System and method for sealing glass packaging body through laser scanning

A technology of laser scanning and sealing glass, which is used in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

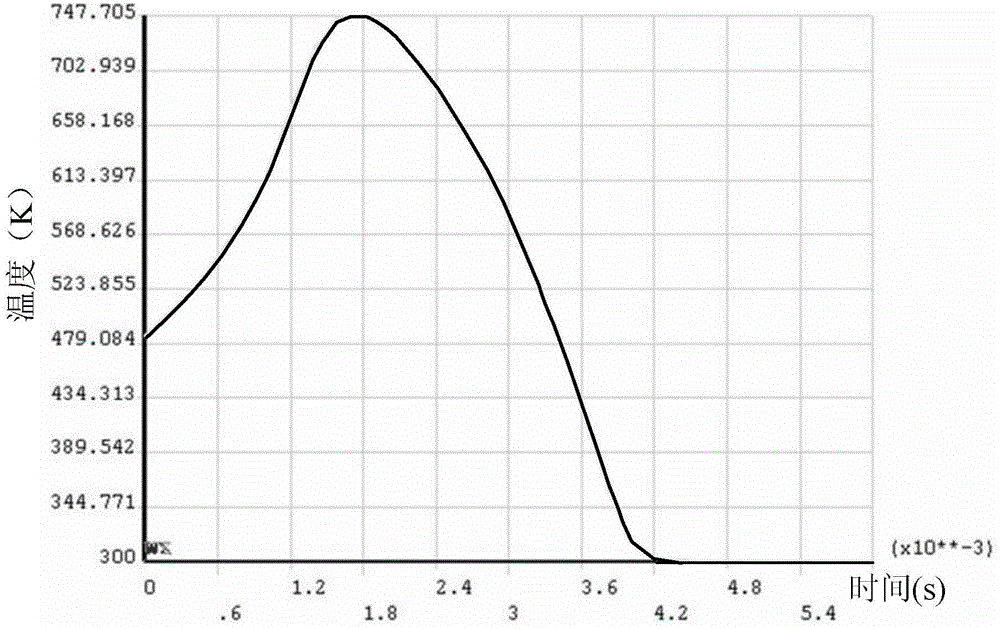

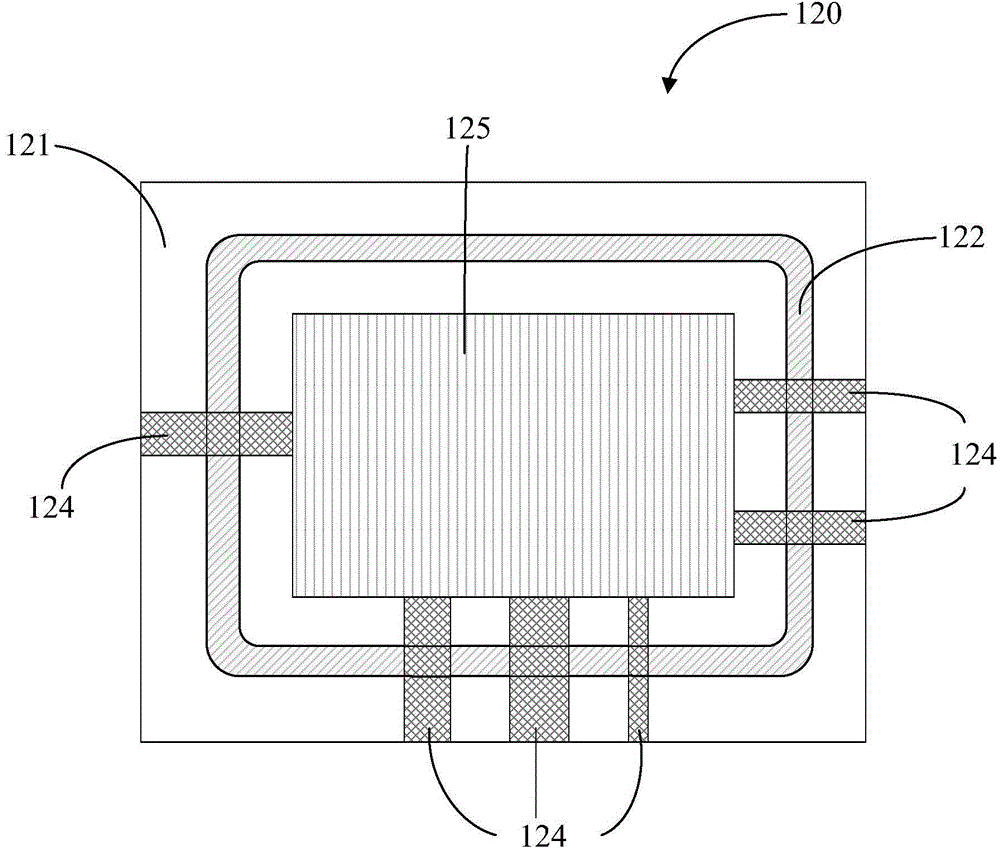

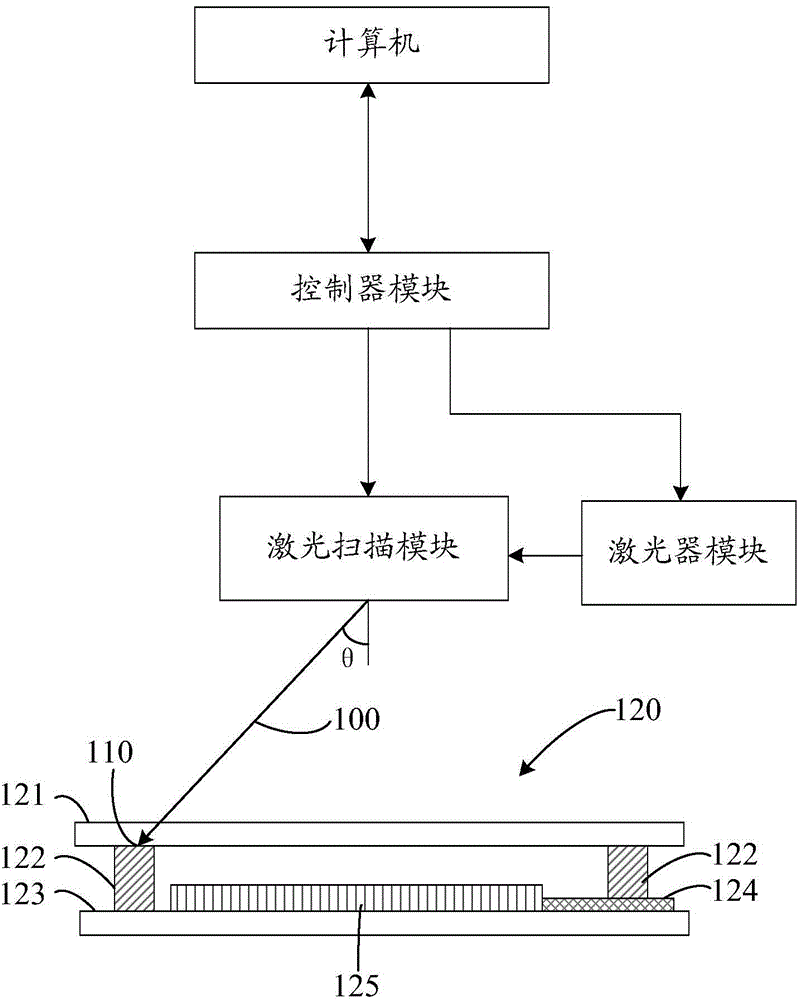

[0051] Please refer to figure 2 and image 3 , in this embodiment, a laser scanning sealing glass package system is proposed, which is used to form a hermetic seal on the OLED display 120 using glass frit, wherein the OLED display 120 is a typical glass package, and the OLED The main structure of the display 120 includes a cover glass 121 , a glass frit 122 , a substrate glass 123 , an OLED layer 125 and an electrode 124 . Wherein, the glass frit 122 is located on the substrate glass 123 of the OLED display 120, and its cross-sectional view is shown in image 3 As shown in the top view as figure 2 shown. The glass frit 122 is pre-cured on the substrate glass 123 through screen printing and pre-sintering steps to form a rounded rectangular sealing line with a certain thickness. The OLED layer 125 on the substrate glass 123 is located inside the sealing line of the glass frit 122 , and there are electrodes 124 on the substrate glass 123 connecting the inside and outside of...

Embodiment 2

[0067] Please refer to Figure 8 , in this embodiment, the proposed laser scanning sealing glass package system has more temperature measurement modules than in Embodiment 1, and the temperature measurement module is connected to the controller module for measuring the laser irradiation to the glass frit. The real-time temperature of the light spot on the surface is fed back to the controller module. The temperature measurement module can measure the temperature of the glass frit 122 at the position of the light spot 110 in a non-contact and real-time manner, and feed it back to the controller module. One feature is that when the light spot 110 moves at a high speed, the temperature measurement The module can still have sufficient temporal / spatial resolution to measure the temperature of the frit 122 where the spot 110 is located. The controller module can collect and process the temperature signal fed back by the temperature measurement module, and form a closed-loop control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com