Quasi-synchronous laser packaging system and method

A laser encapsulation, quasi-synchronized technology, applied in electrode system manufacturing, discharge tube/lamp manufacturing, electrical components, etc., can solve problems such as uneven temperature field distribution, improve temperature uniformity, uniform heating, and achieve precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

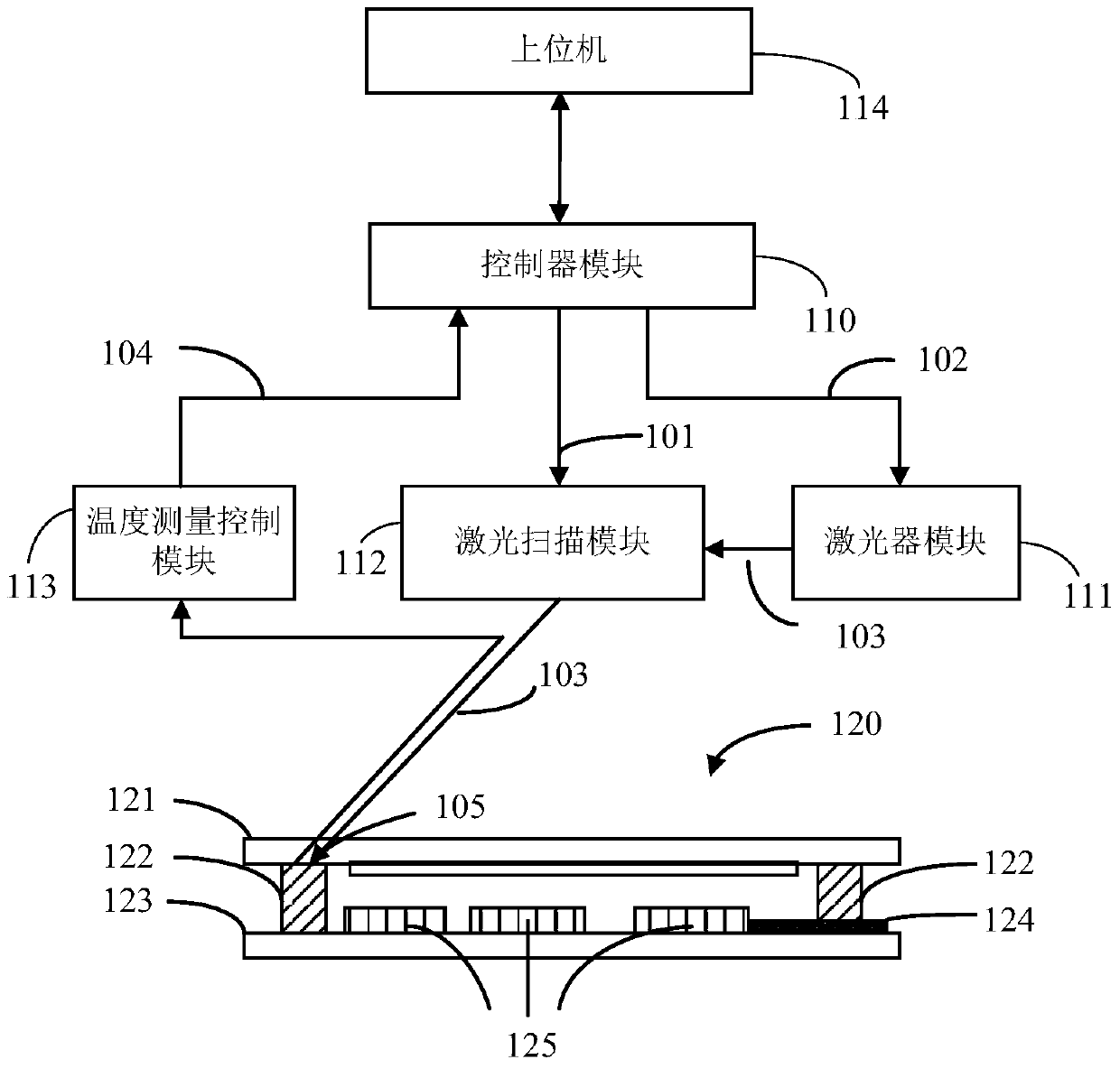

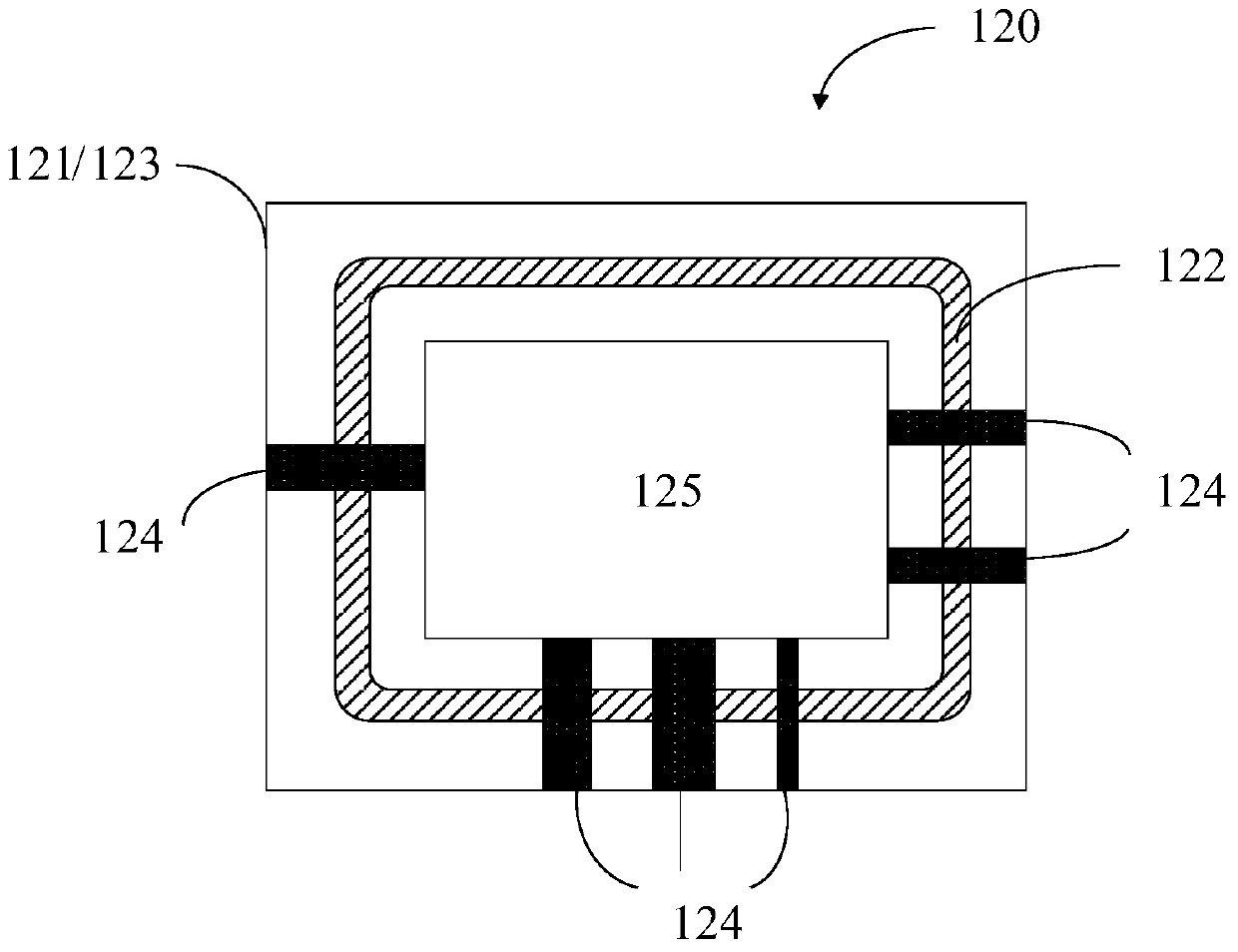

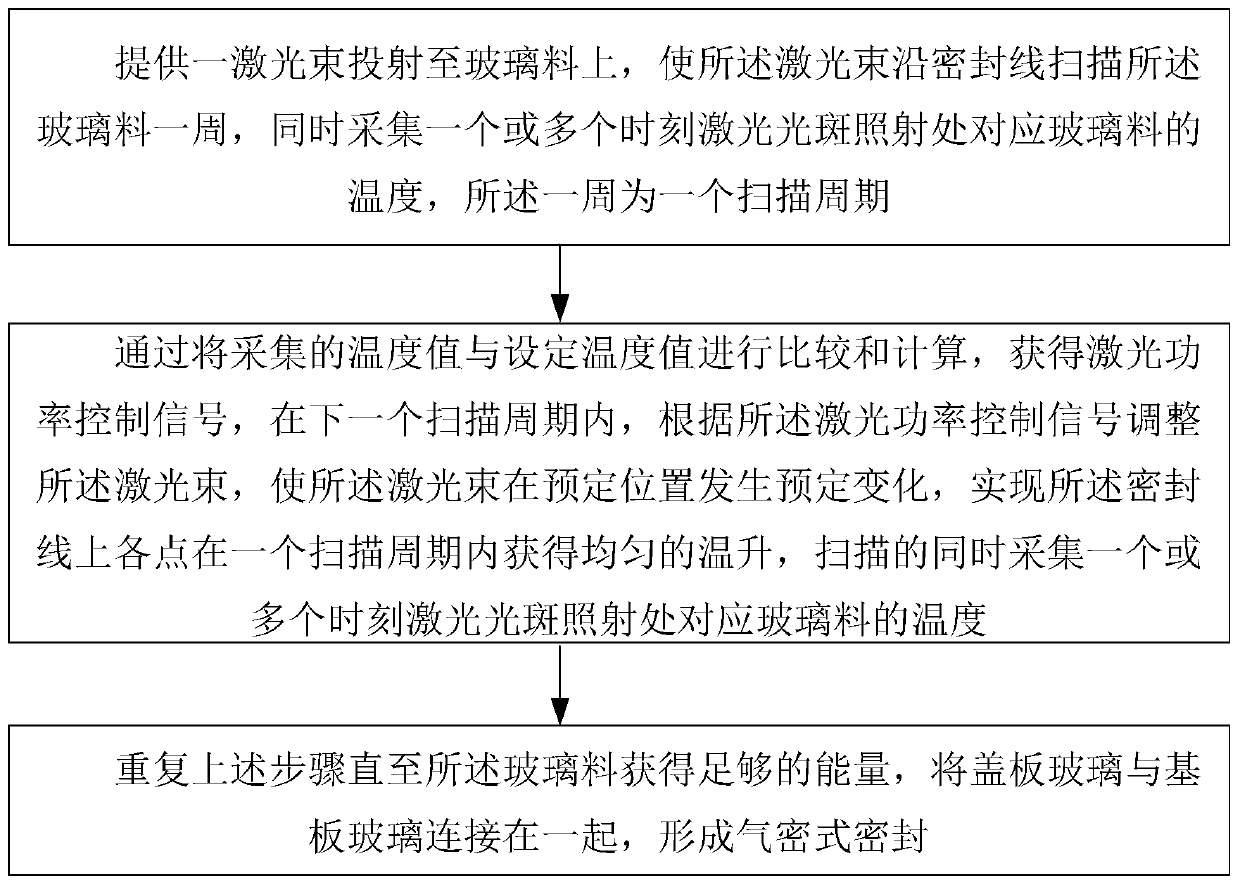

[0055] Please refer to figure 1 , which is a schematic structural diagram of the quasi-synchronous laser packaging system provided by Embodiment 1 of the present invention. The quasi-synchronous laser packaging system is used to seal glass packages, such as figure 1 As shown, the quasi-synchronous laser packaging system includes: