An anti-insect gas stove

A gas stove and insect-proof technology, which is applied in the field of stoves and achieves a good effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

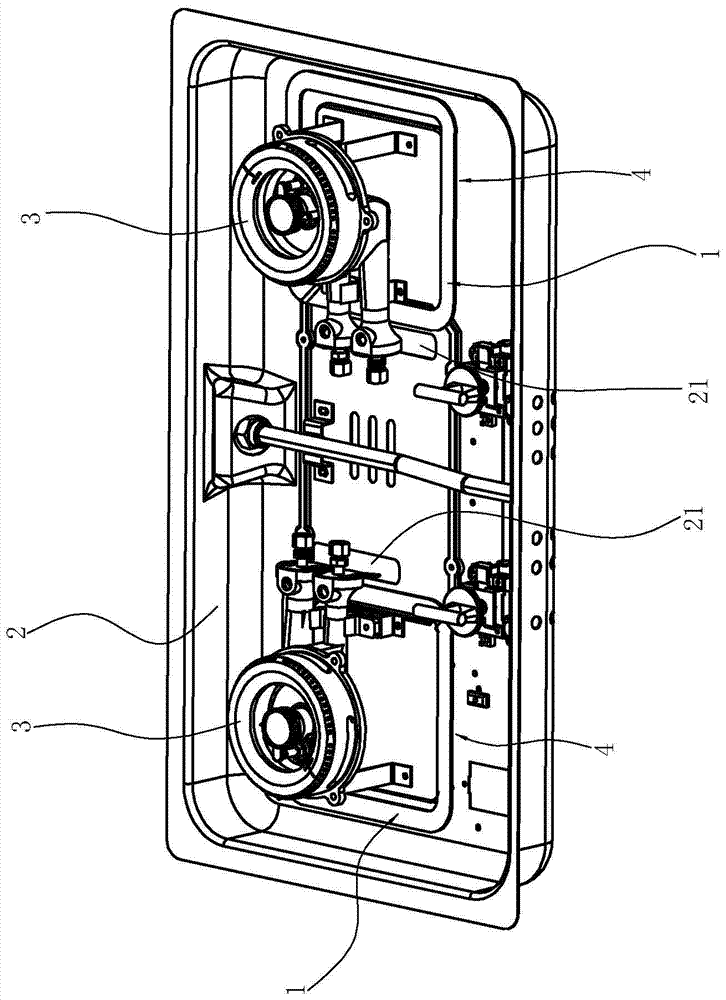

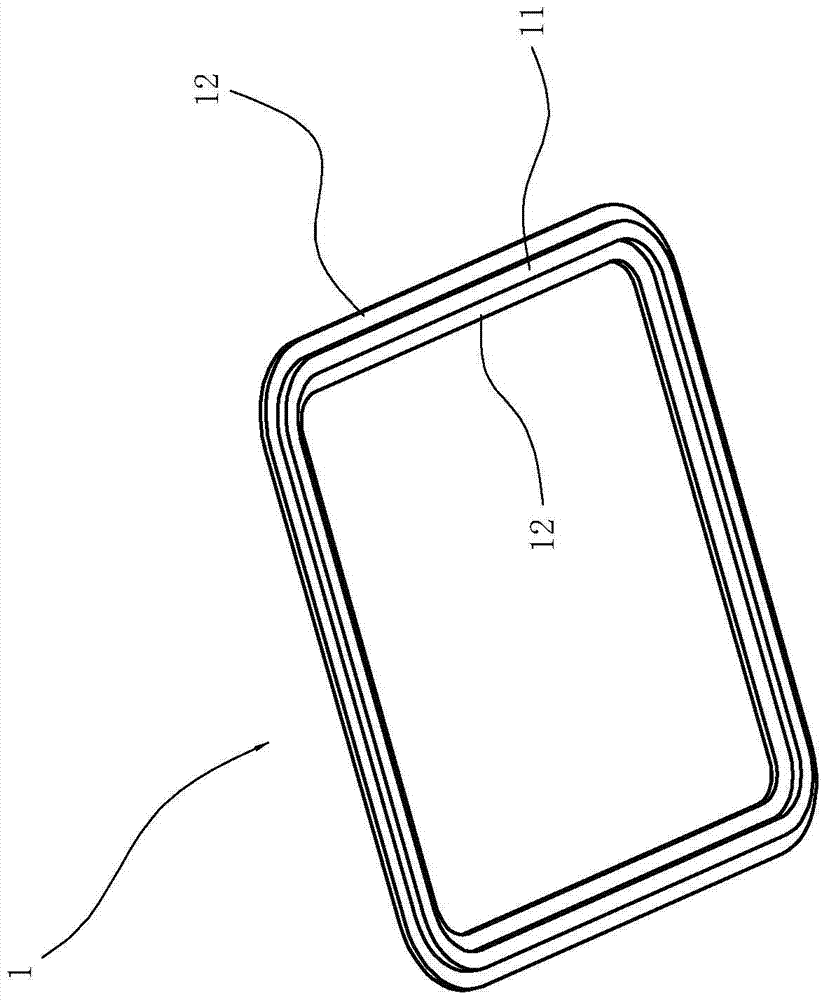

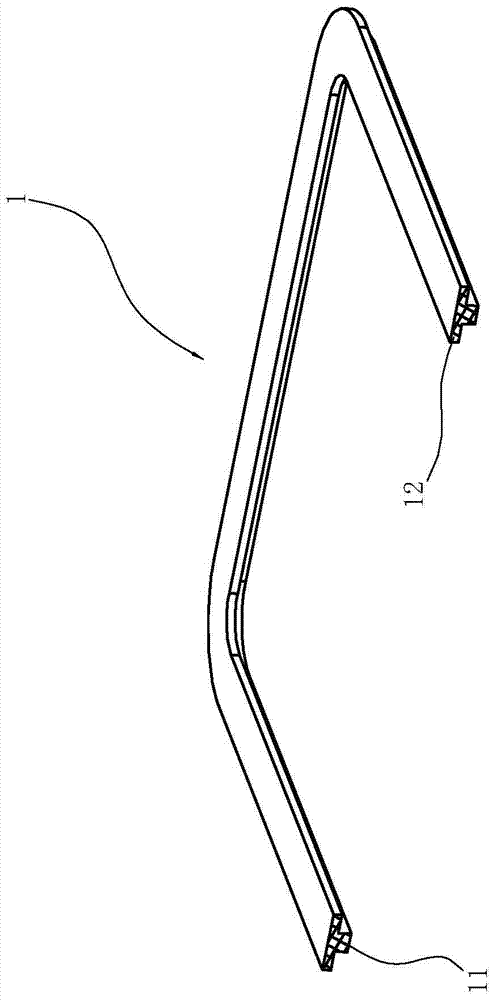

[0022] Such as Figure 1 to Figure 3 As shown, the insect-proof gas stove includes an insect trap 1, and the insect trap 1 in this embodiment includes a ring-shaped base 11, an annular first baffle 12 is connected to the upper surface of the base 11, and the first baffle 12 The two end edges in the length direction protrude outward from the corresponding two end edges on the base 11, and the cross section of the insect trap is in an inverted "convex" shape.

[0023] Insect traps are made of foamed rubber, and there are two, respectively surrounding the outer circumference of the two burners 3 of the gas stove, the size of which is as close as possible to the vent 21 on the bottom shell and does not affect other parts; two insect traps The bases 11 of the components are all pasted on the inner surface of the bottom shell 2 of the gas cooker by double-sided adhesive tape, and a strip-shaped gap 4 is formed between the first baffle plate 12 and the inner surface of the bottom she...

Embodiment 2

[0028] On the basis of the first embodiment, the insect trap 1 in this embodiment is further provided with a second baffle 13 on the base 11 . Such as Figure 4 As shown, the cross-section of the insect trap is in the shape of an "I", and a gap 4 is formed between the first baffle 11 and the second baffle 13 to induce flying insects to cocoon. When in use, the second baffle 13 is pasted on the inner surface of the bottom case by double-sided tape.

[0029] All the other contents are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com