Elevator monitoring method and elevator brake disc monitoring system

A monitoring system and brake disc technology, which is applied in the field of elevators and escalators, can solve problems such as incomplete sealing of brake discs, car slipping, and water film staining, and achieve the effects of easy real-time monitoring, simple calculation methods, and fast transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

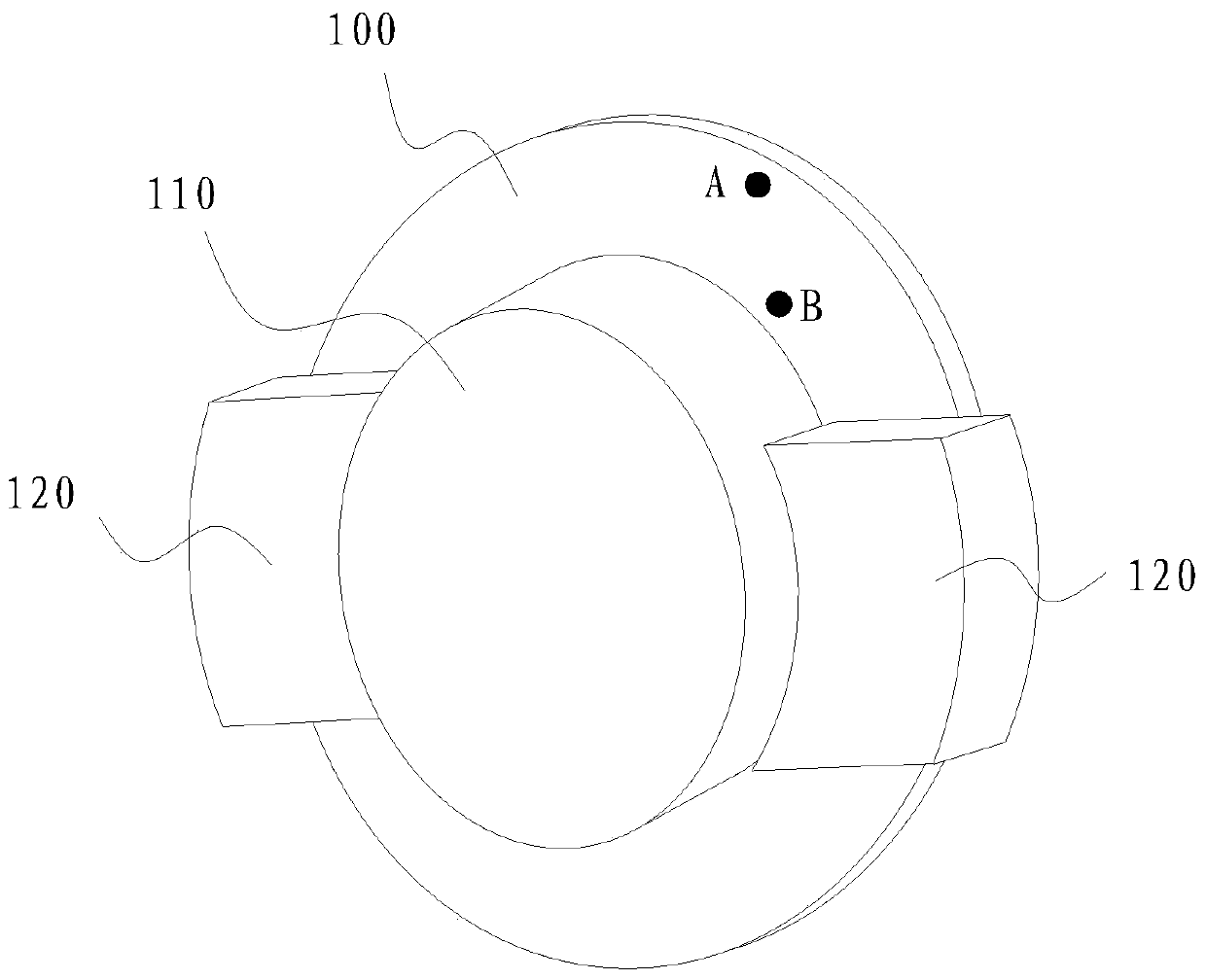

