Small drill

一种钻头、小型的技术,应用在修钻、麻花钻、钻具附件等方向,能够解决不能形成、无法实现排出切屑、切屑排出性能恶化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

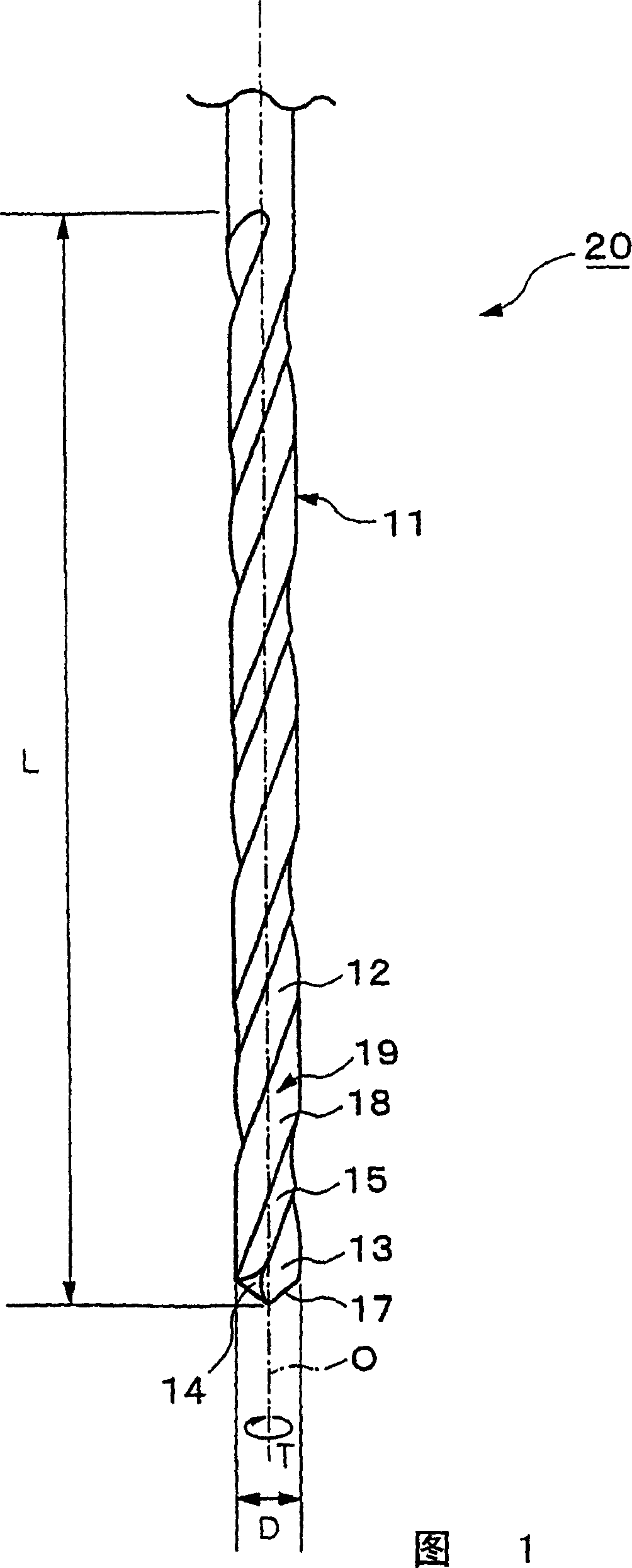

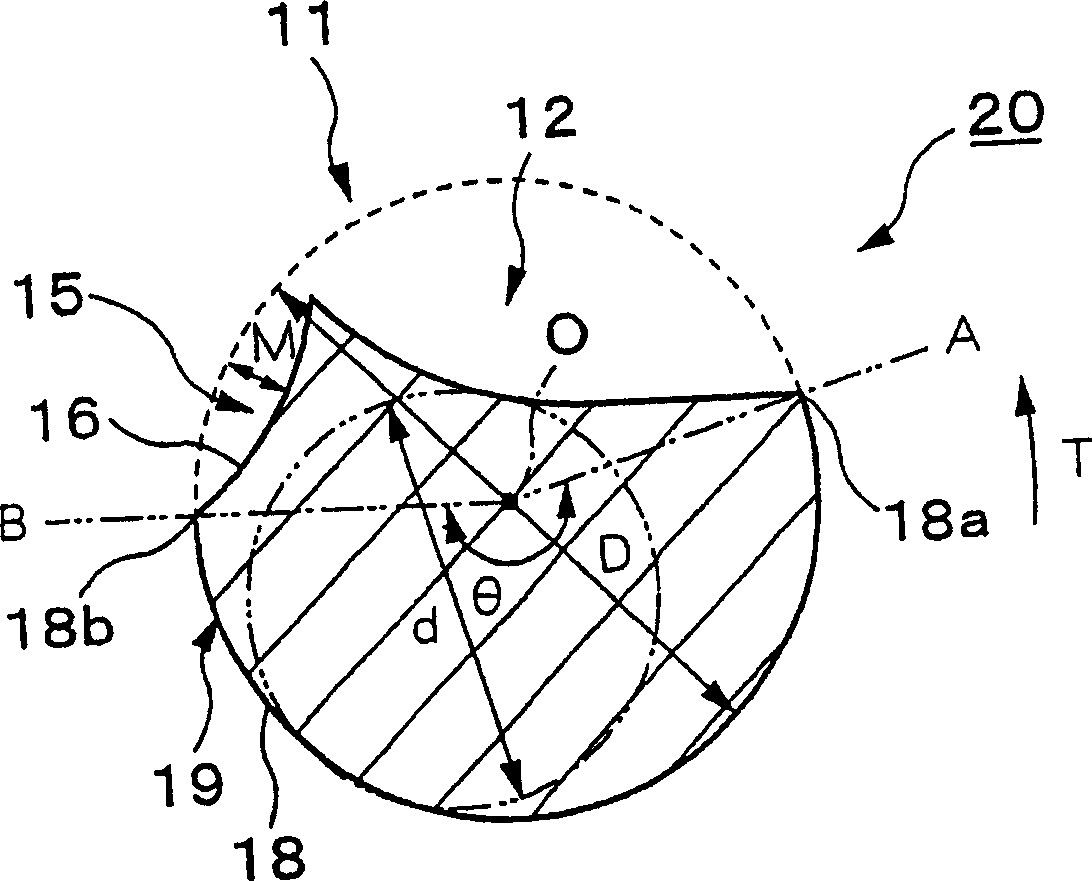

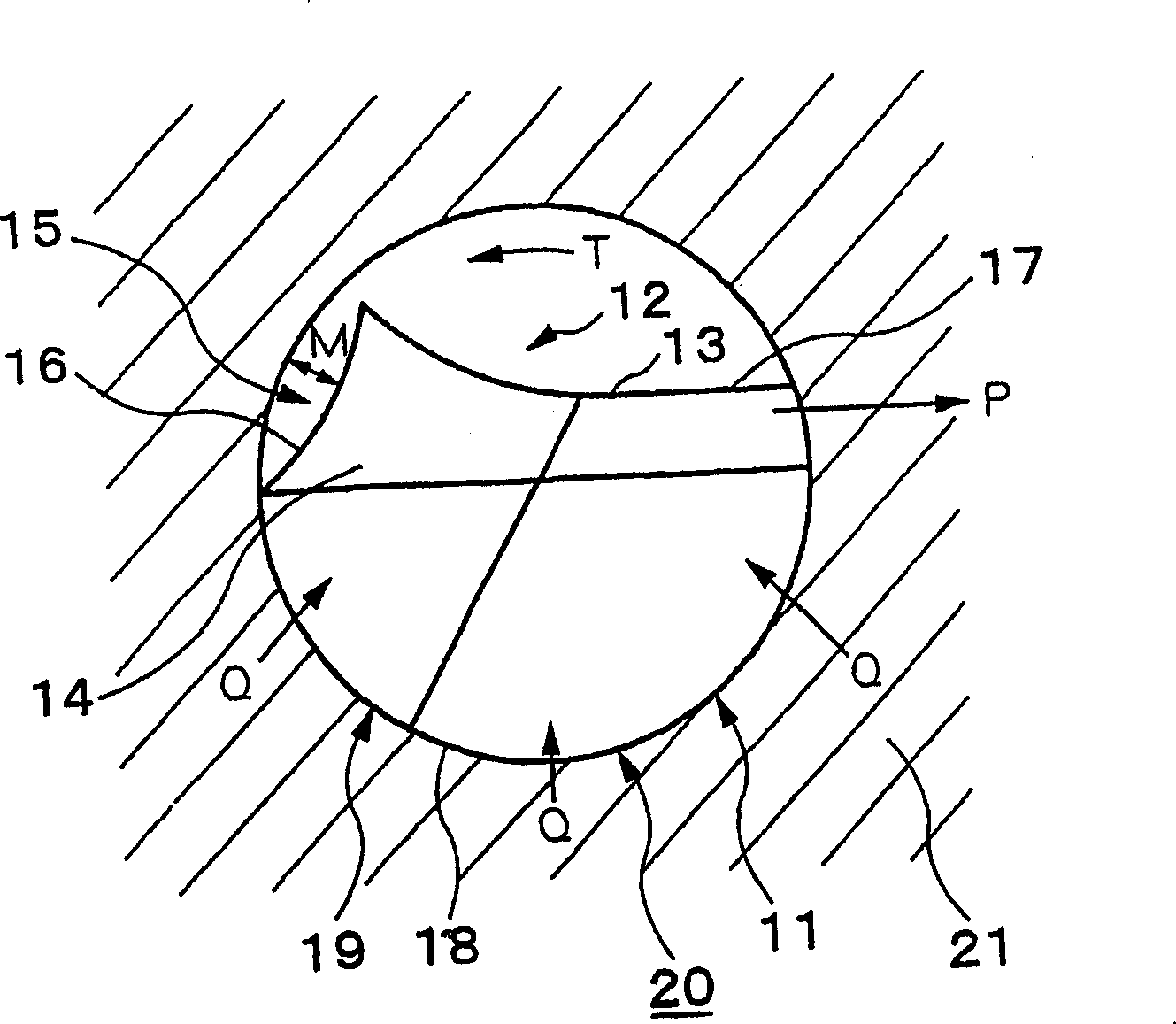

[0070] A small drill that is an example of the present invention is used as Experimental Examples 1 to 5, a small drill with a core thickness ratio d / D smaller than the above-mentioned range of the present invention is used as Comparative Example 1, and a small drill with a complementary angle θ smaller than the above-mentioned range of the present invention is used as a comparative example 2. As a conventional example, a small drill with two chip discharge grooves 12 provided at the tip 11 is used as conventional example 1, and a small drill with one chip discharge flute 12 provided at the tip 11 but without a grooved portion 15 is used. Small drills were used as Conventional Examples 2 to 4, and drilling tests of workpieces were performed using these examples. In addition, in Experimental Examples 1 to 5, Comparative Examples 1 and 2, and Conventional Example 1, the helix angle of the chip discharge flute 12 was 40°, while in Conventional Examples 2 to 4, the helix angle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com