Adjusting mechanism special for conveying belt of grain conveyor

An adjustment mechanism and conveyor technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of low work efficiency, frequent adjustment, and reduce the market share of conveyor equipment, so as to improve work efficiency, improve performance, and reduce downtime Effect of maintenance and debugging times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

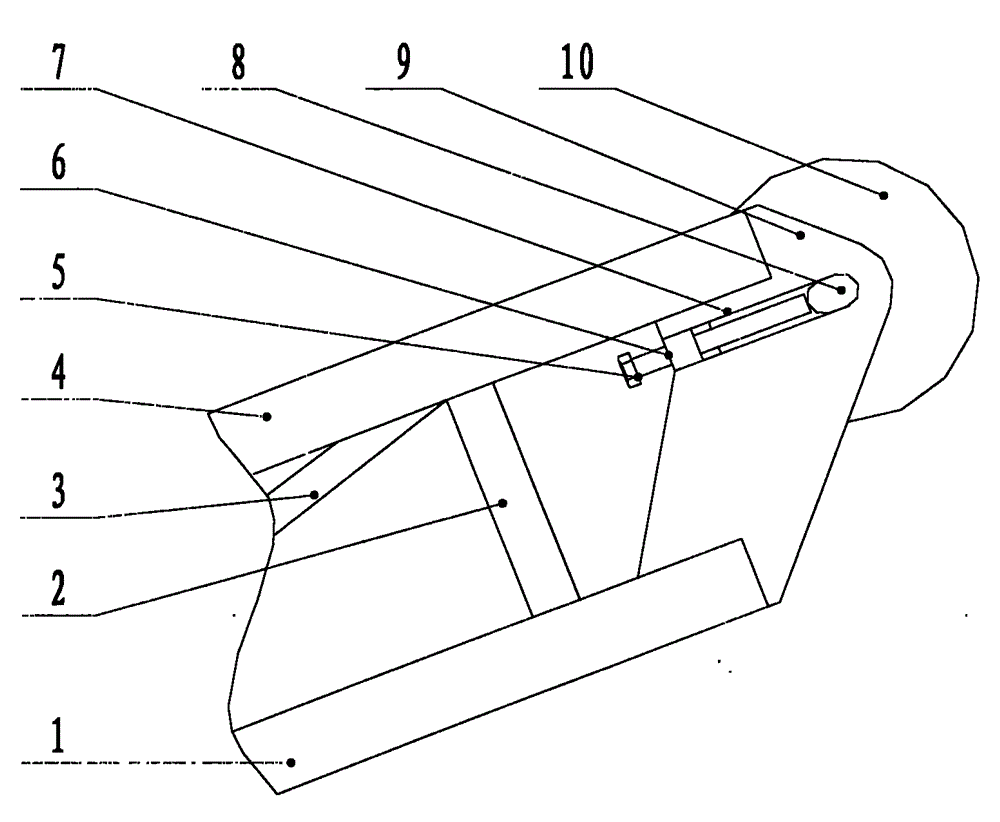

[0009] Products involved in the present invention such as figure 1 As shown, the conveying frame of the conveyor is welded by seamless steel pipes, and the upper main pipe 4 and the lower main pipe 1 are welded through the support pipe 2 and the cable-stayed pipe 3; 1 piece each; the upper main pipe 4 and the lower main pipe 1 are connected by welding. An adjustment slide groove 7 is provided in the middle of the bracket adjustment plate 9 , and an adjustment screw nut 6 is provided at the end of the adjustment slide groove 7 . Reversing roller 10 is arranged in the middle of conveying frame, is provided with reversing roller shaft 8 in the middle of reversing roller 10; The adjusting screw rod 5 provided on the female 6 makes the reversing roller shaft 8 move in the adjusting sliding groove 7; thus the effect of adjusting the tightness of the conveyor belt is achieved.

[0010] When installing the conveyor belt, first adjust the adjusting screw rod 5 to the shortest stroke,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com