Inductance measuring apparatus for exhaust area of director guider blade

A technology for measuring exhaust area and inductance, applied in the field of aero-engines, can solve the problems of long measurement time and production cycle, unfavorable production and processing, cumbersome use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

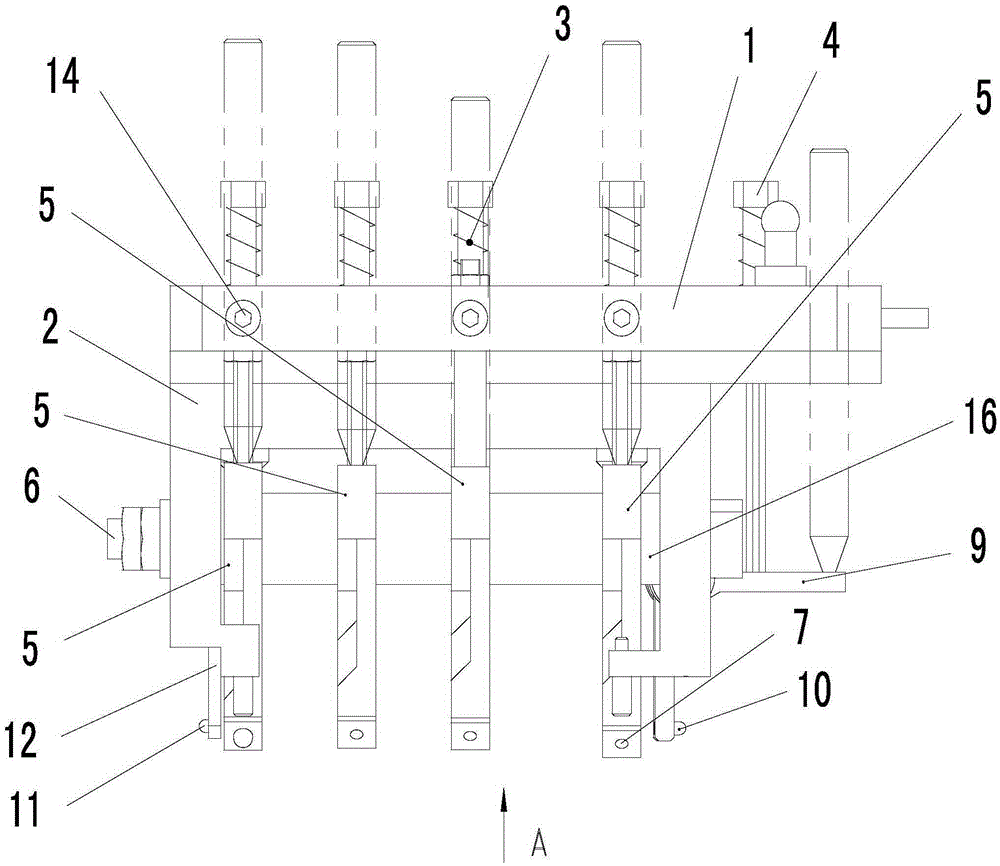

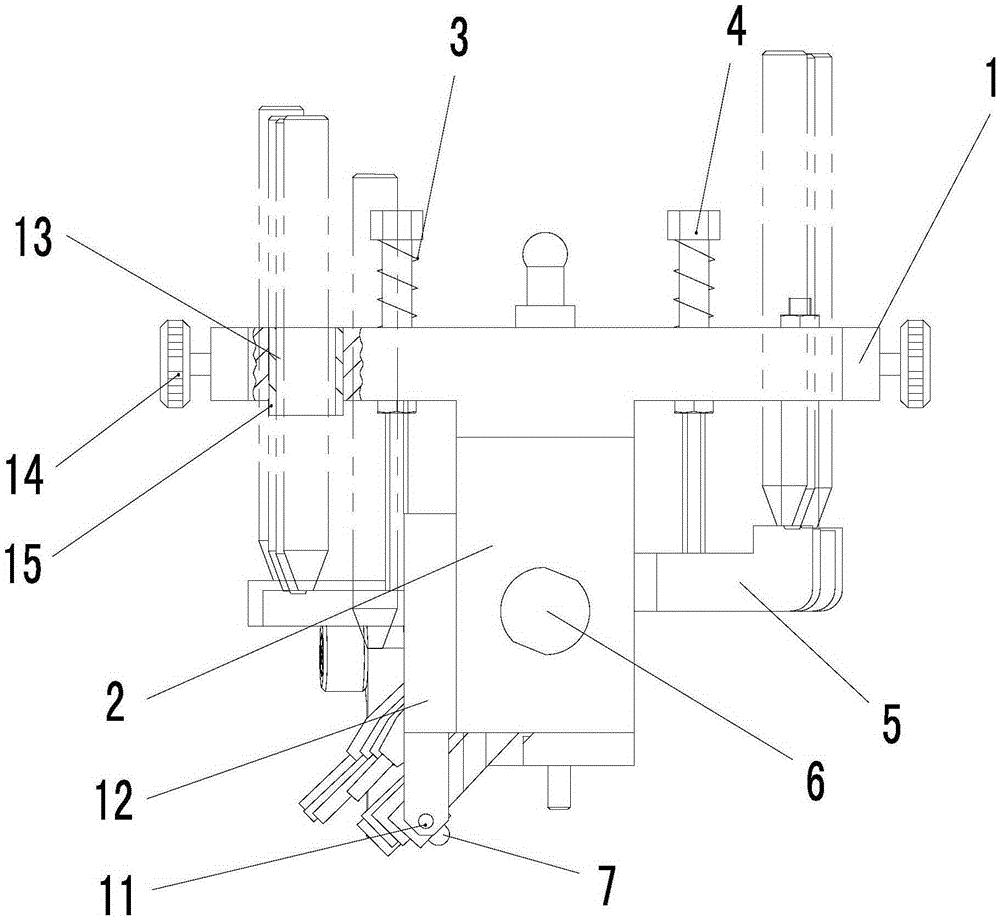

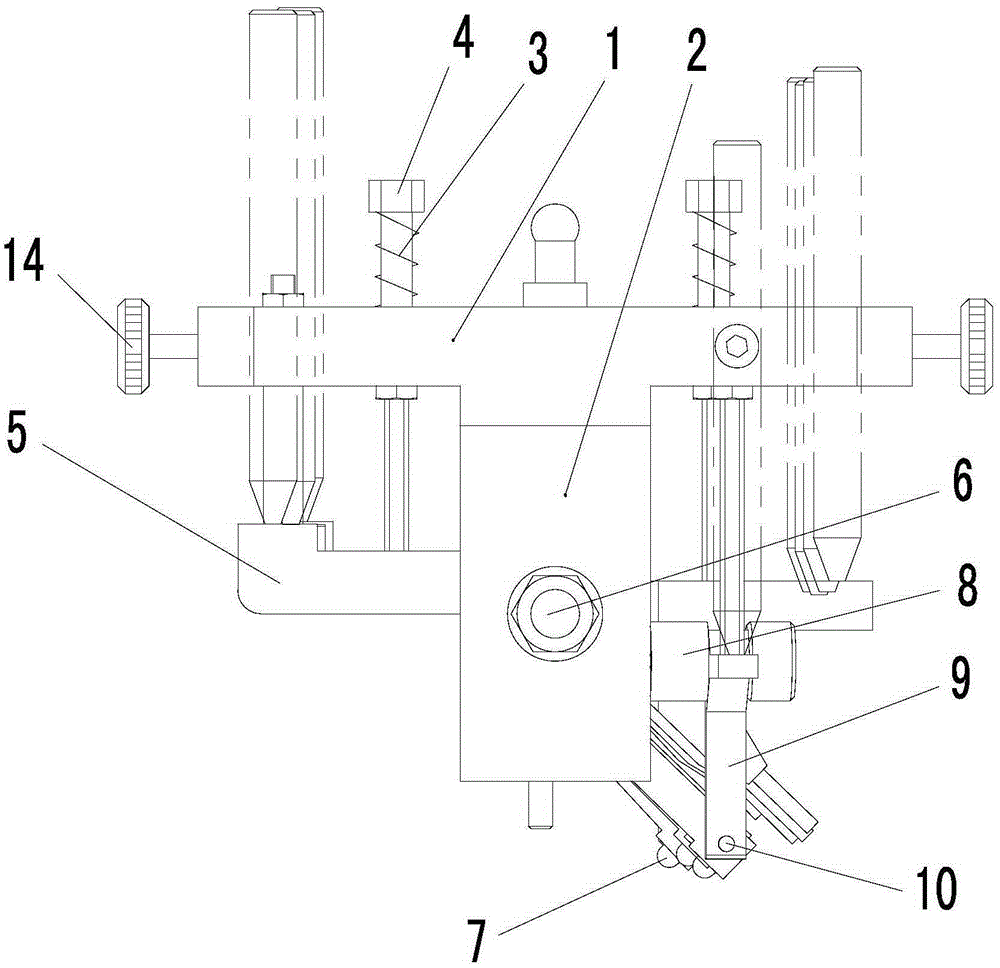

[0016] like Figure 1 to Figure 4 As shown, a guide vane exhaust area inductance measurement device includes a bracket 2, a bottom plate 1 is arranged on the upper part of the bracket 2, and a number of cross-section measuring levers 5 are arranged below the bottom plate 1; each section is correspondingly provided with two There are four cross-section measuring levers 5, in this embodiment, there are four cross-sections, so eight cross-section measuring levers 5 are correspondingly provided. The middle part of the section measuring lever 5 is arranged on the bracket 2 through the mandrel 6, and the section measuring lever 5 can rotate around the mandrel 6; , after the lower end of the limit screw 4 passes through the through hole, it is threadedly connected to the part between the upper end of the section measuring lever 5 and the mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com