Xiaotangling capsules and preparing method thereof

A technology of Xiaotangling and capsule, applied in the field of Xiaotangling capsule and its preparation, can solve the problems of unsatisfactory curative effect, low curative effect, slow disintegration and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

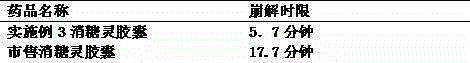

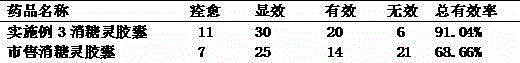

Examples

Embodiment 1

[0028] Take 192g of agarwood, 96g of poria cocos, 19.2g of hemp seed, 30g of coptis, 490g of trichosanthemi, 88g of Eucommia, 512g of astragalus, 180g of salvia miltiorrhiza, 128g of medlar, 160g of sarcocarpus, crush them into 60 mesh coarse powder, and extract them by carbon dioxide supercritical extraction method , the extraction pressure is 24Mpa, the extraction temperature is 16°C, the separator pressure is 11Mpa, the separator temperature is 42°C, the separation time is 1.7 hours, the carbon dioxide flow rate is 26L per hour, and the extract is obtained; the extract is dried under reduced pressure at 62°C to obtain a dry paste; Add 150g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder, 45g of microcrystalline cellulose, 45g of cross-linked polyvinylpyrrolidone, and cross-linked carboxymethyl fiber Sodium plain 35g, mixed evenly, wet granulat...

specific Embodiment 2

[0030] Take 192g of agarwood, 96g of poria cocos, 19.2g of hemp seed, 30g of coptis, 490g of trichosanthemi, 88g of Eucommia, 512g of astragalus, 180g of salvia miltiorrhiza, 128g of medlar, 160g of sarcocarpus, crush them into 60 mesh coarse powder, and extract them by carbon dioxide supercritical extraction method , the extraction pressure is 35Mpa, the extraction temperature is 43°C, the separator pressure is 19Mpa, the separator temperature is 58°C, the separation time is 3.3 hours, the carbon dioxide flow rate is 33L per hour, and the extract is obtained; the extract is dried under reduced pressure at 78°C to obtain a dry paste; Add 200g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder, 55g of microcrystalline cellulose, 55g of cross-linked polyvinylpyrrolidone, and cross-linked carboxymethyl fiber Sodium plain 45g, mixed evenly, wet granulat...

Embodiment 3

[0032] Take 192g of agarwood, 96g of poria cocos, 19.2g of hemp seed, 30g of coptis, 490g of trichosanthemi, 88g of Eucommia, 512g of astragalus, 180g of salvia miltiorrhiza, 128g of medlar, 160g of sarcocarpus, crush them into 60 mesh coarse powder, and extract them by carbon dioxide supercritical extraction method , the extraction pressure is 30Mpa, the extraction temperature is 30°C, the separator pressure is 15Mpa, the separator temperature is 50°C, the separation time is 2.5 hours, the carbon dioxide flow rate is 30L per hour, and the extract is obtained; the extract is dried under reduced pressure at 70°C to obtain a dry paste; Add 175g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder, 50g of microcrystalline cellulose, 50g of cross-linked polyvinylpyrrolidone, and cross-linked carboxymethyl fiber Sodium plain 40g, mix well, wet granulate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com