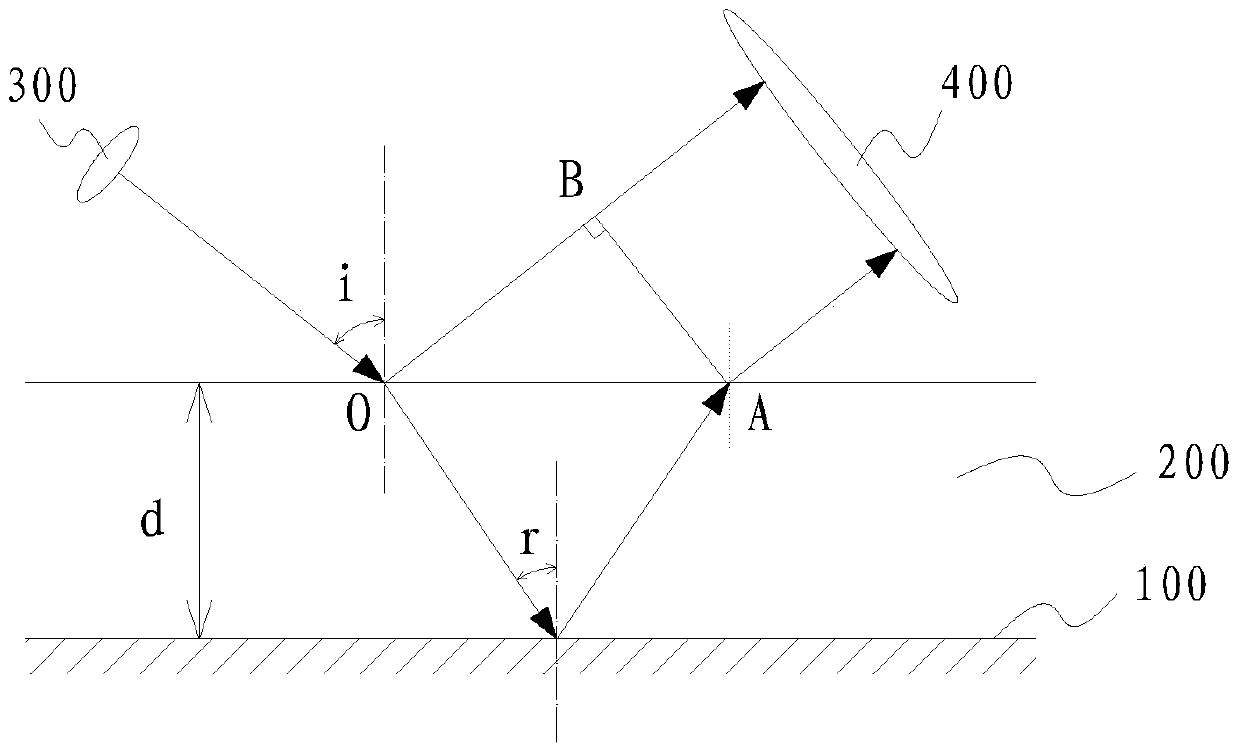

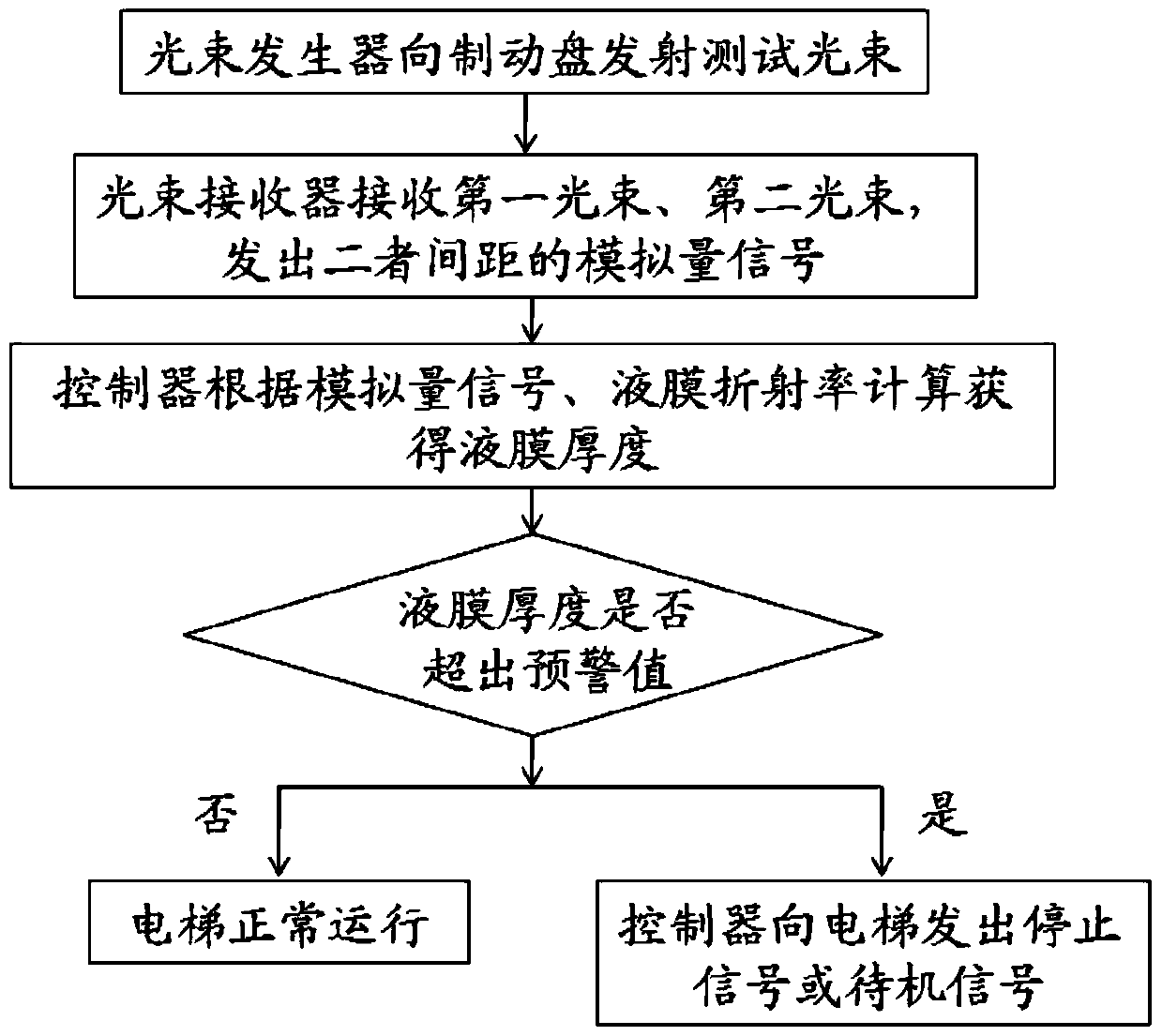

[0026] like figure 1 As shown, the brake disc 100 of the elevator main engine is in the shape of a ring, the center of the brake disc 100 is a rotating shaft 110 , and the brake parts 120 are arranged on both sides of the brake disc 100 . The elevator brake disc monitoring system is installed on the main machine of the elevator to monitor the thickness of the contaminated liquid film 200 on the main machine brake disc 100 in real time. When the thickness value of the liquid film 200 does not exceed the preset warning value, the elevator brake disc monitoring system will not Interfering with the normal operation of the elevator; when the thickness of the liquid film 200 exceeds the preset warning value, the elevator brake disc monitoring system sends a stop signal or a standby signal to the elevator, and the elevator stops running at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com