Processing method of stainless steel positive electrode cap for zinc-manganese battery

A zinc-manganese battery and processing method technology, applied in battery pack parts, battery boxes/jackets, small-sized batteries/battery packs, etc. Quality, solution to high price effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

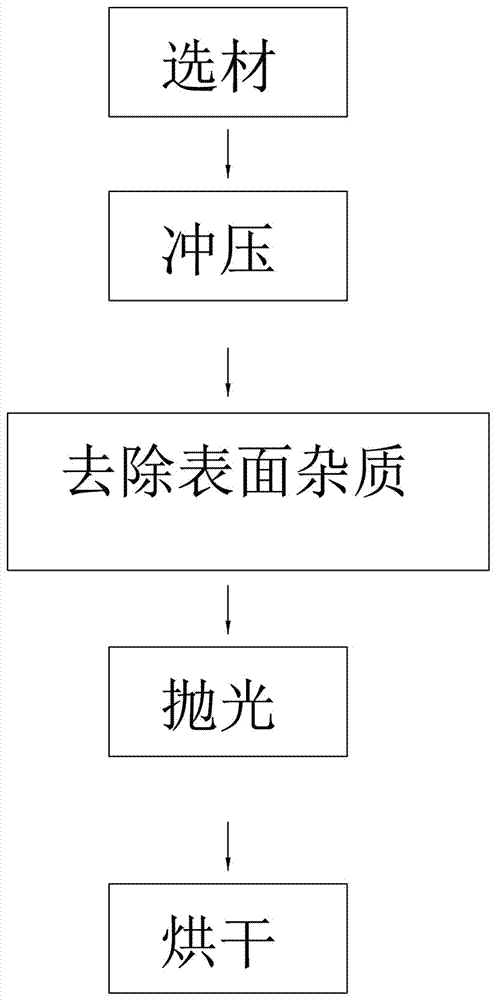

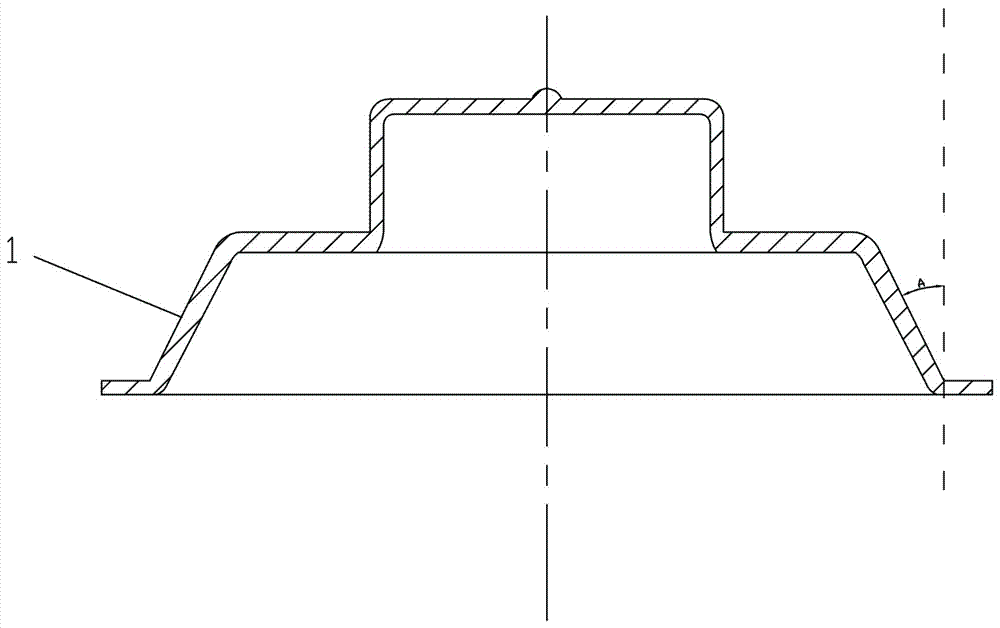

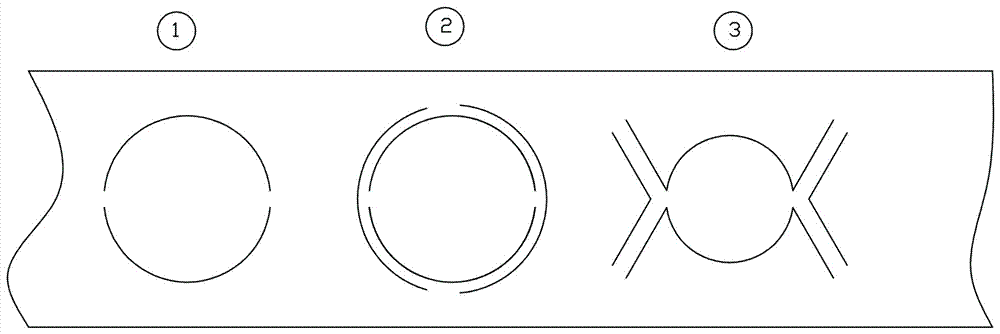

[0023] like figure 1 , 2 Shown in and 3, the processing method of the zinc-manganese battery stainless steel positive electrode cap of the present invention is characterized in that the steps are as follows: (1) material selection, select austenitic stainless steel strip, thickness≦0.15mm; because the austenitic stainless steel strip is stamped into After the surface treatment of the product, the product will show a bright white luster and a beautiful appearance, which is very close to the color of the electroplated part, so that it can be more acceptable to customers, and the cost of surface treatment is not high. (2) Stamping, A. Pre-cut the stainless steel strip twice, cut out two semi-circular arcs each time, a total of four semi-circular arcs, and leave about 1mm uncut between the two semi-circular arcs; B. A semi-arc circle is used to stamp and form the positive electrode cap of the battery; this fully pre-cut design can achieve better stretching effect and the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com