A performance-adjusting admixture of magnesium phosphate cement-based composite material

A technology of magnesium phosphate cement and composite material, applied in the field of building materials, can solve the problems of difficult setting time of magnesium phosphate cement, poor environmental applicability, poor volume stability, etc., and achieves benefits of sustainable development, low cost, and simple components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

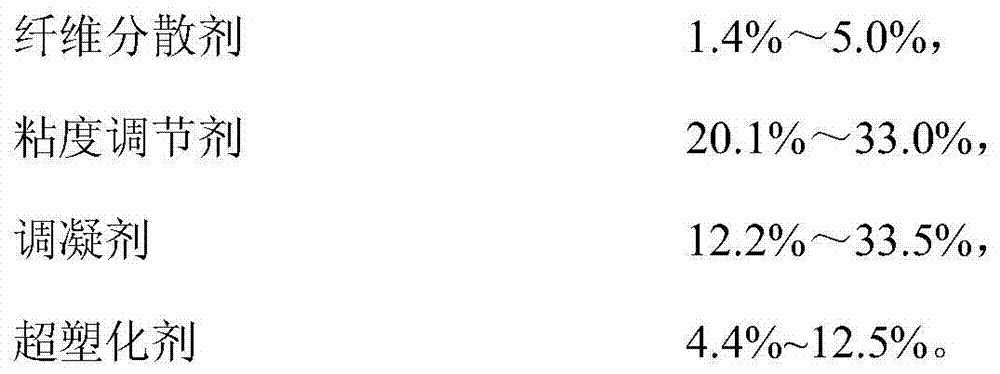

Method used

Image

Examples

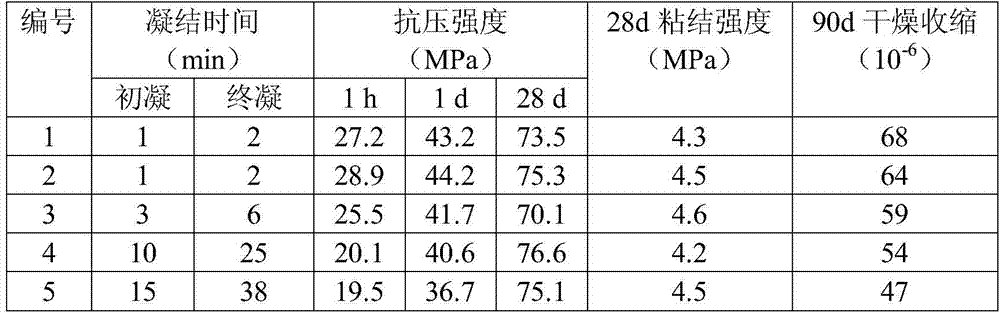

Embodiment 1

[0033]Weigh 15.6% of calcium oxide expansion agent, 6.9% of polyalcohol shrinkage reducer, 12.8% of polypropylene fiber, 1.8% of hydroxypropyl methylcellulose, 30.0% of organic silicon viscosity reducer, 23.7% of magnesium chloride hexahydrate, superplastic 9.2% chemical agent, mixed evenly, packed for later use.

Embodiment 2

[0035] Weigh 13.2% of magnesium oxide expansion agent, 6.3% of polyether shrinkage reducer, 14.3% of glass fiber, 3.7% of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, and 26.4% of organic polyether viscosity reducer , 27.4% copper chloride, 8.7% superplasticizer, mixed evenly, and packed for later use.

Embodiment 3

[0037] Weigh 12.2% of calcium oxide expansion agent, 5.3% of polyether shrinkage reducer, 14.9% of polyethylene fiber, 3.0% of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, 25.9% of organic silicon viscosity reducer, Calcium chloride 30.2%, superplasticizer 8.5%, mix uniformly, carry out packaging and stand-by.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com