Braking power generation mechanism based on hydraulic transmission

A technology of braking power generation and hydraulic transmission, which is applied in the direction of braking components, brakes, regenerative braking, etc., can solve the problems of recycling braking energy, waste of heat energy consumption, and insufficient effectiveness, so as to achieve reliable sealing and increase energy saving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

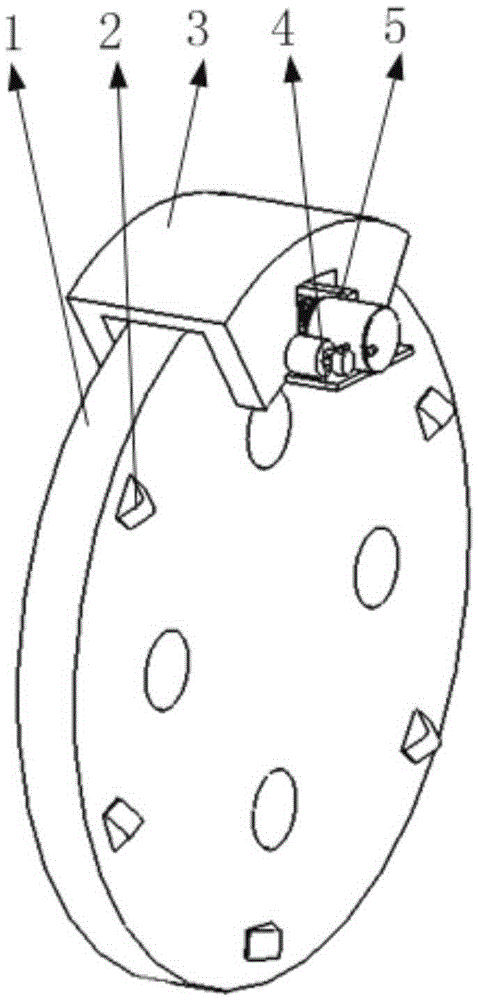

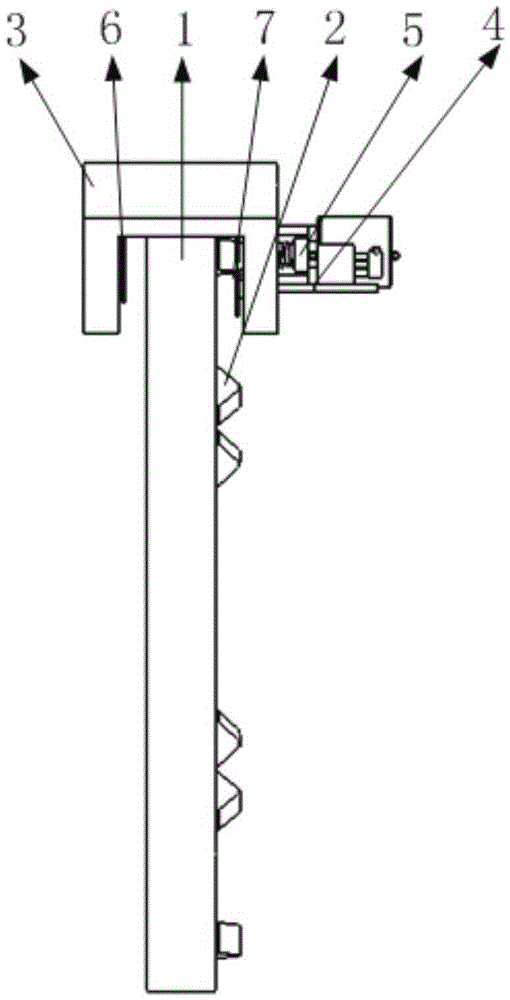

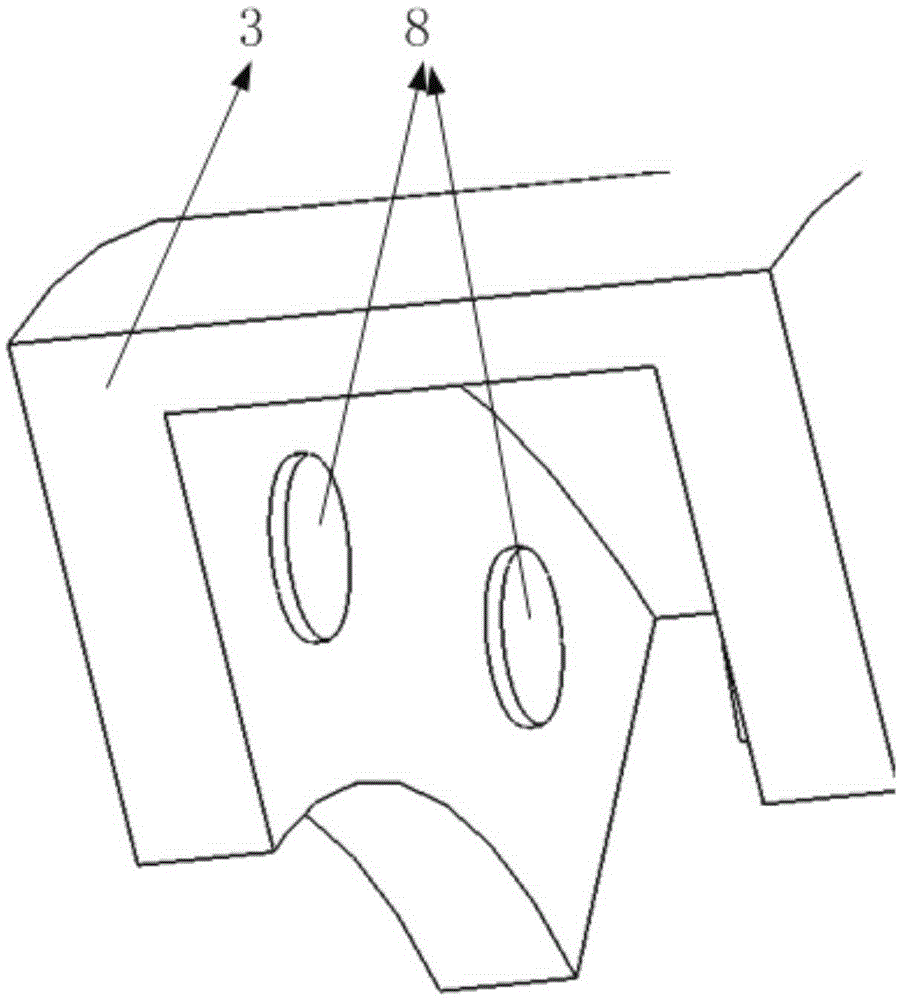

[0040] Such as figure 1 , 2 , 9, and 17, it includes brake disc, brake disc protrusion, brake mechanism support, first support plate, brake energy mechanical conversion mechanism, first brake pad bracket, second brake pad bracket, first brake hydraulic pressure Column, second brake hydraulic column, side rod transition rod, piston side rod, generator, hydraulic motor, hydraulic cylinder first inlet and outlet, hydraulic cylinder end cover, hydraulic cylinder, piston, second support plate, hydraulic motor support, Generator shaft, hydraulic motor first inlet and outlet, hydraulic motor second inlet and outlet, piston side rod groove, piston, hydraulic cylinder second inlet and outlet, among which figure 1 As shown, the brake disc protrusions are evenly installed on one side of the brake disc along the circumferential direction, and the brake mechanism is supported and installed on the axle. Supported in the U-shaped groove; such as figure 2 , 3 , 4, 5, and 6, the first bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com