Production site data collection method

A collection method and on-site data technology, applied in data processing applications, electromagnetic radiation induction, instruments, etc., can solve the problem of incomplete collection of information and achieve the effect of improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

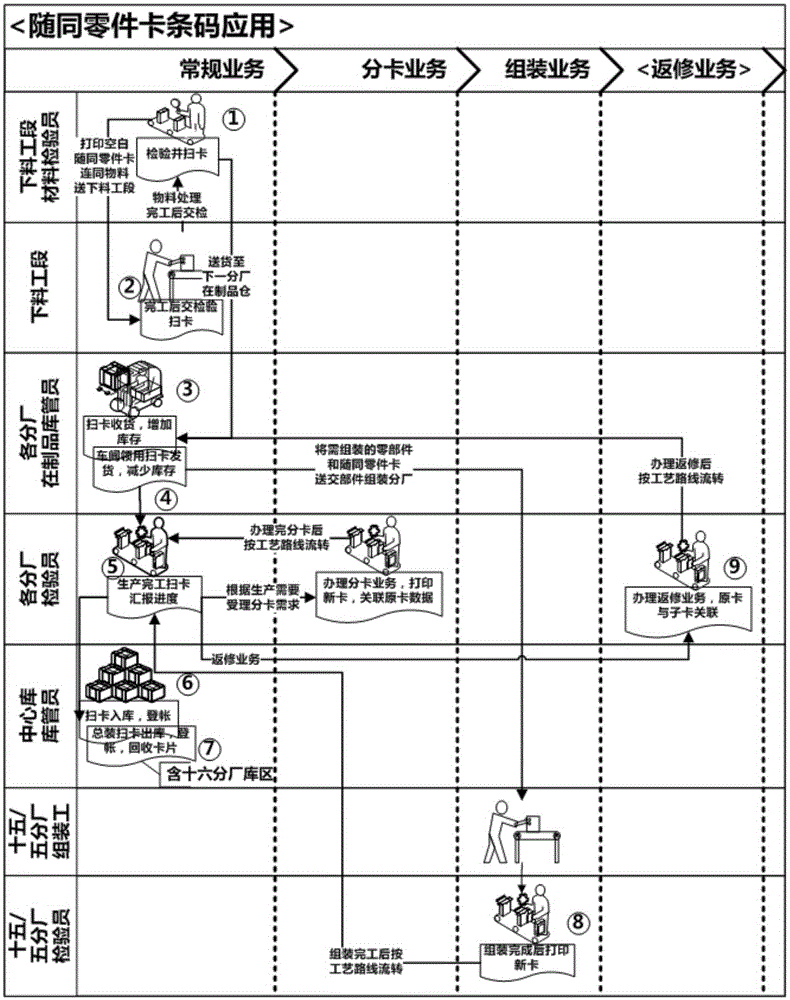

[0015] Such as figure 2 Shown, the production site data acquisition method that the present invention adopts comprises the following steps:

[0016] S1. First, establish the BOM table (product database) of each product in the ERP (Enterprise Resource Planning) system. When each batch of workpieces is put into production, the ERP system automatically assigns a unique QR code to each part number, and the QR code records the data. The product name of the part number, the name of the part number, the production and processing route and other information;

[0017] S2. Then the material inspector in the unloading section prints out the two-dimensional code label from the ERP system, and the material inspector in the unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com