a reamer

A reamer and blade technology, applied in the field of reamers, can solve problems such as low machining efficiency, reduced tool life, and impact on workpiece quality, and achieve the effects of improving processing quality, prolonging service life, and ensuring chip removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

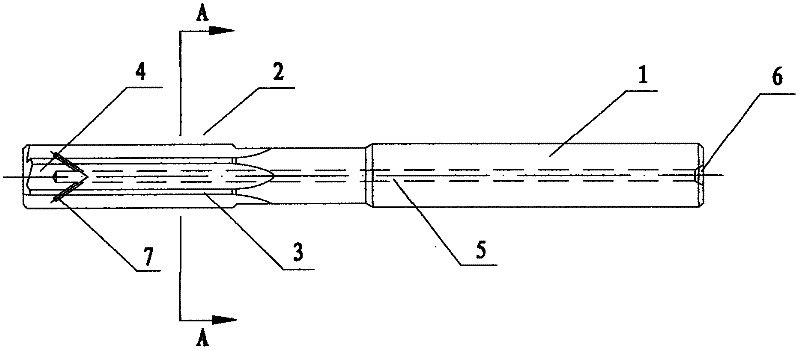

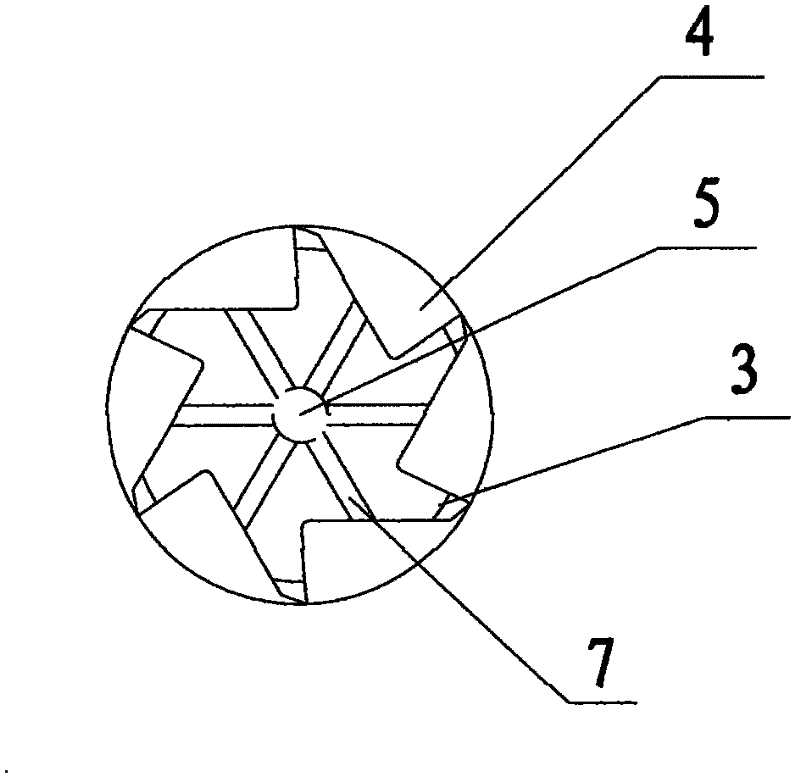

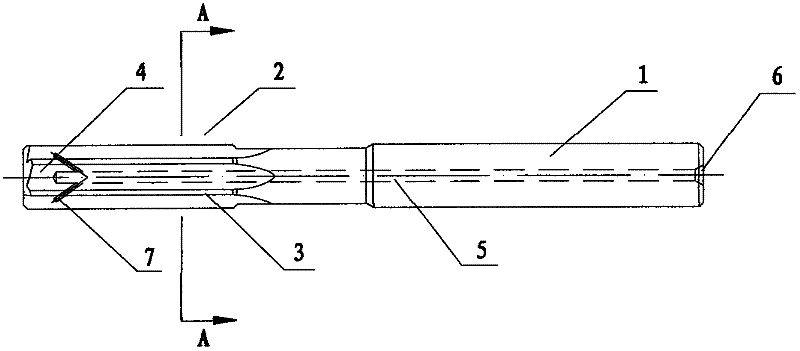

[0015] like figure 1 , 2 As shown, the reamer of this embodiment is processed by using a CNC five-axis linkage grinding machine and independently programming the tool program. The base material is made of hard alloy, and the surface is provided with TIALN-XC coating. Specifically, the reamer includes a shank 1 and a blade 2. The blade 2 is provided with a plurality of side edges 3, and chip removal grooves 4 are arranged between adjacent side edges 3. There is a connected internal cooling hole 5, one end of the internal cooling hole 5 is connected to the water inlet hole 6 provided at the end of the handle 1, and the other end of the internal cooling hole 5 is connected to the drain hole 7 provided in the chip removal groove 4 Connected, the pipeline between the internal cooling hole 5 and the drain hole 7 faces the end of the blade portion 2 .

[0016] During processing, inject cooling water into the reamer through the water inlet hole 6 provided at the end of the shank 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com