6063-T5 aluminum profile two-stage energy-saving aging process

A double-stage aging and aluminum profile technology, which is applied in the field of artificial aging of aluminum profiles, can solve the problems of high energy consumption and high cost of artificial aging, and achieve the effects of shortening the artificial aging time, increasing the tensile strength at room temperature, and increasing the yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

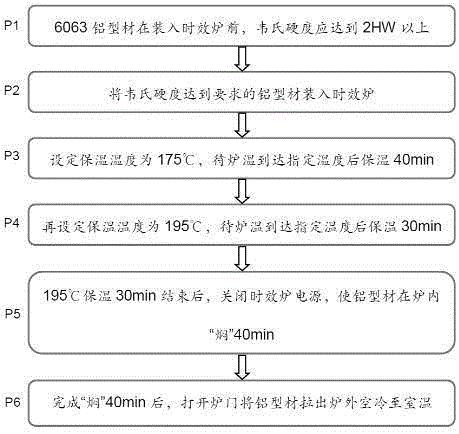

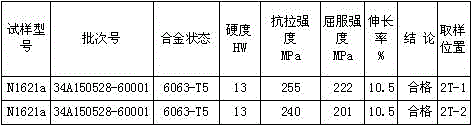

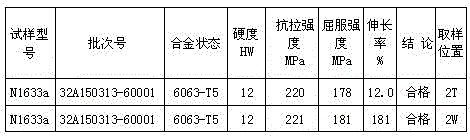

Embodiment 1

[0029] In this example, according to the two-stage energy-saving aging process in the present invention, the 6063-T5 profile of the model N1621a is aged, and the mechanical properties after aging are qualified. The details are as follows: P1. The side widths of the strips are quite different, and the spacing between the profiles can meet the requirements of hot air circulation during the aging process without being too large. Before loading into the aging furnace, the measured value of Webster's hardness is in the range of 2HW to 4HW. P2. The distance between the profile and the top of the aging furnace should be about 50cm, and the distance between the material baskets should be about 30cm. P3. During the double-stage energy-saving aging process test, the temperature accuracy of the aging furnace has been measured many times, which meets the process requirements of ±5°C. After loading the profiles into the aging furnace, set the holding temperature at 175°C. Before the agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com