Chip tracking type automatic telescopic chip remover

A tracking and automatic sorting technology, applied in metal processing machinery parts, turning equipment, maintenance and safety accessories, etc., can solve problems such as inability to eliminate, low work efficiency, danger, etc., to reduce labor intensity and danger, and eliminate Enhanced chipping ability and fully automated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

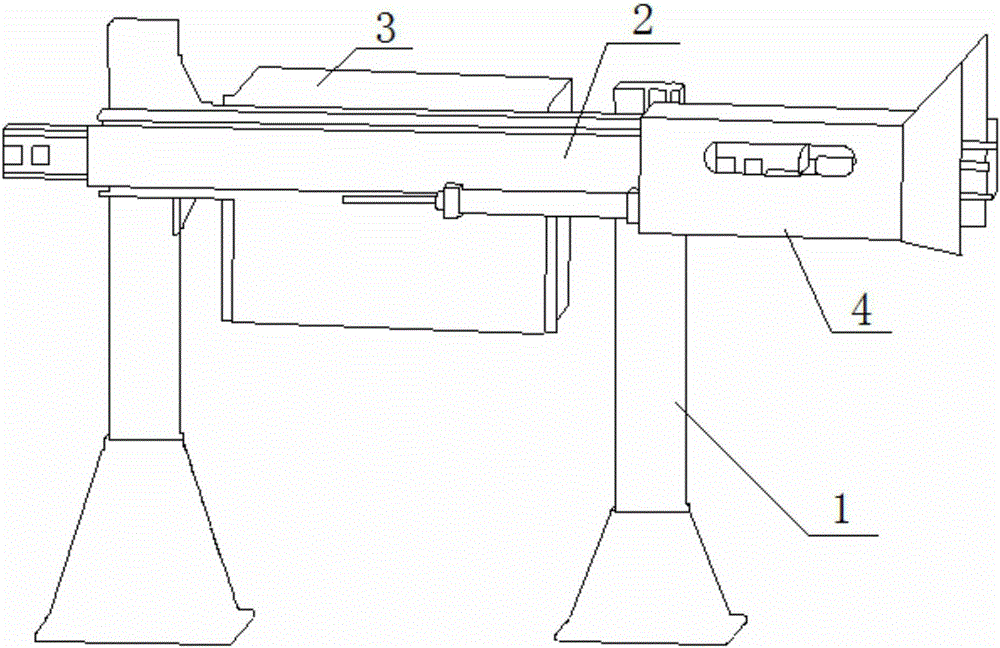

[0018] Such as figure 1 As shown, the present invention is a chip tracking type telescopic automatic chip removal machine. The chip removal machine includes a bracket 1, a module 2, a control electric cabinet 3 and a chip removal system 4. The module 2 is horizontally installed on the bracket 1, and the control electronics The cabinet 3 is installed on the bracket 1, the control electric cabinet 3 is located on the side of the module 2, the control electric cabinet 3 is used to control the module 2 and the chip removal system 4, and the chip removal system 4 is installed on the module 2.

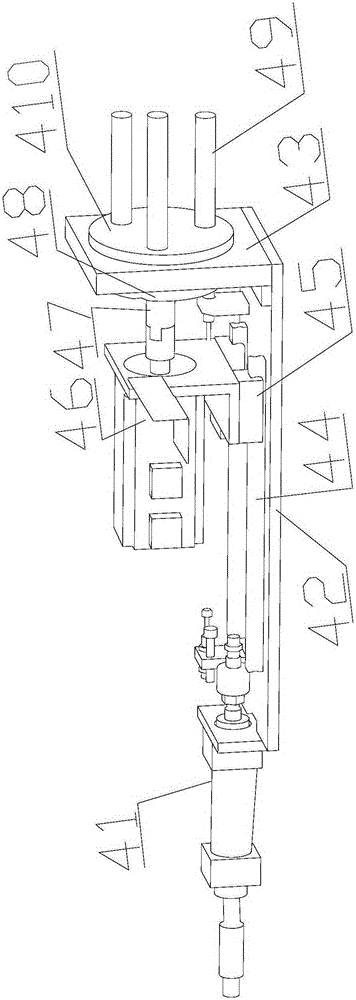

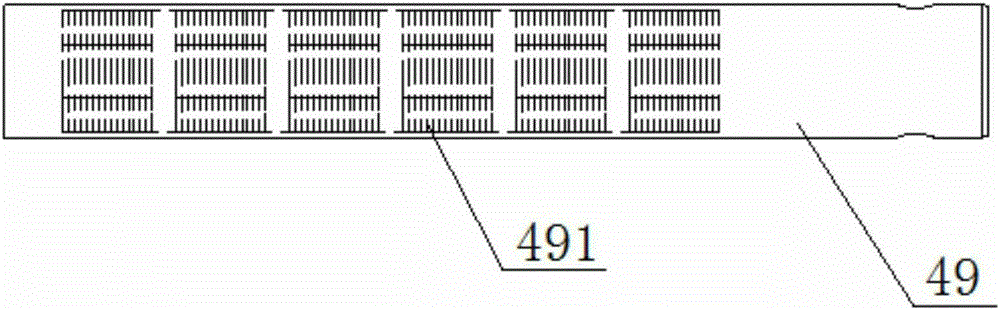

[0019] Such as figure 2 As shown, the chip removal system 4 includes a cylinder 41, a chip removal line rail bottom plate 42, a bearing seat 43, a linear guide rail 44, a chip removal servo motor fixing plate 45, a chip removal servo motor 46, a universal coupling 47, a rotating shaft 48, The chip rolling key 49 and the chip rolling shaft 410, the cylinder 41 are installed on the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com