Side-entry backlight module with protection covers

A side-entry backlight and protective cover technology, which is applied in the field of side-entry backlight modules, can solve the problems of lower product assembly yield, damage to the light guide device 7, and stopper falling off, so as to reduce light energy loss and reduce The number of grains and the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

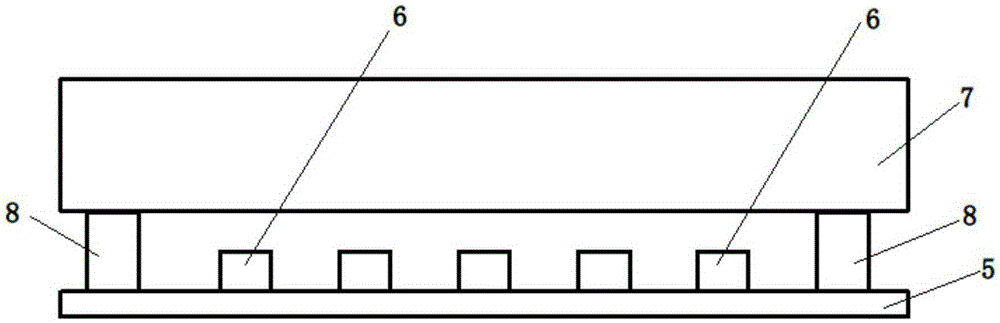

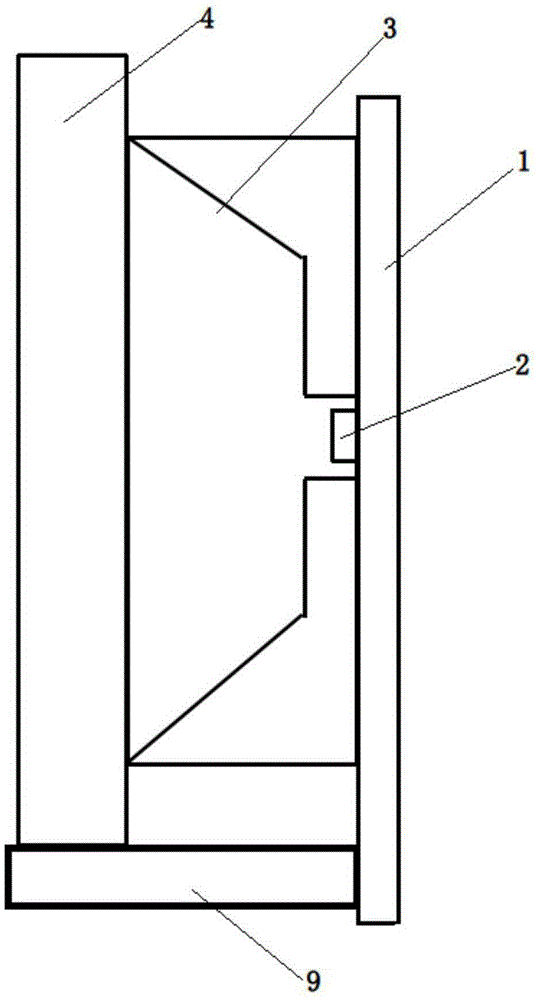

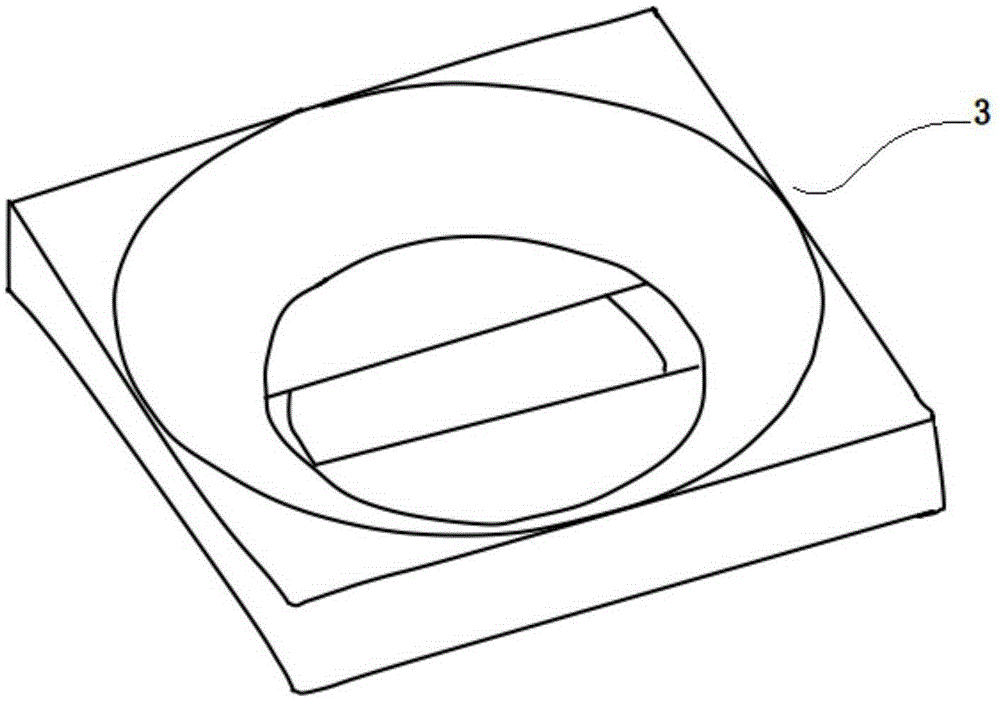

[0022] Example 1: figure 2 The schematic structural diagram of the side-entry backlight module with a protective cover provided by the embodiment of the present invention, it can be clearly seen from the figure that the side-entry backlight module with a protective cover provided by this embodiment includes a light guide plate 4, A light bar and a protective cover 3, the light bar includes a plurality of light sources 2, each light source 2 is provided with a protective cover 3, the protective cover 3 is fixedly installed on the light bar, and the light source 2 is arranged on a corresponding protective cover In the cover 3, the end of the protective cover 3 away from the light bar is provided with a light outlet opening, and the end of the protective cover 3 with the light outlet opening is closely arranged on the light incident surface of the light guide plate 4, wherein the The light source 2 is an LED element, and the light bar also includes a PCB board 1 on which the lig...

Embodiment 2

[0027] Embodiment 2: The difference from Embodiment 1 is that the fixing method of the protective cover 3 and the PCB board 1 is as follows: the PCB board 1 is provided with openings, and the protective cover 3 is provided with openings corresponding to the openings. A positioning post matched with the hole, the positioning post cooperates with the opening to fix the protective cover 3 on the PCB 1 .

[0028] In this embodiment, the distance from the light source 2 in the protective cover 3 to the light incident surface of the light guide plate 4 is 0.2mm, the protective cover 3 is made of plastic or metal material, and each protective cover 3 is made of The metal square body hollowed out in the middle forms the cover body of the protective cover 3 . Other features are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] Embodiment 3: Different from Embodiments 1 and 2, this embodiment does not limit the number of protective covers 3 and light sources 2 to multiples. When a single protective cover 3 and light source 2 are used as a single light-emitting unit, multiple The above-mentioned light-emitting units forming a light bar can also realize the present application. Other features are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com