Cleaning method of the reaction chamber

A reaction chamber and chamber technology, applied in the field of microelectronics, can solve the problems of inability to completely clean fluorocarbon etching by-products, poor cleaning effect of dry cleaning process, and reduce equipment operation rate, so as to improve equipment operation Efficiency, improved cleaning effect, and improved operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

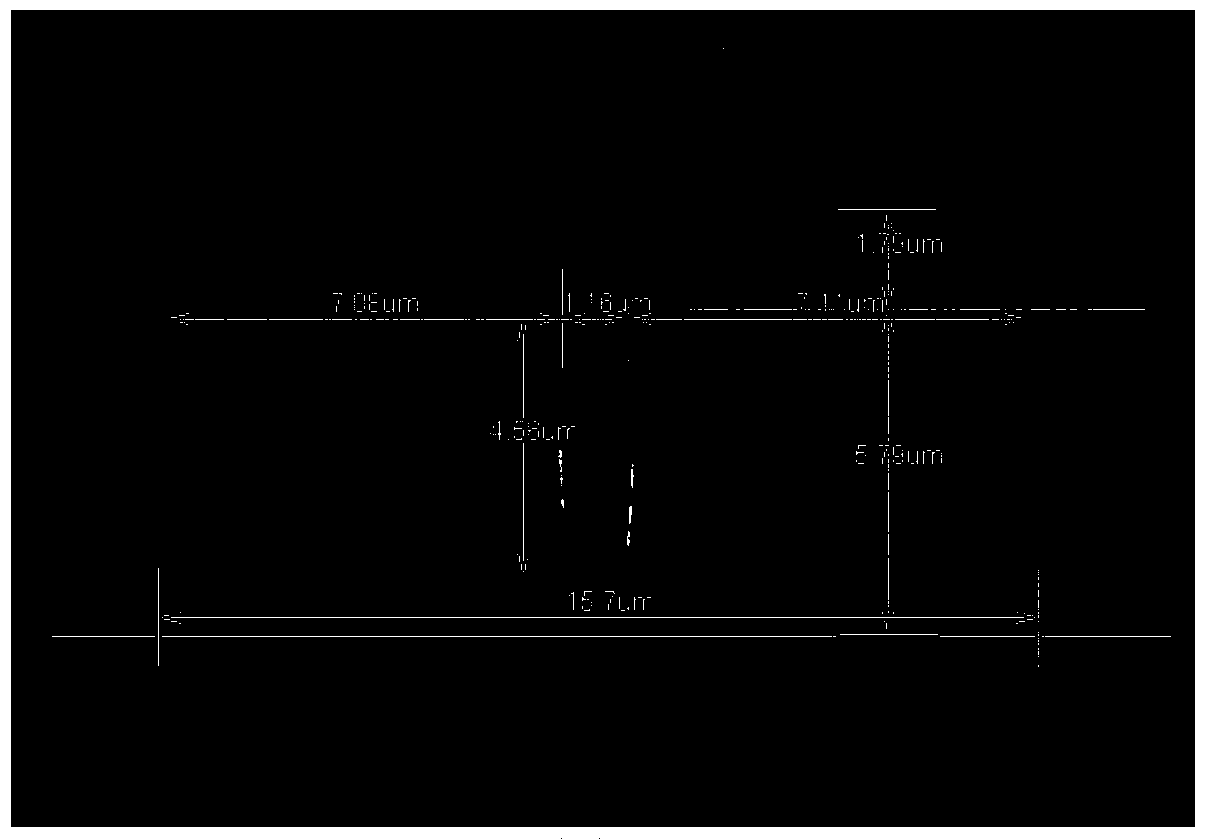

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the method for cleaning the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0033] The cleaning method of the reaction chamber provided by the invention comprises the following steps:

