Alignment method for photolithography process

A lithography process and pre-alignment technology, applied in the field of lithography process, can solve the problems of inability to complete the lithography process, penetration, and alignment failure, etc., and achieve the effect of solving strong light absorption and exposure alignment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

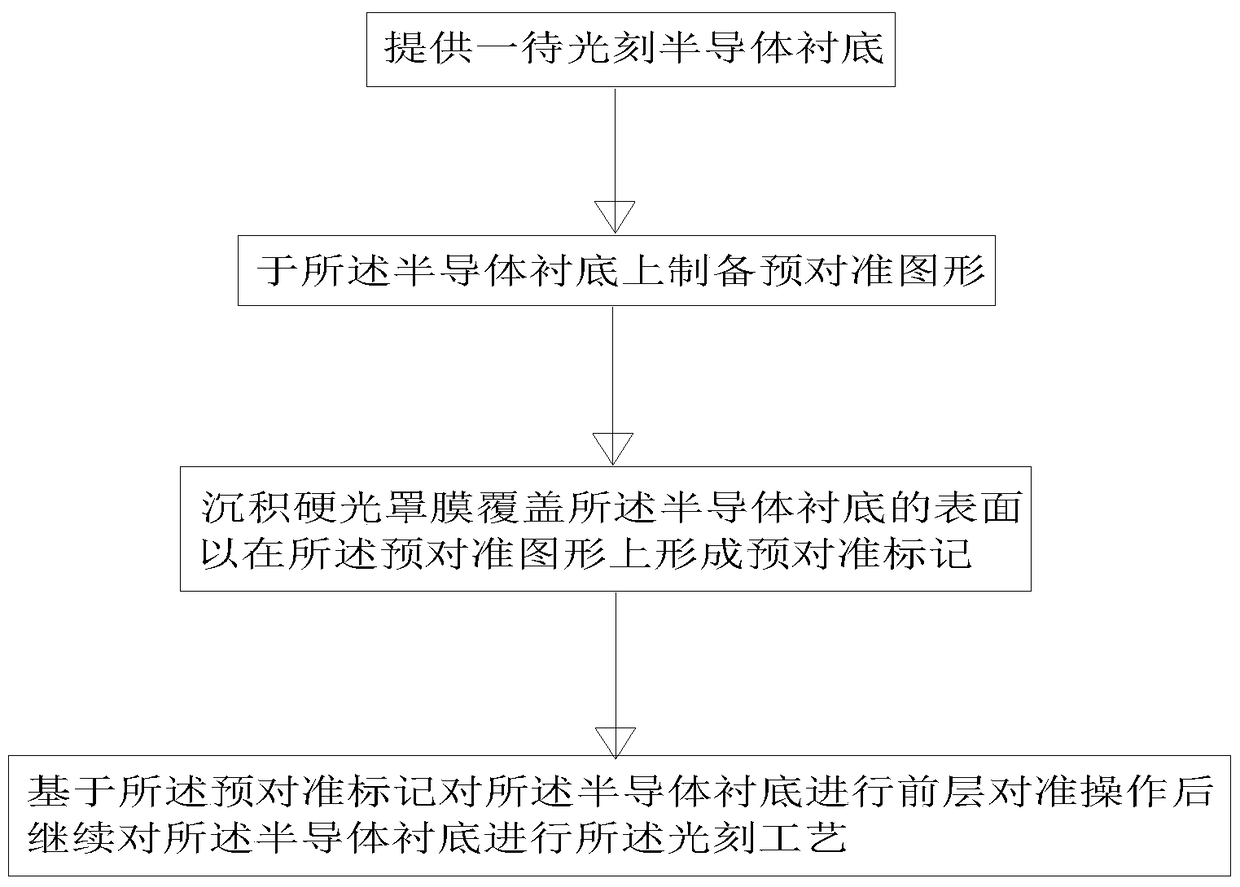

[0020] Such as figure 1 As shown, a kind of lithography process alignment method of the present invention mainly comprises the following steps: provide a semiconductor substrate to be photoetched and prepare pre-alignment pattern on this semiconductor substrate; Deposit hard mask film (preferably Kodiak film) to cover the surface of the semiconductor substrate to form a pre-alignment mark on the pre-alignment pattern; then, after performing the front layer alignment operation on the semiconductor substrate based on the pre-alignment mark, continue the semiconductor substrate performing the photolithography process; wherein, the hard mask film has a light absorption property.

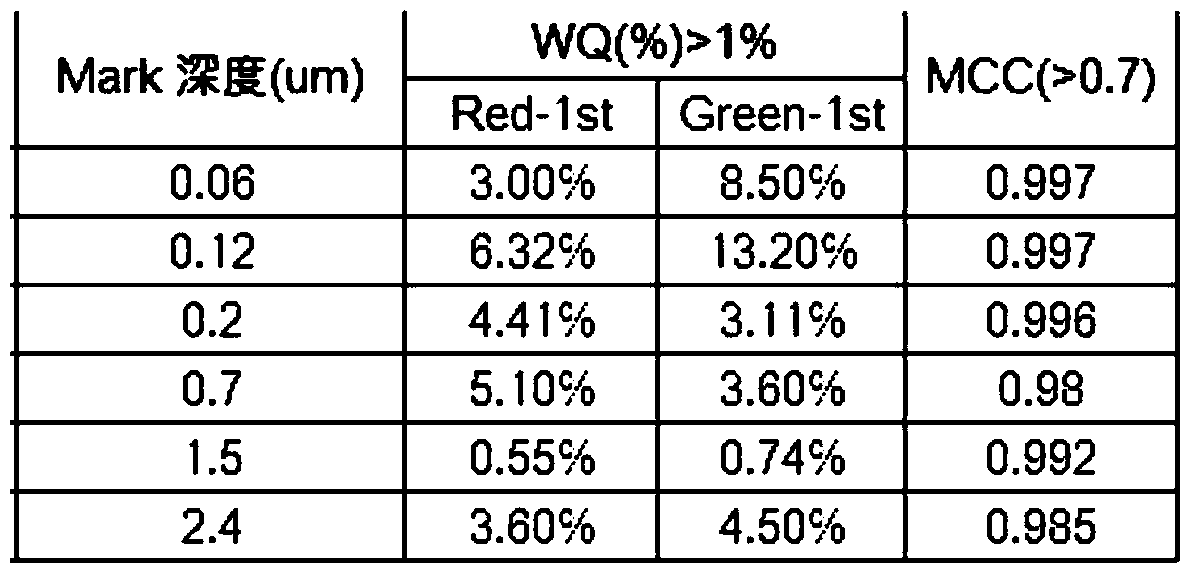

[0021] As a preferred embodiment, the above-mentioned pre-alignment pattern includes several strip parallel grooves, the depth of which is less than 120nm.

[0022] As a preferred embodiment, when the front-layer alignment operation is performed, the alignment light utilizes the undulating topography fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com