Tissue repair scaffold and preparation method and use thereof

A tissue repair and composite fiber technology, applied in tissue regeneration, prosthesis, surgery, etc., can solve the problems of difficult tissue compliance and adhesion, strong immune rejection, difficult cells, etc. The effect of speeding up repair and promoting cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0050] In this embodiment, the tissue repair scaffold comprises at least one surface of a composite fiber layer comprising composite fibers composed of an adhesion factor and a hydrophobic synthetic material. The tissue repair scaffold may consist of only one composite fiber layer, and in this case, the tissue repair scaffold is essentially a "composite fiber membrane". When the prepared "composite fiber membrane" is used as one layer of the tissue repair scaffold, it is called "composite fiber layer". Therefore, it should be understood that in this application, "composite fiber membrane" and "composite fiber layer" are only different in name, they have the same structural composition, and both include composite fibers composed of adhesion factors and hydrophobic synthetic materials.

[0051]

[0052] The composite fiber layer of the present invention includes composite fibers composed of an adhesive factor and a hydrophobic material.

[0053] The adhesion factor of the pre...

no. 2 approach

[0074]In this embodiment, the tissue repair scaffold has a porous three-dimensional network structure formed by a composite fiber layer and a hydrophilic material; the composite fiber layer contains composite fibers composed of an adhesion factor and a hydrophobic synthetic material. The composite fiber layer described therein is the same as that of the first embodiment described above.

[0075]

[0076] In this embodiment, the tissue repair scaffold has a porous three-dimensional network structure formed by a composite fiber layer and a hydrophilic material, and the porous three-dimensional network structure is formed on the surface and / or inside the surface of the composite fiber layer.

[0077] The porous three-dimensional network structure can be formed by immersing the prepared composite fiber layer (membrane) in a solution of a hydrophilic material, taking it out and performing freeze-drying.

[0078] The hydrophilic material used to form a porous three-dimensional net...

