Special-purpose controller of electronic press, and control method

A control method and technology of press machine, applied in general control system, electrical program control, program control and other directions, can solve the problems of high price, increase enterprise cost, process adaptability, poor flexibility, etc., and achieve various judgment methods and equipment cost. Low, competitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below through embodiments in conjunction with the accompanying drawings.

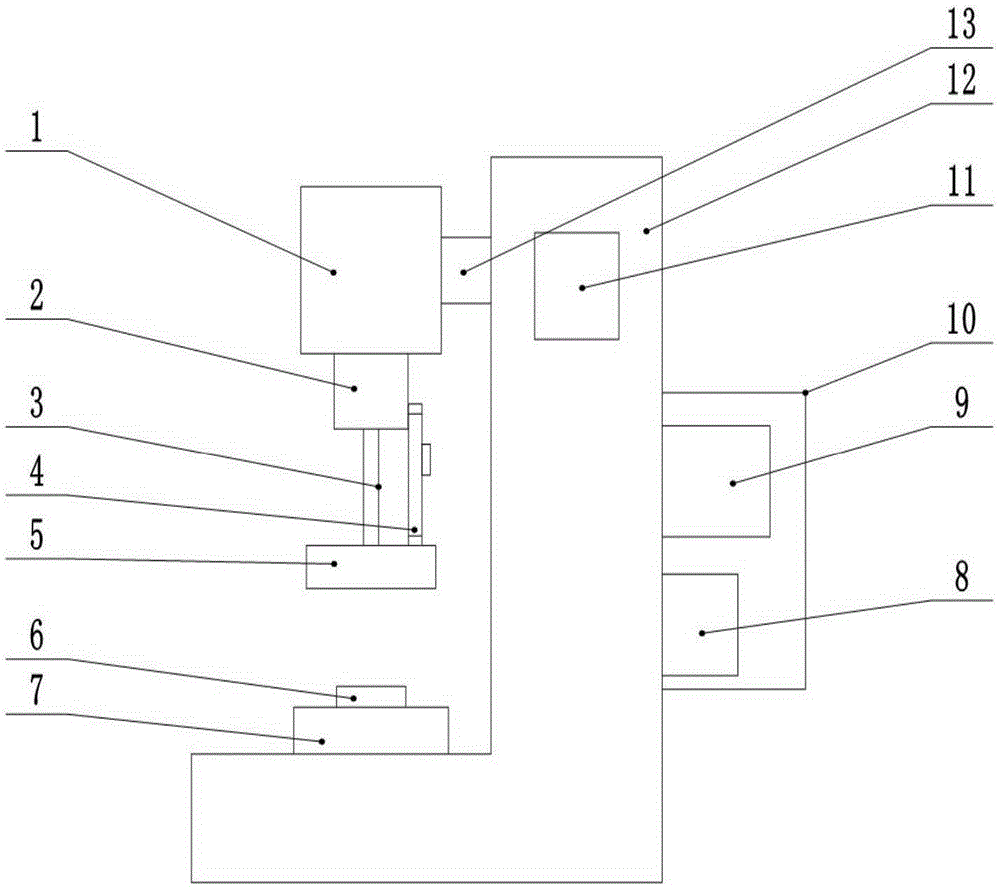

[0029] figure 1 As shown, the servo motor 1, the reducer 2, the expansion rod 3 and the pressure head 5 constitute a press-fit power mechanism; the servo motor 1 is installed on the frame 12 through the fixing seat 13; the special controller 8 and the servo driver 9 are installed together on the motor In the control box 10 (the electric control box is an iron box in the present invention), it is connected with the servo motor 1, the displacement sensor 4, the pressure sensor 7, the touch screen 11, etc. through a dedicated interface.

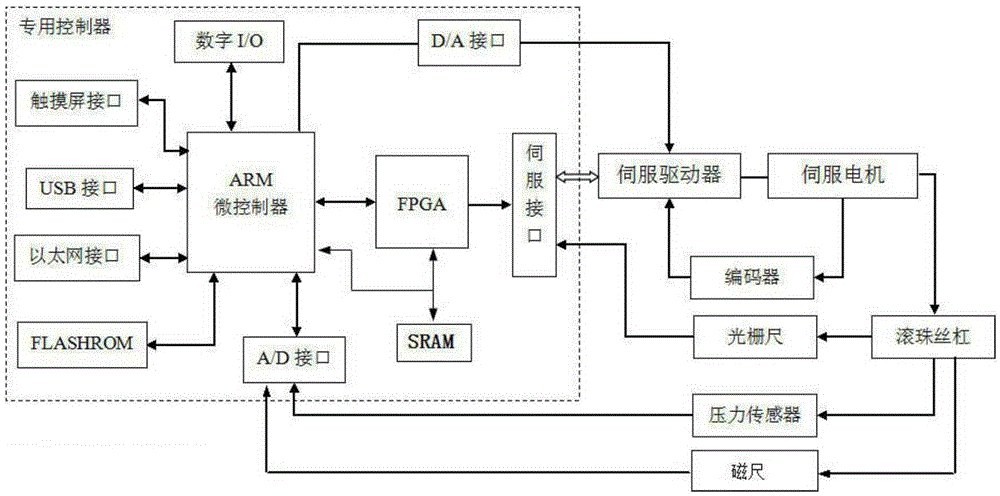

[0030] As preferably, described displacement sensor 4 can be grating ruler, also can adopt magnetic ruler, and grating ruler is a digital sensor, needs to pass to FPGA to decode through interface, and magnetic ruler is an analog quantity, needs to pass A / D channel input , specifically sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com