Drying device for glass cleaning machine

A glass cleaning and drying device technology, which is applied in the direction of drying gas arrangement, drying solid materials, and combination of methods to dry solid materials, etc., can solve the problems of large air resistance, complex structure, high cost, etc., achieve high degree of automation and improve work efficiency , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

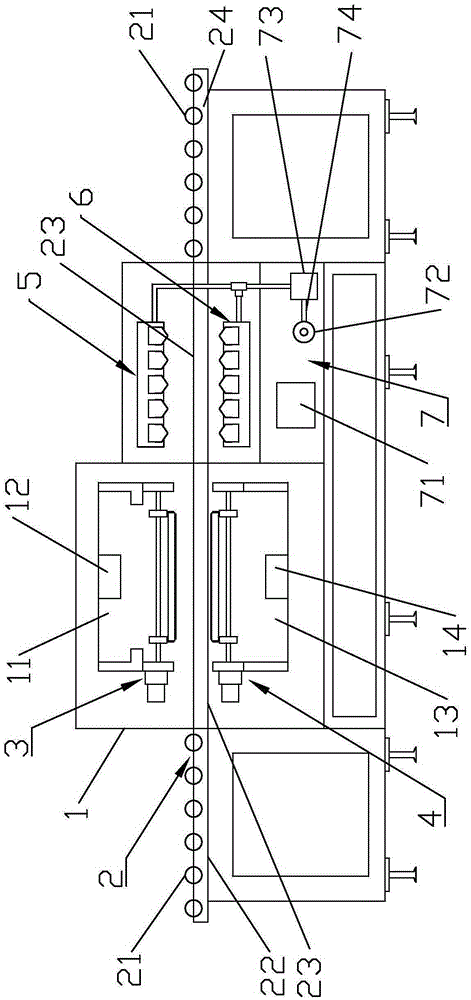

[0034] Such as Figure 1 to Figure 12 , a drying device for a glass washing machine, comprising a drying body 1, a wiper mechanism and an air knife drying mechanism are arranged in the drying body 1, and a glass transmission mechanism 2 is arranged in the middle of the drying body 1. The glass transmission mechanism 2 includes a transmission platform and transmission rollers 21, and the transmission rollers 21 are arranged horizontally between the transmission platforms. The transfer table includes an input table 22, a middle work table 23 and an output table 24. The input table 22 is located at the left end of the dryer body 1, the middle work table 23 is located in the dryer body 1, and the output table 24 is located at the right end of the dryer body 1.

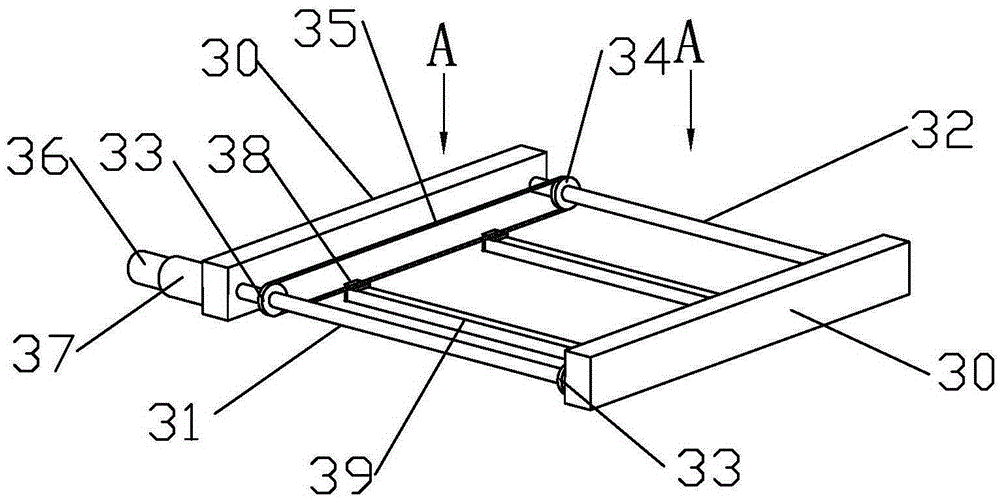

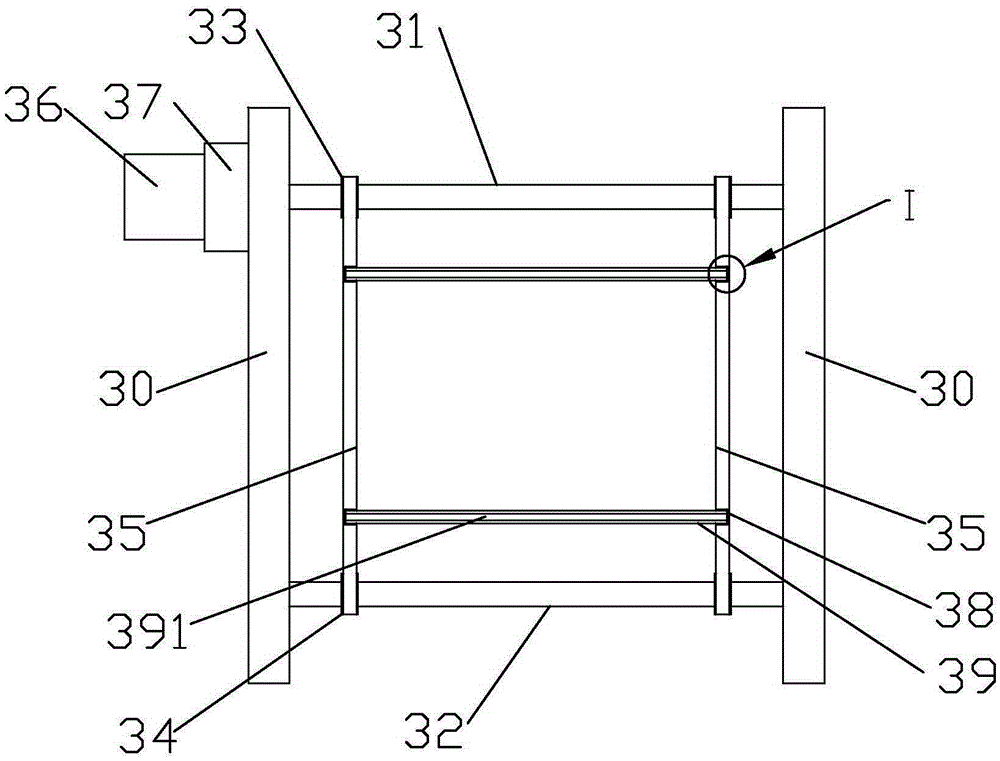

[0035] The wiper mechanism includes an upper wiper mechanism 3 and a lower wiper mechanism 4 , the upper wiper mechanism 3 is located above the transmission roller 21 , and the lower wiper mechanism 4 is located below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com