a controller module 110, a laser module 111, a laser scanning module 112, a temperature measurement control module 113, and a host computer 114; wherein the laser module 111 is used to emit a laser beam 103 and transmitted to the laser scanning module 112; the laser scanning module 112 is used to project the laser beam 103 on the frit 122, and scan the frit along the sealing line; the temperature measurement control module 113 is used to measure The temperature of the glass frit 122 corresponding to the irradiation place of the laser spot at one or more times, outputting the laser power control signal 104 to the controller module 110; the controller ...

Embodiment 2

[0077] On the basis of the first embodiment, this embodiment provides a more specific quasi-synchronous laser packaging system and method.

[0078] Please refer to Figure 4 , which is a schematic structural diagram of the quasi-synchronous laser packaging system provided by Embodiment 2 of the present invention. Such as Figure 4 As shown, the quasi-synchronous laser packaging system includes: a scanning controller 10 , a laser 11 , a pyrometer 12 , a pyrometer controller 13 , a scanning vibrating mirror 14 and a computer (PC) 15 . Wherein, the scanning controller 10, the laser 11, the pyrometer 12, the pyrometer controller 13, the scanning vibrating mirror 14, and the computer (PC) 15 are respectively equivalent to the controller module, the laser module, and the temperature measurement module described in Embodiment 1. The sub-concepts of the control module, the laser scanning module and the host computer 114. The laser 11 is connected to the scanning galvanometer 14 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com