Independently moving type vacuum sucker provided with airlock and board suction device

A vacuum suction cup, mobile technology, applied in the direction of wood processing equipment, multi-purpose machinery, manufacturing tools, etc., can solve the problems of troublesome bolt connection, no self-lubricating mechanism, production accidents, etc., and achieve beautiful structure and good working stability , The effect of convenient processing and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

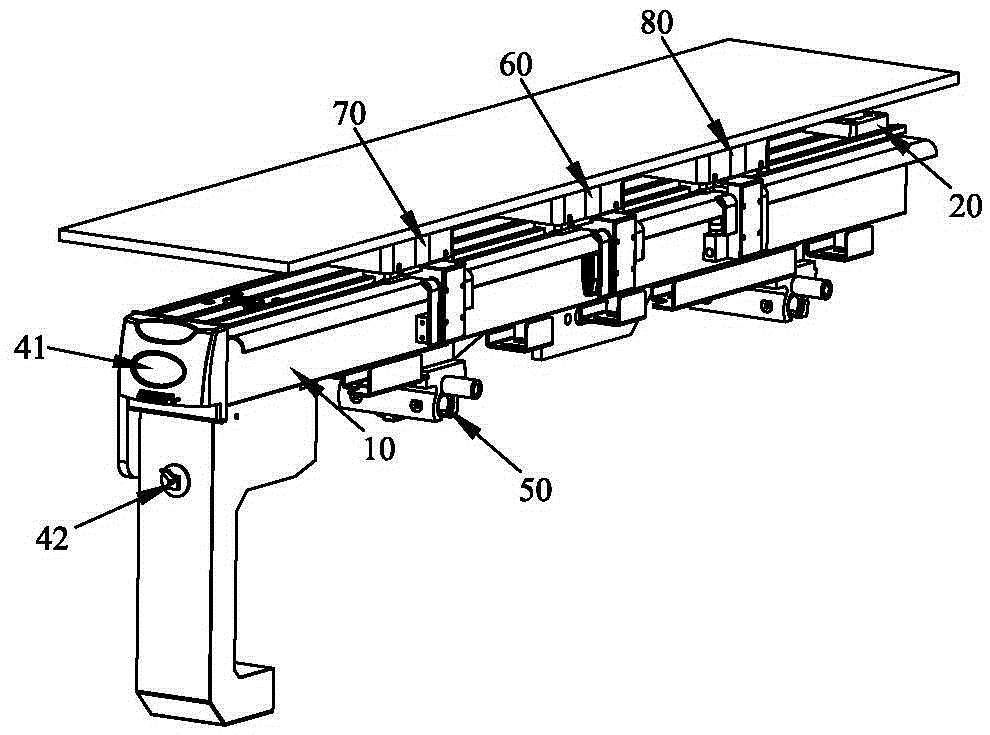

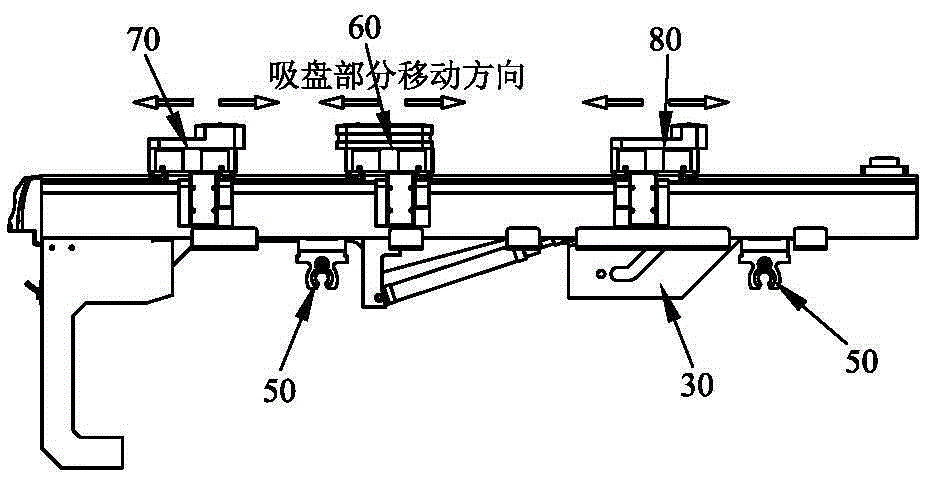

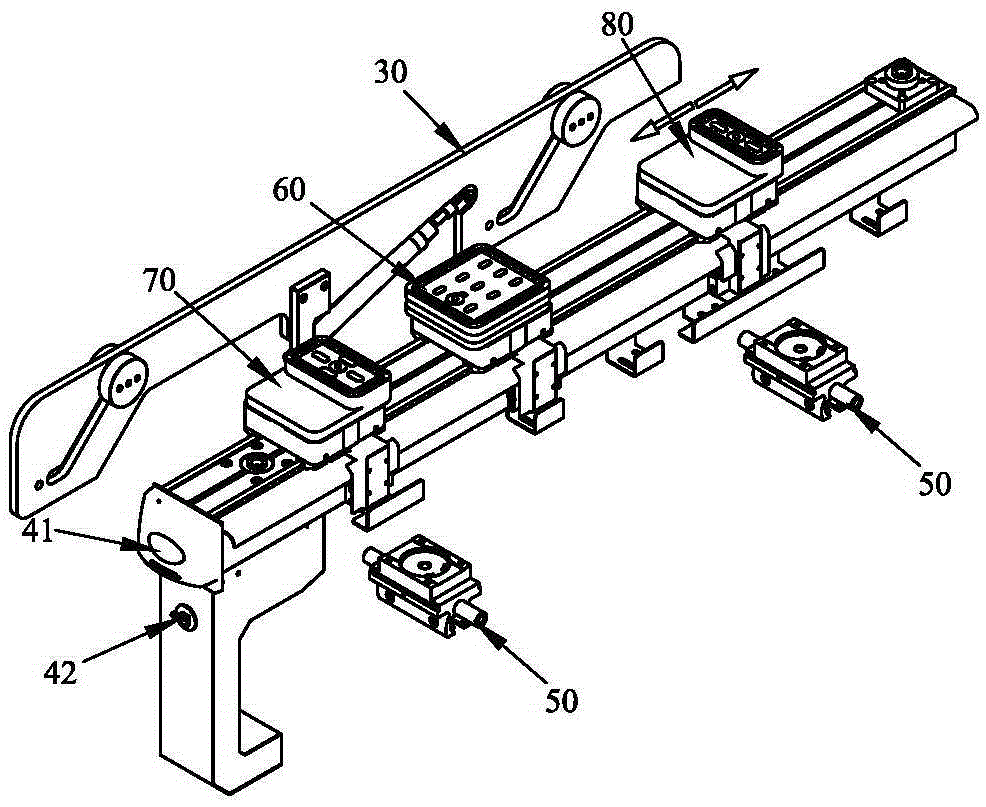

[0047] Please refer to Figure 1 to Figure 5 As shown, it has shown the specific structure of a preferred embodiment of the present invention, which is a plate adsorption device with an air lock type independent movable vacuum chuck. Its structure includes a mobile workbench 10, and Positioning cylinder 20, suction cup top loose mechanism 30, mobile sliding mechanism 50, multiple vacuum suction cups are installed on this mobile workbench 10, in the present embodiment, comprise No. 1 suction cup 60, No. 2 suction cup 70, No. 3 suction cup 80, But the quantity of sucker is not limited to this.

[0048]Wherein, a plurality of vacuum suction cups can freely move back and forth independently on the mobile worktable 10, and each vacuum suction cup has an air lock structure and a vacuum pipeline follow-up movement mechanism for independently locking the mobile workbench 10. The positioning cylinder 20 installed at the front and rear ends of the mobile workbench 10 is used for proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com