Embodiment 1

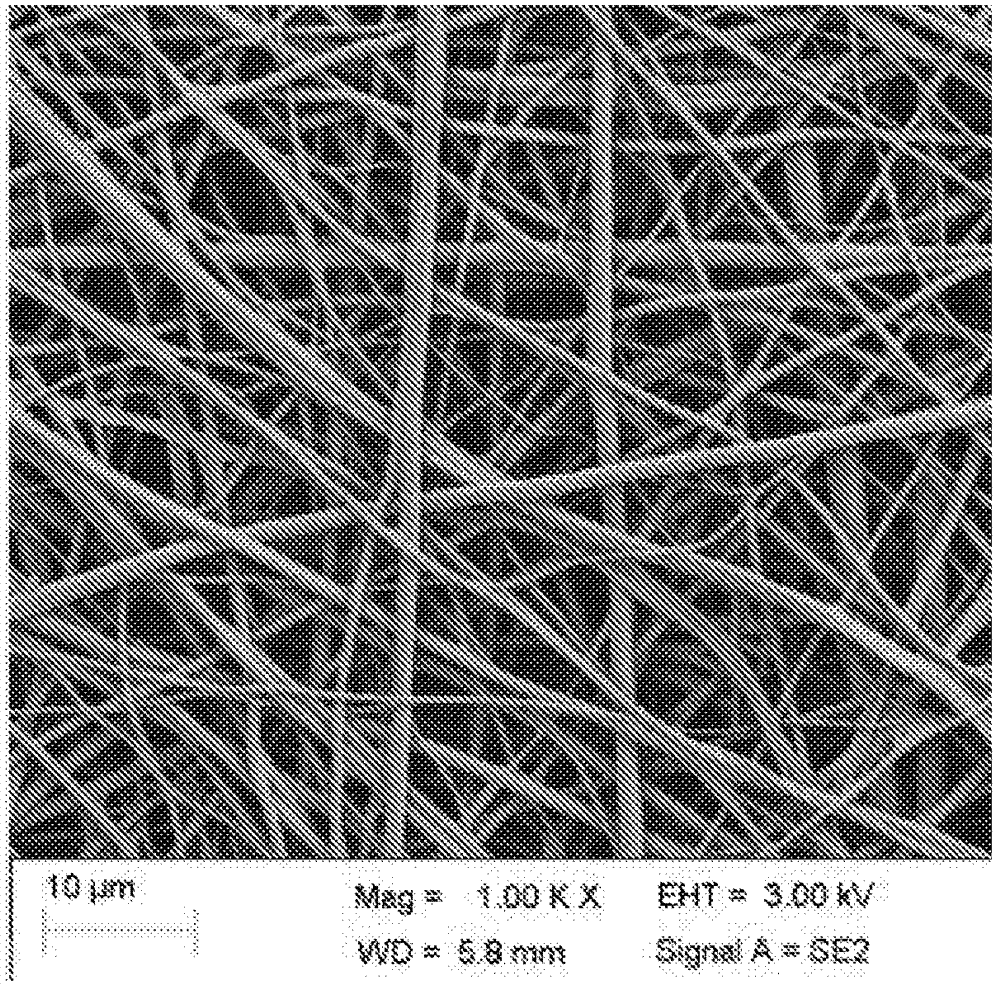

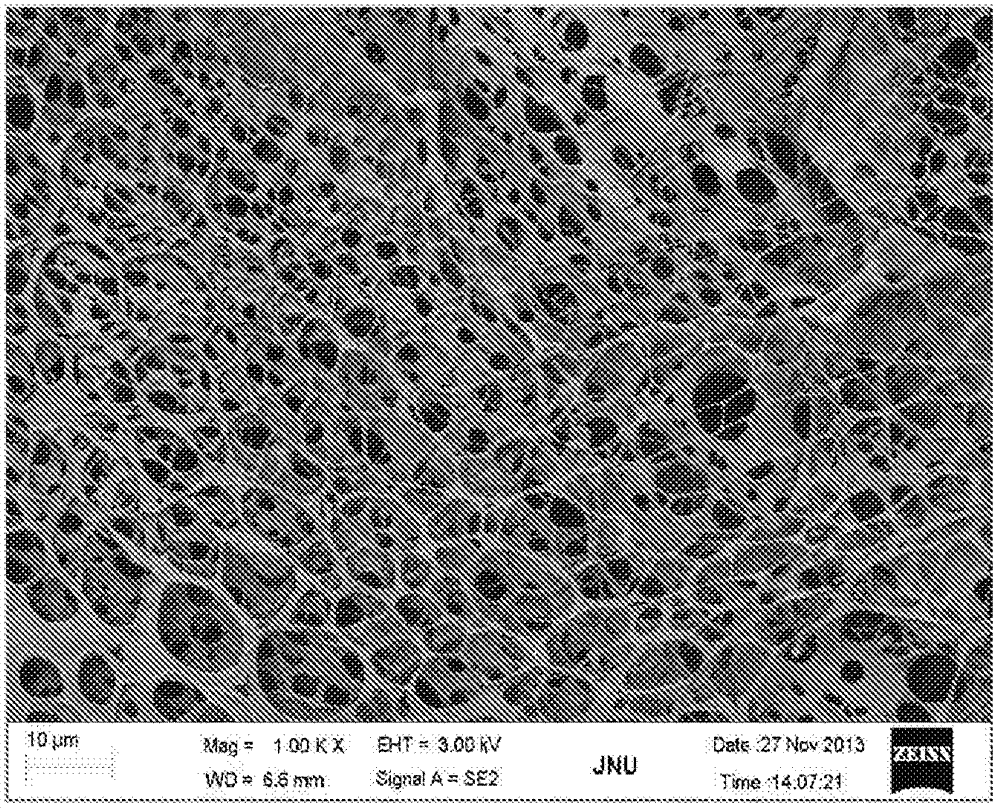

[0093] Dissolve PCL and gelatin in trifluoroethanol according to the mass ratio of 10:1 to form a solution, and then the solution enters the centrifugal spinning machine through the propulsion pump, the propulsion speed of the propulsion pump is 150g / min, the linear velocity of the centrifugal disc is 6000m / min, the solution The fiber is spun rapidly, and the spinning temperature is 50°C. After the spinning is finished, the membrane is removed from the receiver, and the solvent is removed by vacuum drying to obtain a composite fiber membrane.

[0094] The SEM image of the composite fiber is shown in figure 1 -A, after the composite fiber is treated in 50°C water that can dissolve gelatin but not PCL, its SEM image is shown in figure 1 -B, it can be clearly seen that the composite fiber has a composite structure of PCL and gelatin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com