tp1 hoist disc brake shoe monitoring and adjustment device

A technology of adjusting device and disc brake, applied in the direction of mechanical equipment, brake type, etc., can solve the problems of poor system fault diagnosis ability, affecting troubleshooting and forecasting, and prolonging the impact of accidents, so as to improve stability and accuracy, save money The effect of manual measurement time and shortening of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

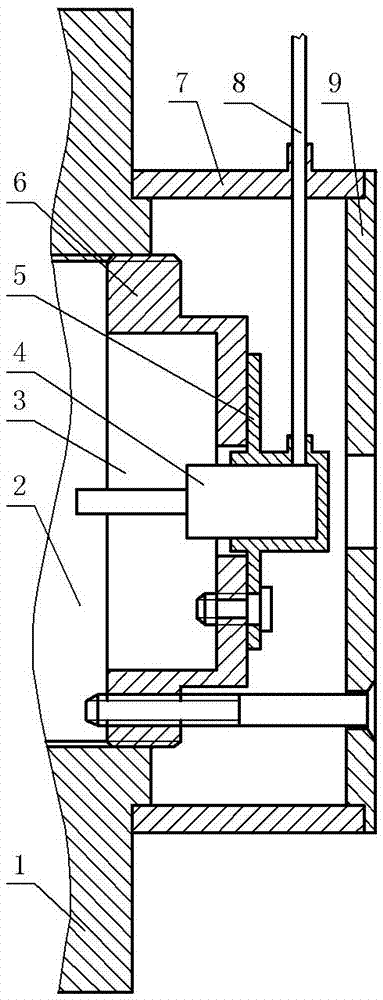

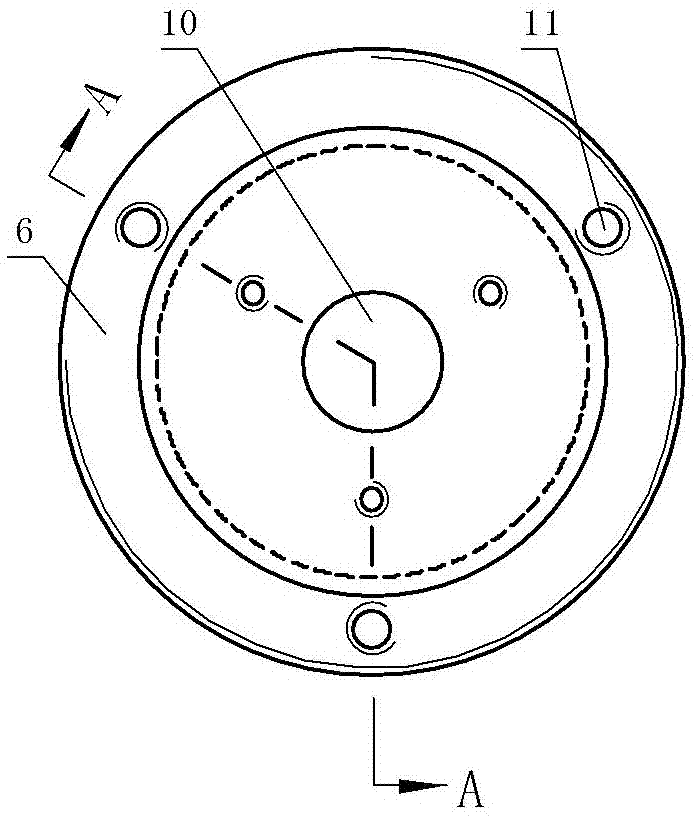

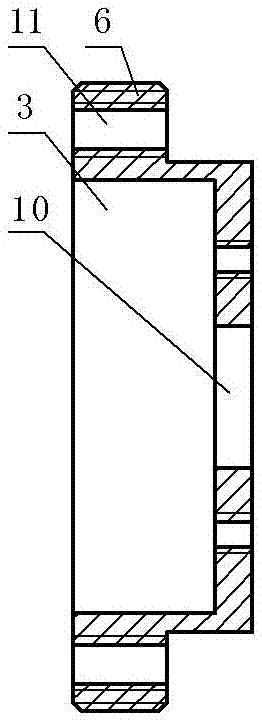

[0029] Example: see Figure 1-Figure 5 , in the figure, 1-disc gate cover, 2-center threaded hole, 3-inner cavity, 4-displacement sensor, 5-housing, 6-chassis, 7-fixing cylinder, 8-signal line, 9-end Cover, 10-chassis center hole, 11-threaded hole, 12-end cover center hole.

[0030] The TP1 type hoist disc brake shoe monitoring and adjusting device includes a chassis 6 and an end cover 9, wherein: the chassis 6 is cylindrical, and its outer surface is provided with threads, and its axis is provided with a chassis center hole 10, and the chassis 6 Through the screw thread on the outer circular surface and the central threaded hole of the disc gate end cover 1, a displacement sensor 4 is arranged on the outer end surface of the chassis 6, and the inner end of the displacement sensor 4 extends into the central hole 10 of the chassis, and the chassis 6 The outer end surface of the valve is connected with the end cover 9 through connecting bolts, and a fixed cylinder 7 is clamped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com