Installation structure of sludge thickener

A technology of installation structure and thickener, applied in the direction of dewatering/drying/concentrated sludge treatment, etc., can solve the problems of easy clogging of pipelines, easy agglomeration, sludge floating, etc., so as to improve the concentration efficiency, reduce the drying rate, and discharge the sludge. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

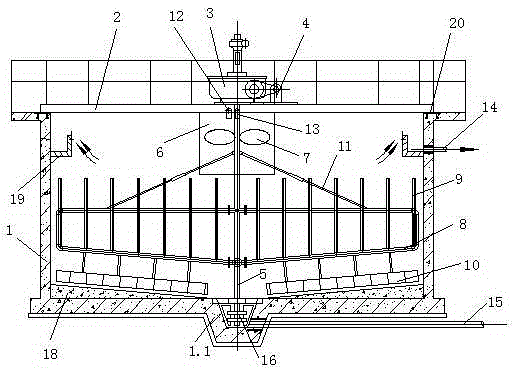

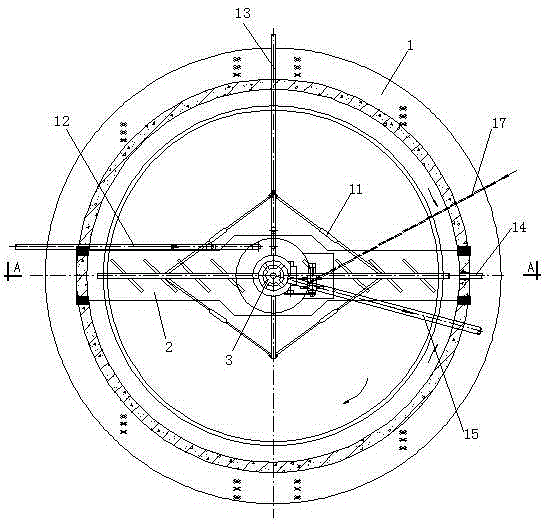

[0013] Embodiment 1: a kind of sludge thickener installation structure, comprises circular pool body 1, is installed in the sludge thickener in circular pool body 1, and circular pool body 1 top is provided with working bridge 2, and the center of working bridge 2 A vertical worm gear reducer 3 is installed, the reducer 3 is connected to the motor 4 through a pulley, the transmission shaft of the reducer 3 is connected to the stirring shaft 5, the upper end of the stirring shaft 5 is sleeved in the guide tube 6, and the stirring shaft located in the guide tube 6 5 is provided with a stirring blade 7, and the middle section of the stirring shaft 5 is provided with 4 U-shaped wall scraping pipes 8 connected with the stirring shaft 5 around the center of the stirring shaft 5. The upper end of the bottom pipe of the U-shaped wall scraping pipe 8 is arranged at intervals with vertical The upward grid bar 9, the lower end of the bottom pipe is connected with a mud scraper 10, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com