A flat high-precision dual-axis turntable for parts processing

A biaxial turntable and parts processing technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of poor quality stability, unsatisfactory, low processing efficiency, etc., to achieve convenient operation, strong practicability, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

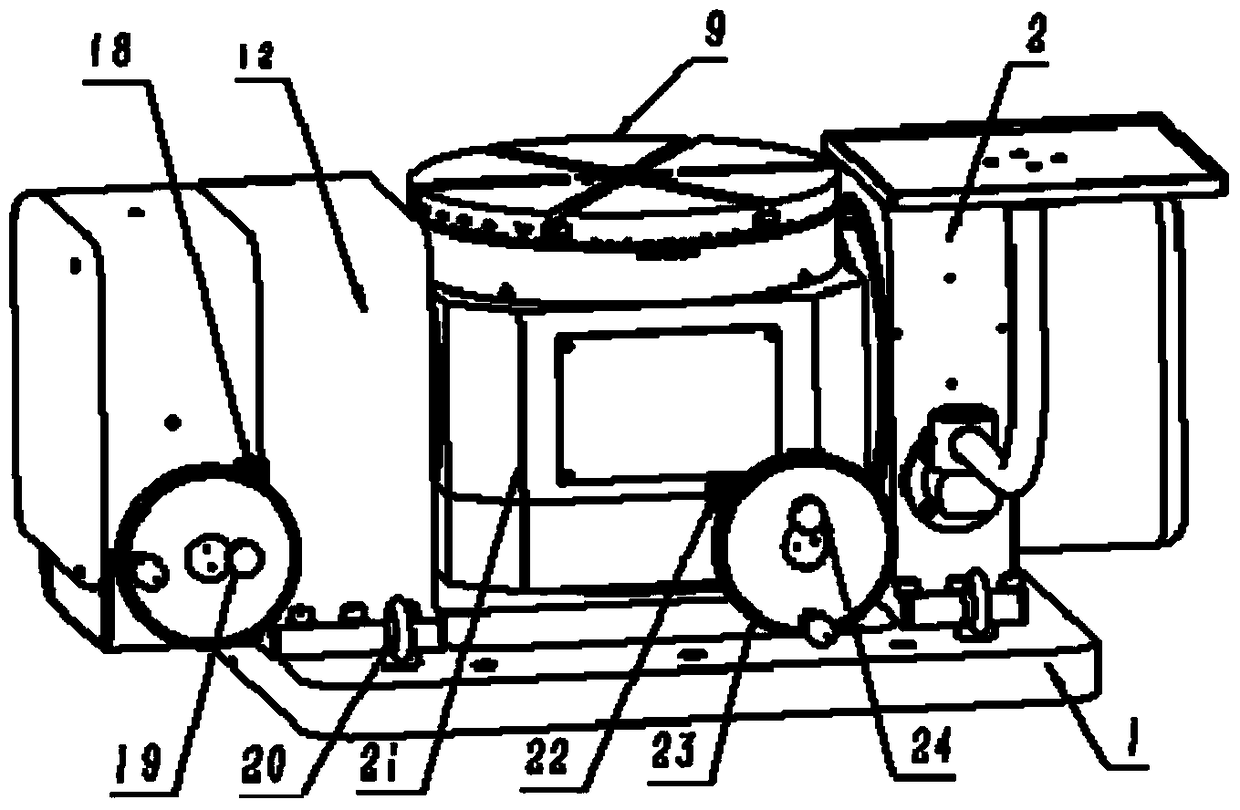

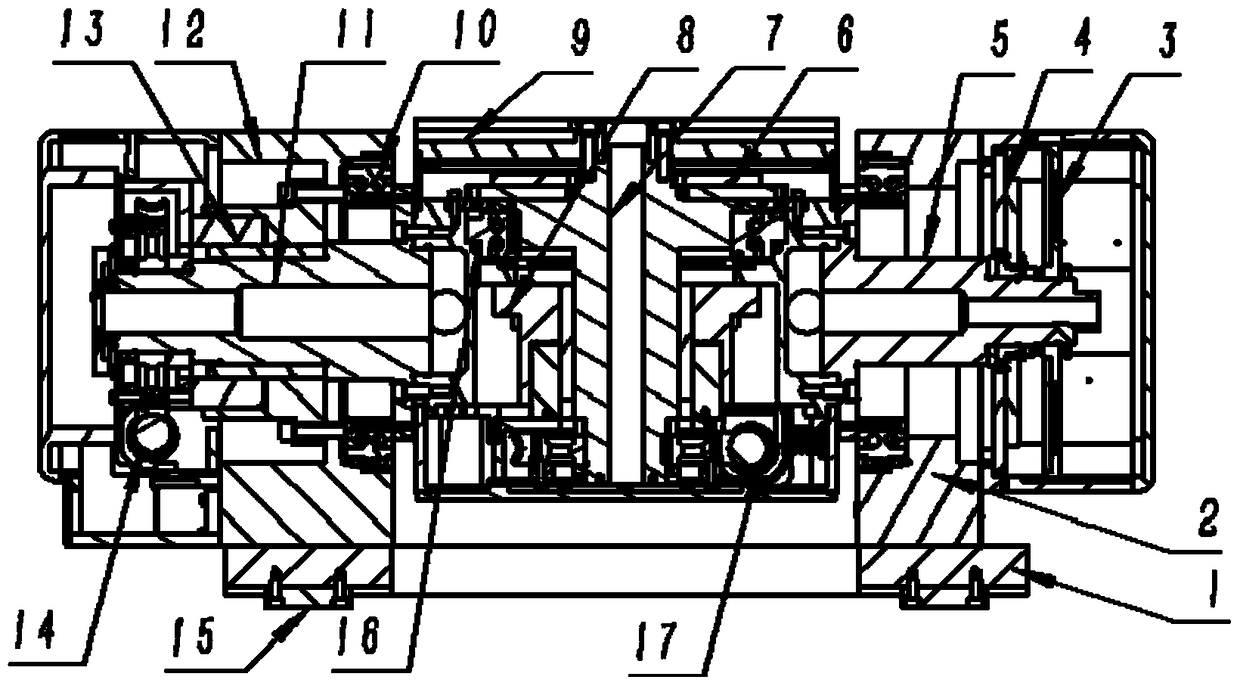

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0015] See attached Figure 1~2 As shown, this kind of flat high-precision dual-axis turntable for parts processing is characterized in that: the four corners of the upper surface of the rectangular annular base 1 are fixed with eyebolts 20, and the upper surface of the two short sides of the rectangular annular base 1 is fixed with left The ear seat 12 and the right ear seat 2 are fastened by hexagon socket head screws, the positioning block 15 with adjustable position is installed in the groove in the middle of the lower surface of the ring base 1, and the left ear seat 12 and the right ear seat 2 are those with through holes in the middle. Rectangular structure, the left pitch shaft 11 passes through the through hole of the thrust angular contact ball bearing 10, the flange of the left pitch shaft 11 is fastened to the inner ring of the thrust angular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com