On-line repairing work processing method of cell

A technology for job processing and battery, applied in the direction of instruments, etc., can solve the problems of rising battery manufacturing cost, declining battery yield, poor appearance and electrical properties, etc., to achieve the effect of facilitating large-scale production, improving production efficiency, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

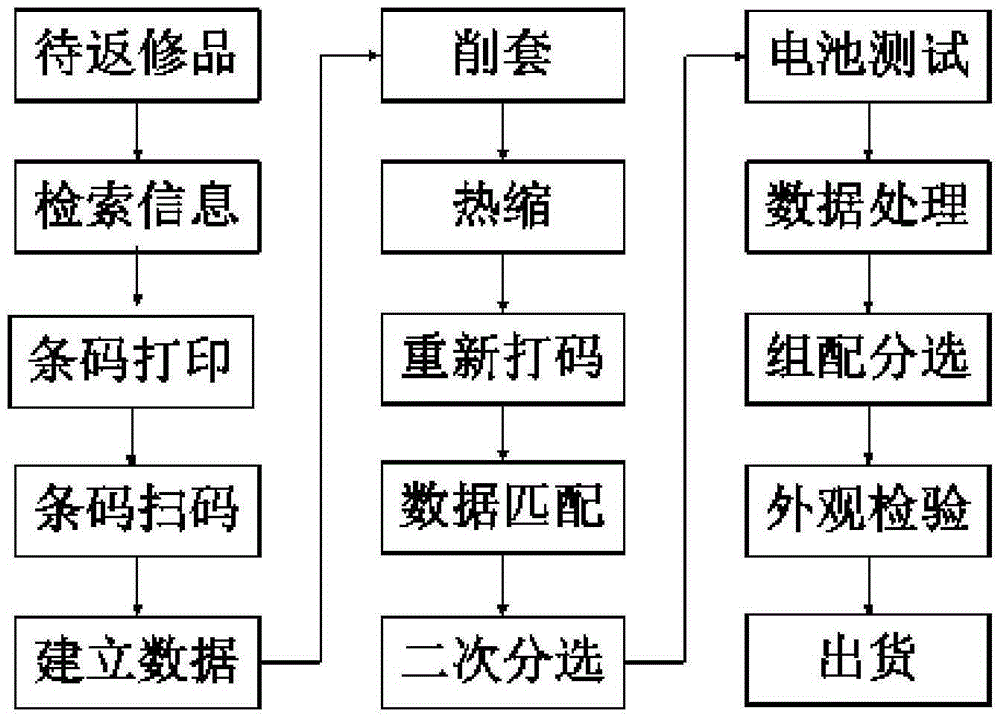

[0018] see Figure 1-2 As shown, a battery online rework operation processing method includes:

[0019] Retrieve the information of the battery to be repaired, print the initial barcode of the battery to be repaired and scan it into the database, and the corresponding relationship with the information of the battery to be repaired;

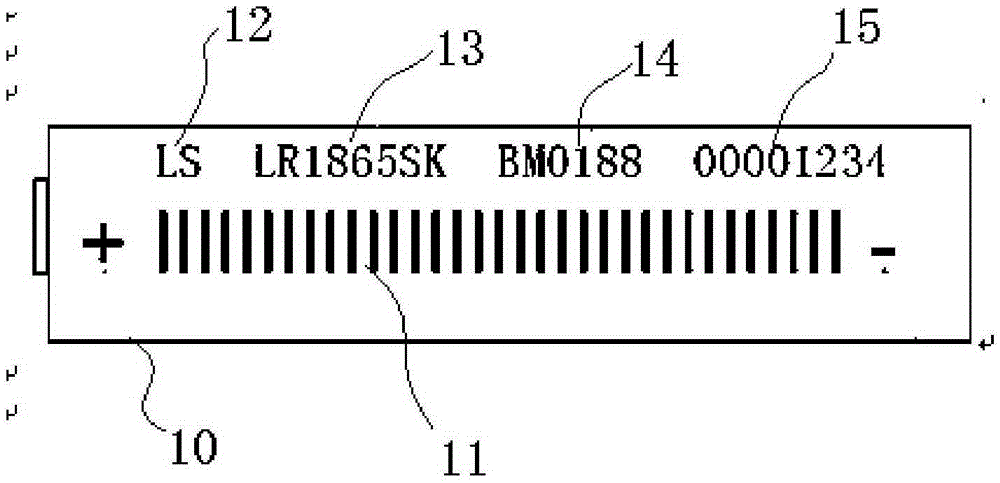

[0020] According to the new processing batch, the reworked battery should be peeled off and heat-shrinked, and the batch number of the battery will be re-established and the corresponding continuous barcode information from small to large will be printed, entered into the database, and pressed one by one in the database The corresponding relationship generates a secondary identification at the corresponding position in the original input informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com