Sacrificial anode structure and method for checking corrosion state of sacrificial anode structure

A sacrificial anode and corrosion state technology, which is applied in the field of sacrificial anode structure and its corrosion state inspection, can solve the problems of high cost, affecting the life of threaded joints, fast corrosion rate, etc., and achieve simple structure, increased service life, and low manufacturing level requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

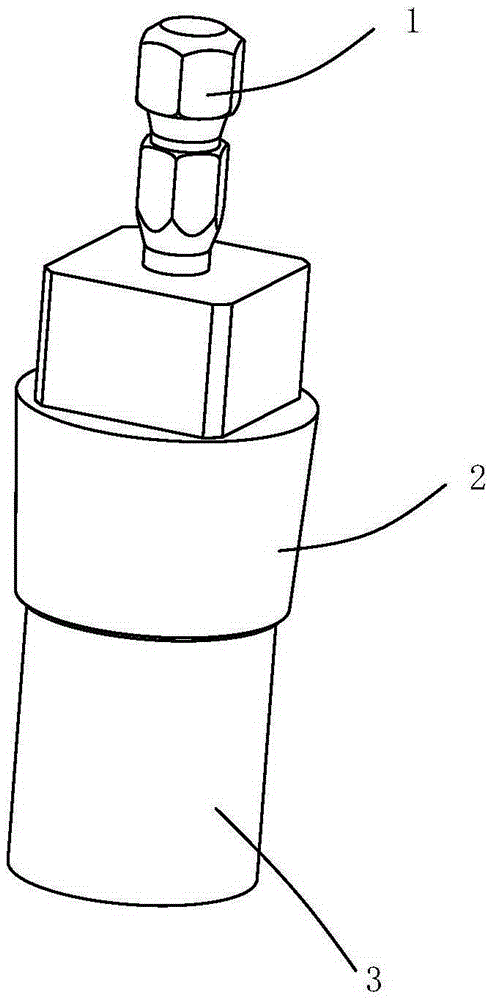

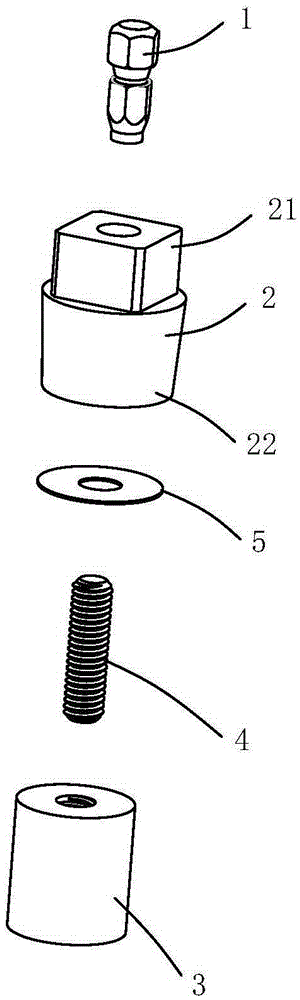

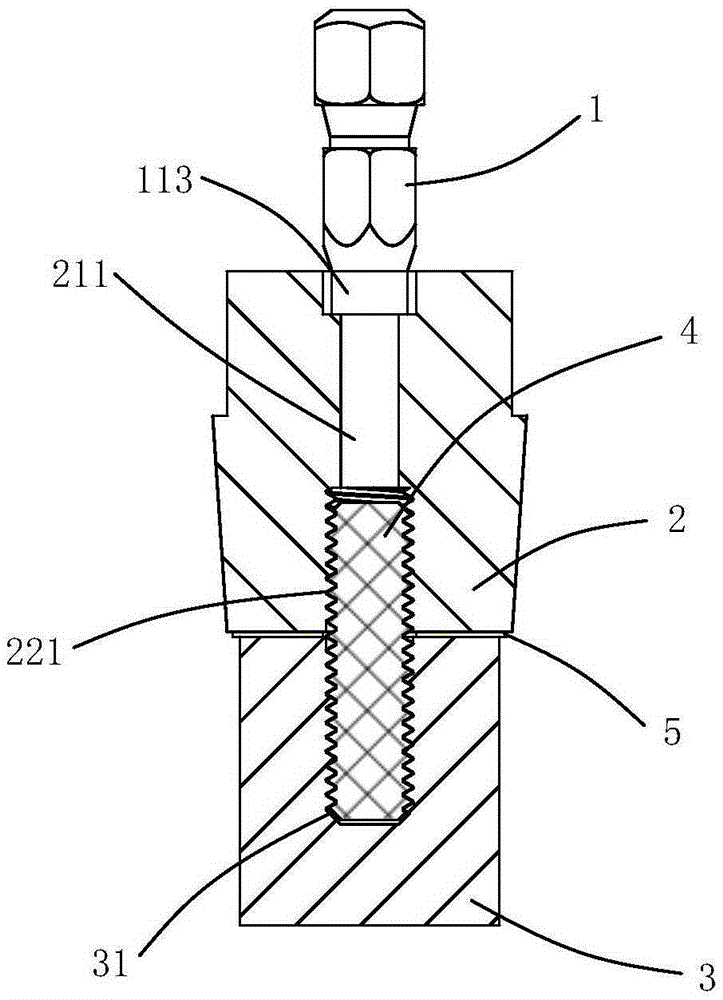

[0022] Such as figure 1 , 2 As shown, the sacrificial anode structure of the present invention includes an inspection head 1, a screw plug 2, a corrosion block 3 and a mandrel 4, the inspection head 1 is fixedly connected to one end of the screw plug 2, and the corrosion block 3 passes through the core The rod 4 is connected to the other end of the screw plug 2 , preferably, a sealing ring 5 is provided between the corrosion block 3 and the screw plug 2 . In another embodiment, the screw plug 2 and the corrosion block 3 may also be connected by other forms, such as by rivets.

[0023] Such as figure 2 , 3 As shown, the screw plug 2 includes a mounting portion 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com