Vertical-roller rolling mill teaching model

A vertical rolling mill and teaching technology, used in teaching models, metal rolling stands, metal rolling mill stands, etc., can solve the problem that theory and practice cannot be organically combined, and vertical rolling mills cannot be displayed to students and classroom teaching. Content abstraction and other issues to achieve the effect of light weight, good strength and stiffness, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

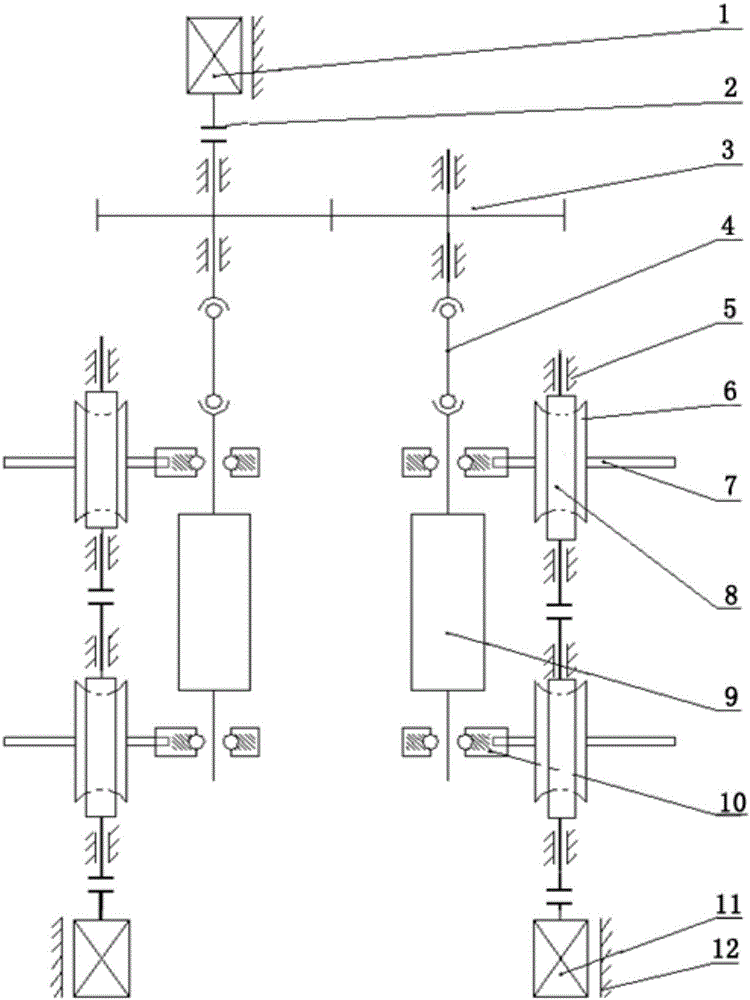

[0023] see figure 1 , A teaching model of vertical rolling mill, including main motor 1, coupling 2, distribution gear 3, universal joint 4, bearing 5, worm gear 6, side pressure screw 7, worm 8, vertical roller 9, bearing seat 10. The side pressure motor 11, the distribution gear 3 is composed of two gears that mesh with each other. The main motor 1 is connected with a gear through a coupling 2, and the two gears meshing with each other are connected to two vertical shafts through a universal joint 4 respectively. The rollers 9 are connected; the main motor 1 uniformly transmits torque and movement to the two vertical rollers 9 through the coupling 2, the distributing gear 3 and the universal joint shaft 4, so as to realize the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com