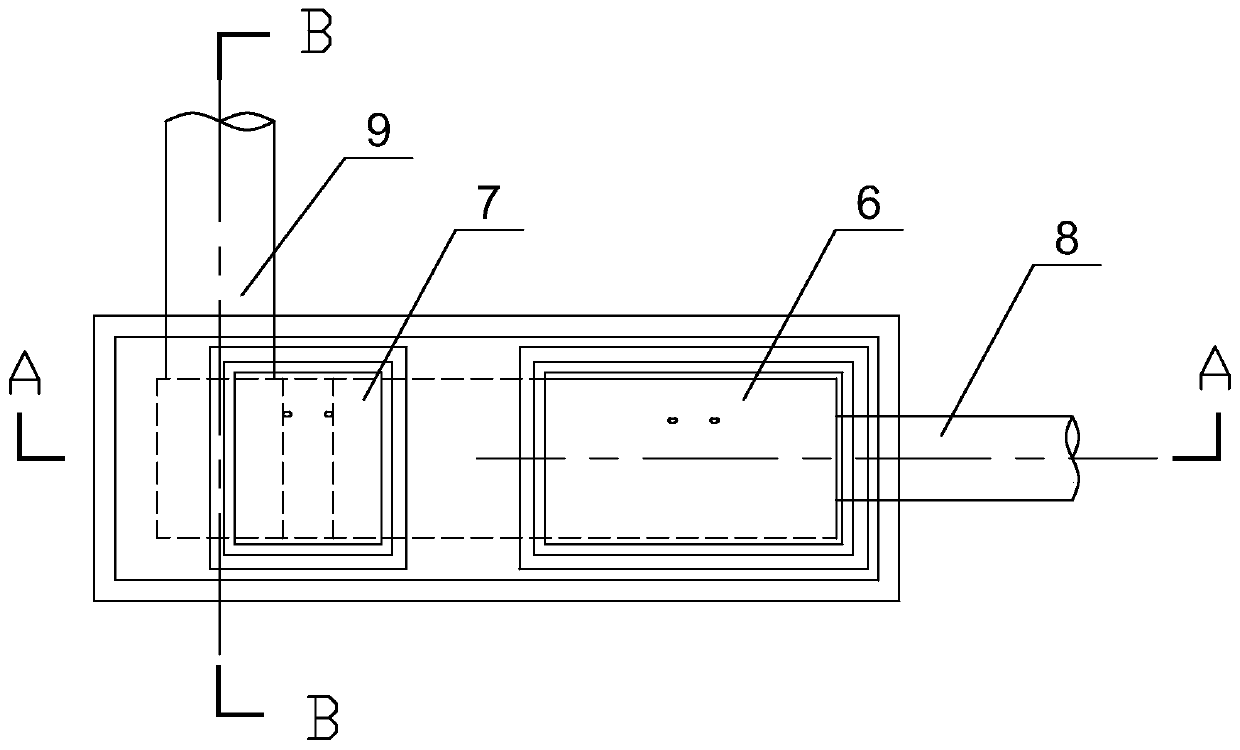

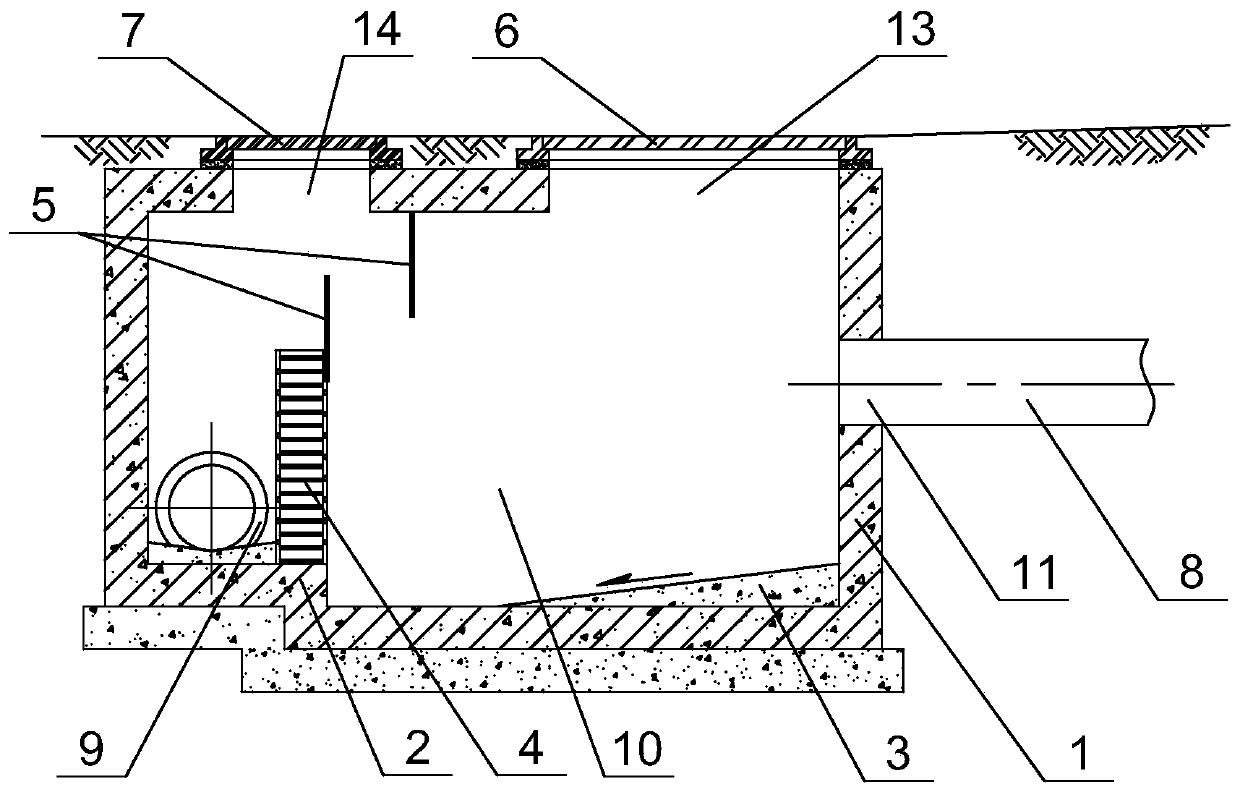

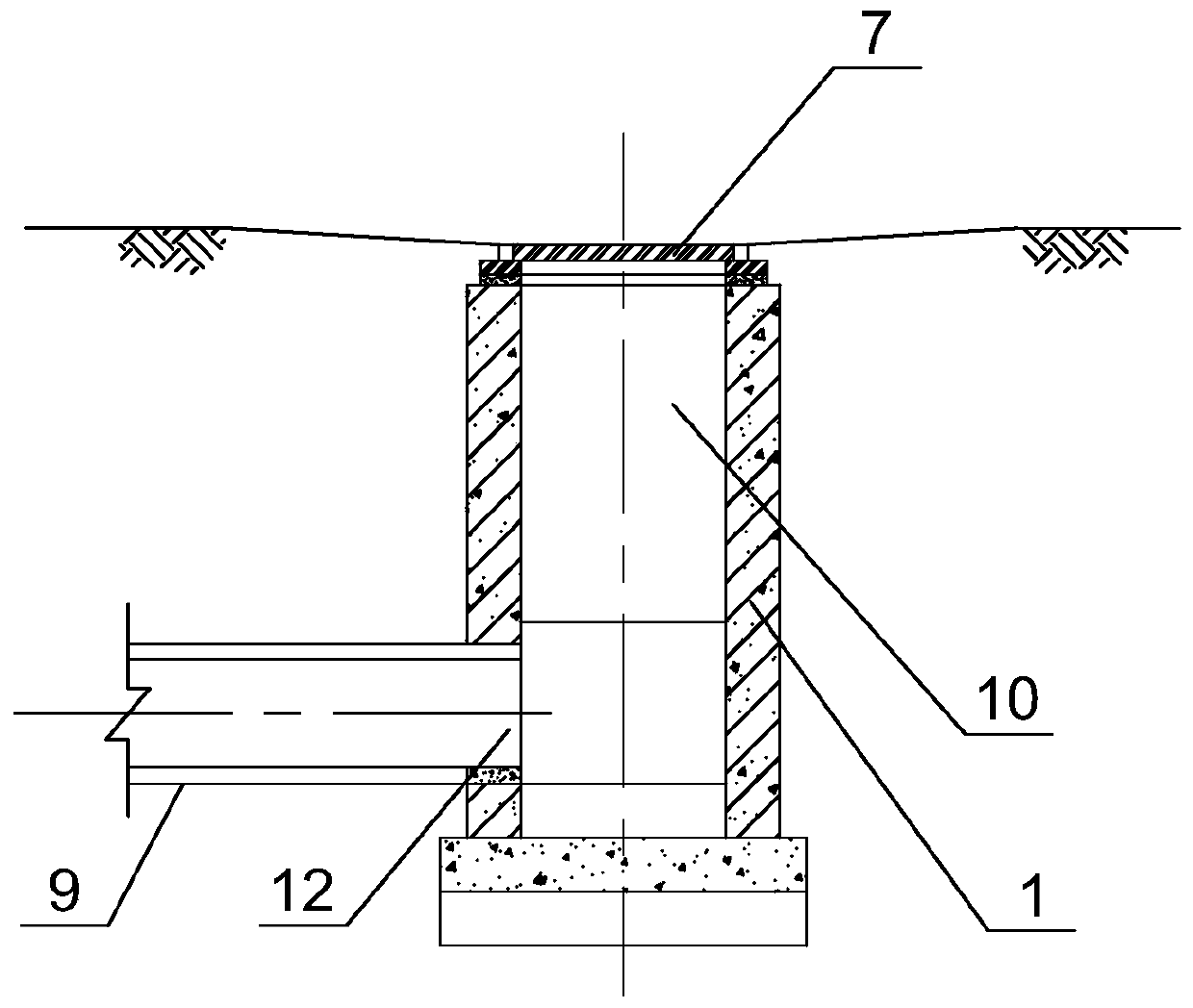

[0016] Such as Figure 1 ~ Figure 3 As shown, the monomeric filter well of this embodiment includes a monomeric box body 1, and the inside of the box body 1 is a filter chamber 10, and the side walls of the box body 1 are respectively provided with water inlets 11 for connecting to the water inlet pipe 8. . The water outlet 12 for connecting the water outlet pipeline 9, the water inlet 11 is higher than the water outlet 12, the bottom of the box 1 is provided with a step 2, and the step 2 is provided with a trap for oil separation and filtration Oil-separating and oil-absorbing frame 4, porous ecological cotton is arranged in described oil-separating and oil-absorbing frame 4, and the bottom of described casing 1 is provided with slope 3, and described slope 3 is from the sidewall of described water inlet 11 to described step 2 The direction is inclined to settle the oil sludge. The slope of the slope 3 is 1% to 5%. The baffles 5 are partially overlapped in height to form a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com