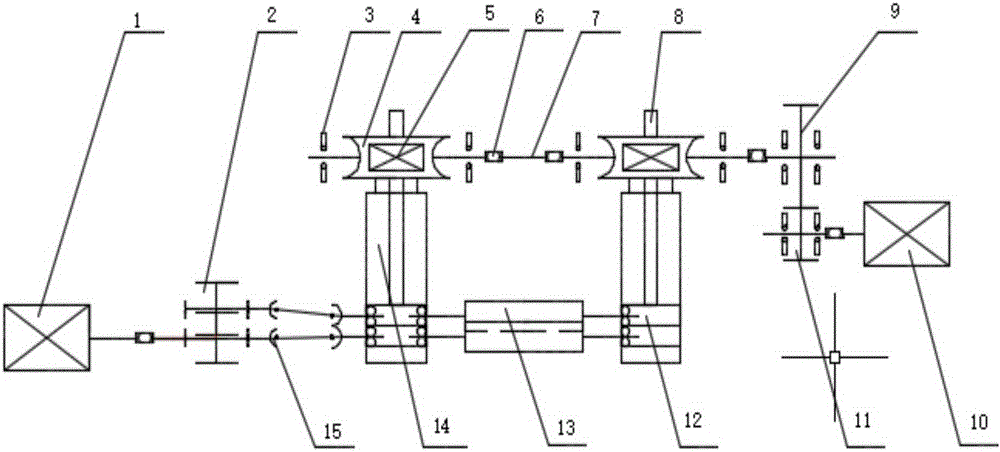

Demonstration model of roller straightening machine

A technology of straightening machine and model, applied in teaching models, educational appliances, instruments, etc., can solve the problem of not finding the teaching model of the roller straightening machine, and achieve light weight, good strength and rigidity, and reduce the space occupied. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Such as figure 1 As shown, a teaching model of a roller straightening machine is composed of a main transmission system and a pressing system, wherein the main transmission system is composed of a main motor 1, a main transmission distribution gear 2, a universal joint shaft 15 and a straightening roller 13 , the main motor 1 adopts the xd-2d06-24 type DC geared motor, the power is 15W, the speed is 10rpm, bidirectional rotation, the main transmission distribution gear 2 is five, the universal joint shaft 15 is five, and the correction roller 13 is five , the main motor 1 is connected with a gear in the distribution gear 2, through the meshing of the remaining four gears, it drives five universal joint shafts 15, and then drives five correction rollers 13 to rotate, and each gear is installed on the rotating shaft There are bearings. The main motor 1 drives the main transmission distribution gear 2, and the main transmission distribution gear 2 drives the universal joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com