Three dimensional printing

A 3D printer, fiber technology, applied in 3D printing. field, which can solve problems such as parts not being durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

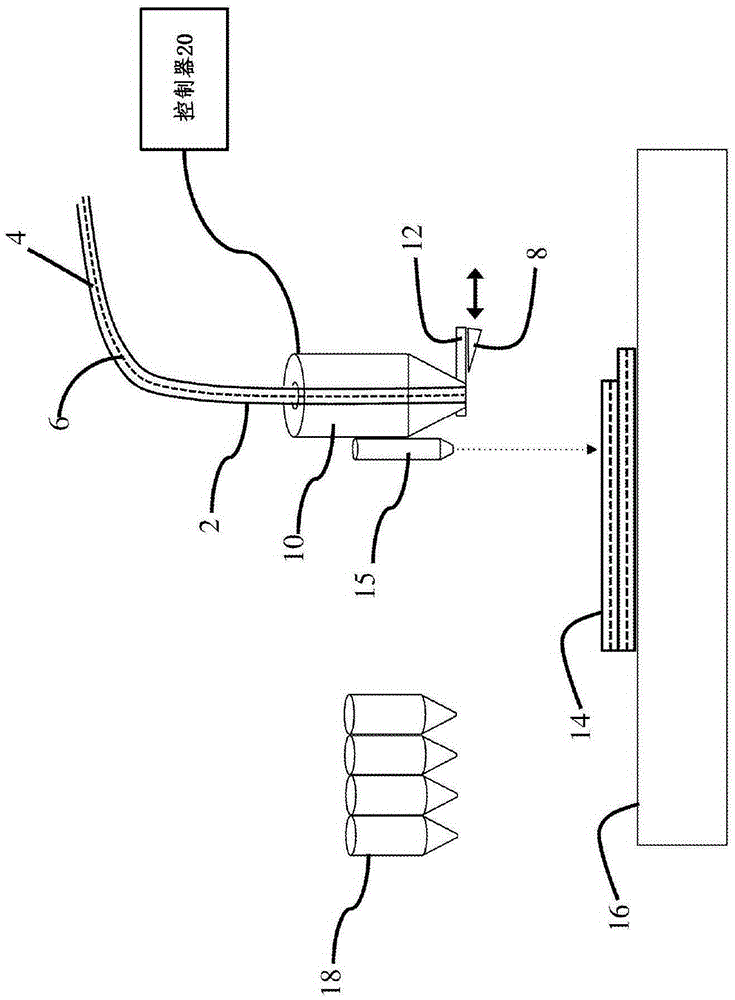

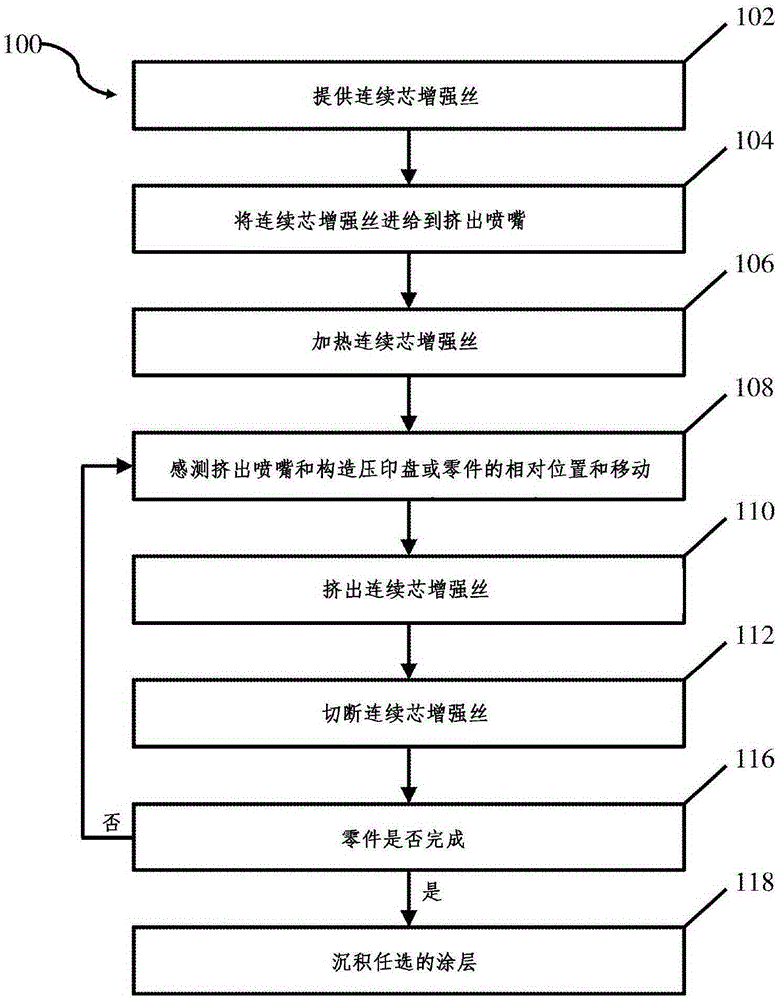

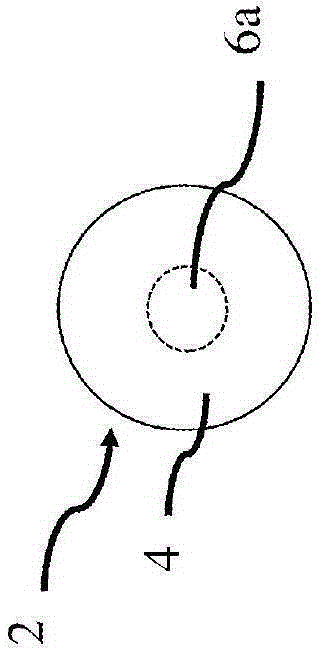

Embodiment Construction

[0124] The inventors have recognized that one of the basic limitations associated with the usual additive manufacturing methods is the strength and durability of the resulting parts. For example, fuse manufacturing results in parts exhibiting lower strength than comparable injection molded parts. Although not wishing to be bound by theory, the decrease in strength is due to weaker bonds (also bubbles and voids) between adjacent strips of deposited material compared to continuous and substantially void-free materials formed in, for example, injection molding. The inventor also recognized that the prepreg composite construction method using sheet-based technology to form three-dimensional parts is time-consuming and difficult to handle, resulting in high costs. In addition, bending such sheets around a curve, such as a circle, may cause fiber overlap, snapping, and / or twisting, resulting in undesirable soft spots in the resulting part. As for the three-dimensional printer using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com