Final subdivision method in loading instrument of bulk carrier

A loading instrument and bulk carrier technology, applied in the direction of genetic models, etc., can solve the problems of small adjustment range and inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

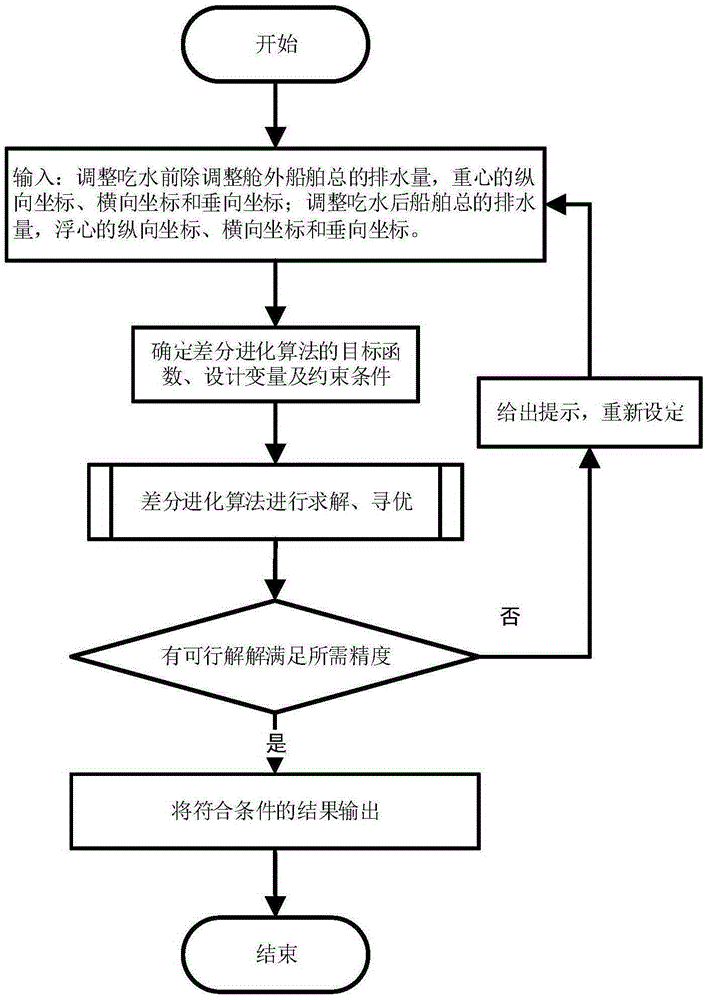

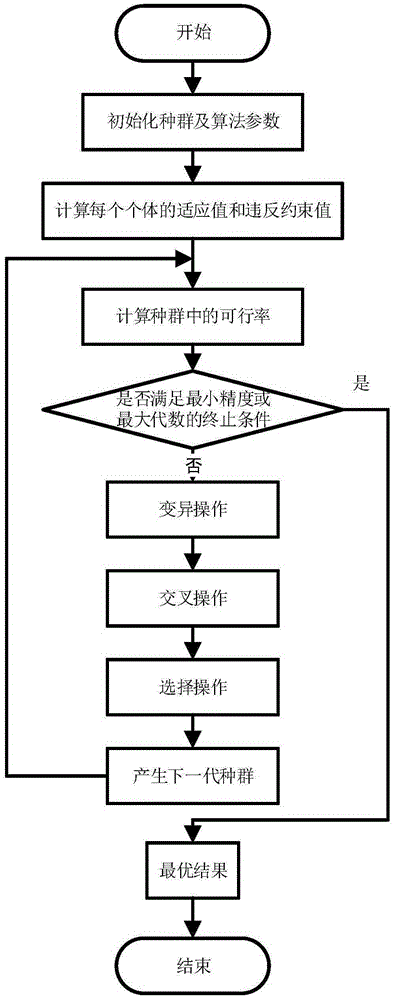

[0155] The present invention will be further described below in conjunction with the accompanying drawings. A flow chart of the final subdivision method in the bulk carrier loading instrument is as follows Figure 2-3 As shown, the value of NP in step C11 is 50; the value of δ in step C14 is 0.01.

[0156] The following takes the 250,000-ton ore carrier "SHANDONGRENHE" as an example, and selects 1 cabin and 9 cabins for the final subdivision calculation. The main dimension of the 250,000-ton ore carrier "SHANDONGRENHE": the length between vertical lines L PP =319.5m, molded width B=57m, molded depth D=25m, draft T=18m. There are 9 cargo holds in the whole ship, starting from the bow, there are 1 cabin, 2 cabins... 9 cabins.

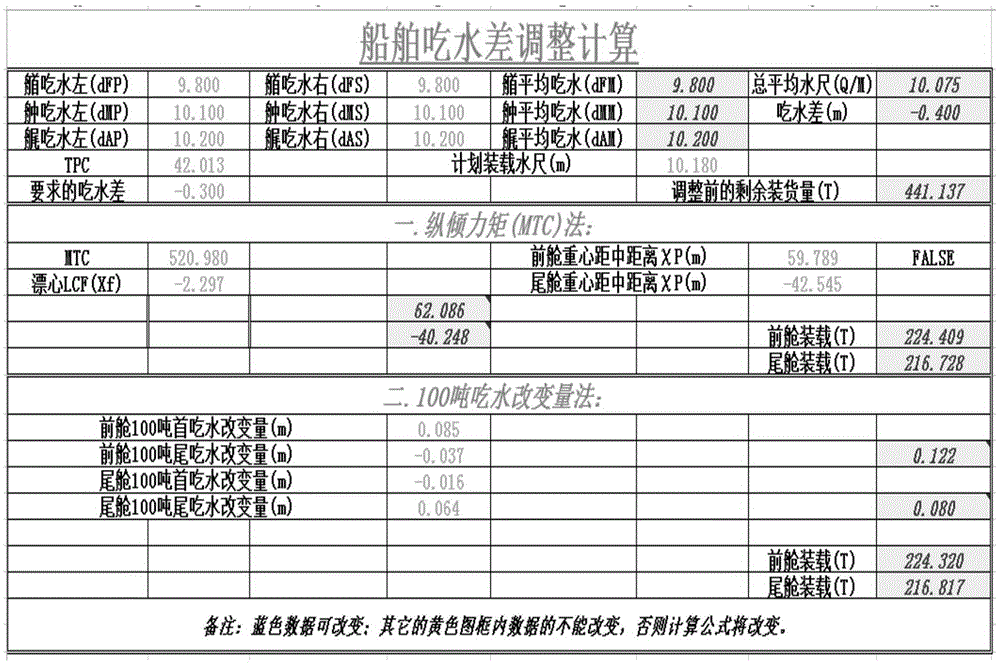

[0157] Loading condition 1: The average draft change ΔT=1.1m is relatively large, as shown in Table 1-4

[0158] Using the traditional method to calculate the cargo volume of cabin 1 and cabin 9 is 8032.734t and 7393.818t respectively, input this resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com