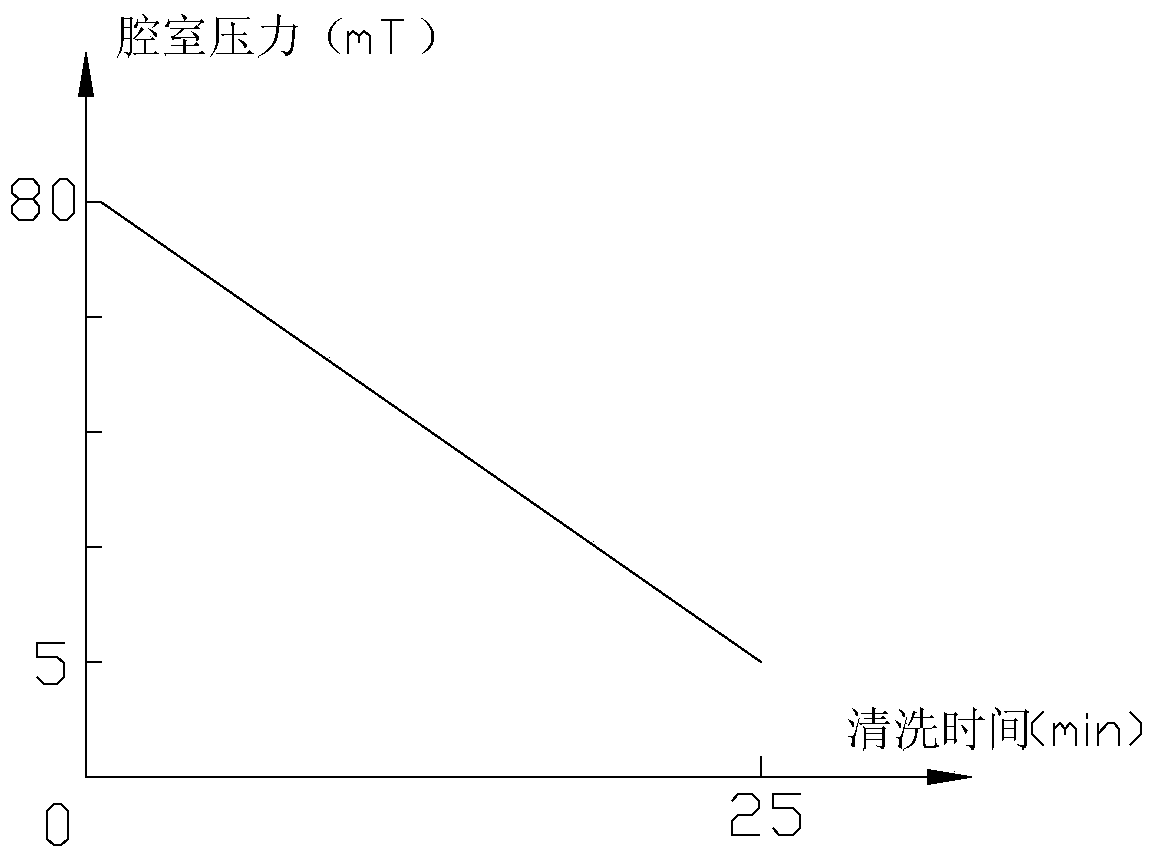

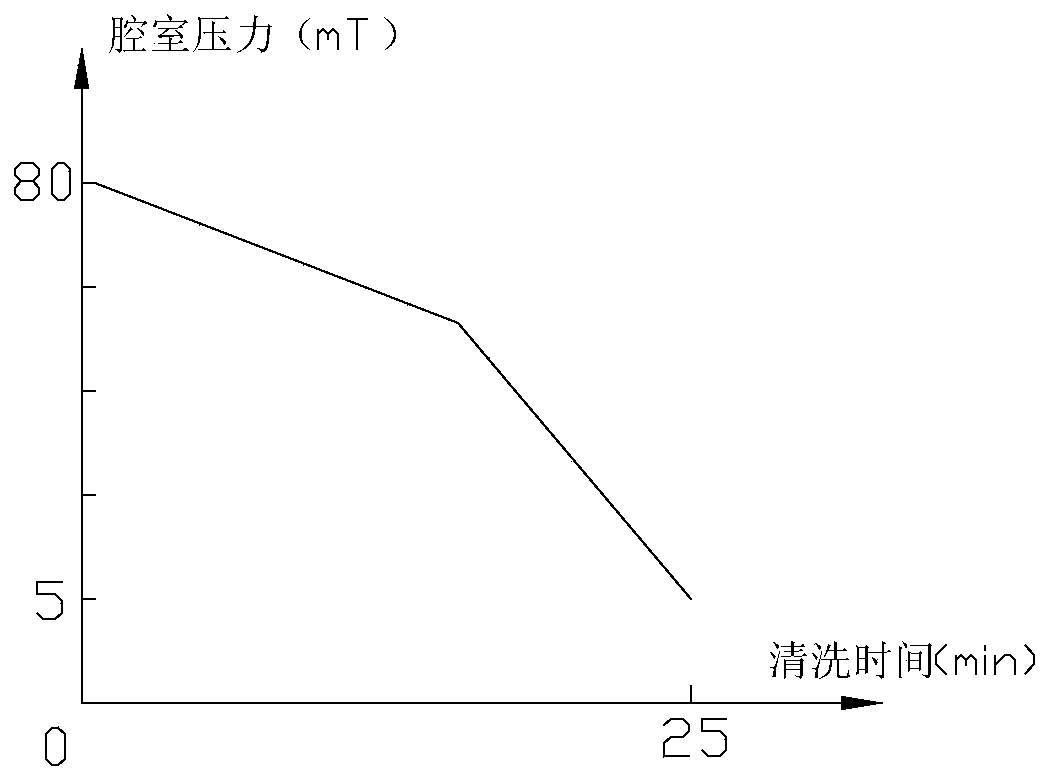

[0034] Perform dry cleaning on the reaction chamber, and adjust the chamber pressure of the reaction chamber according to predetermined rules as the cleaning time increases, so that it decreases from the preset highest pressure value to the lowest pressure value, or automatically The set minimum pressure value rises to the maximum pressure value.

[0035] Among them, the process of dry cleaning is as follows: the cleaning gas is introduced into the reaction chamber, and the power supply of the upper electrode is turned on at the same time, so as to apply the power of the upper electrode to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com