A waterproof capacitor installation device

An installation device, waterproof technology, applied in the direction of capacitors, electrical components, etc., can solve the problems of fragile studs, unable to prevent drying of terminals, capacitors falling off, etc., to achieve the effect of stable fixation and prevention of short circuit burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

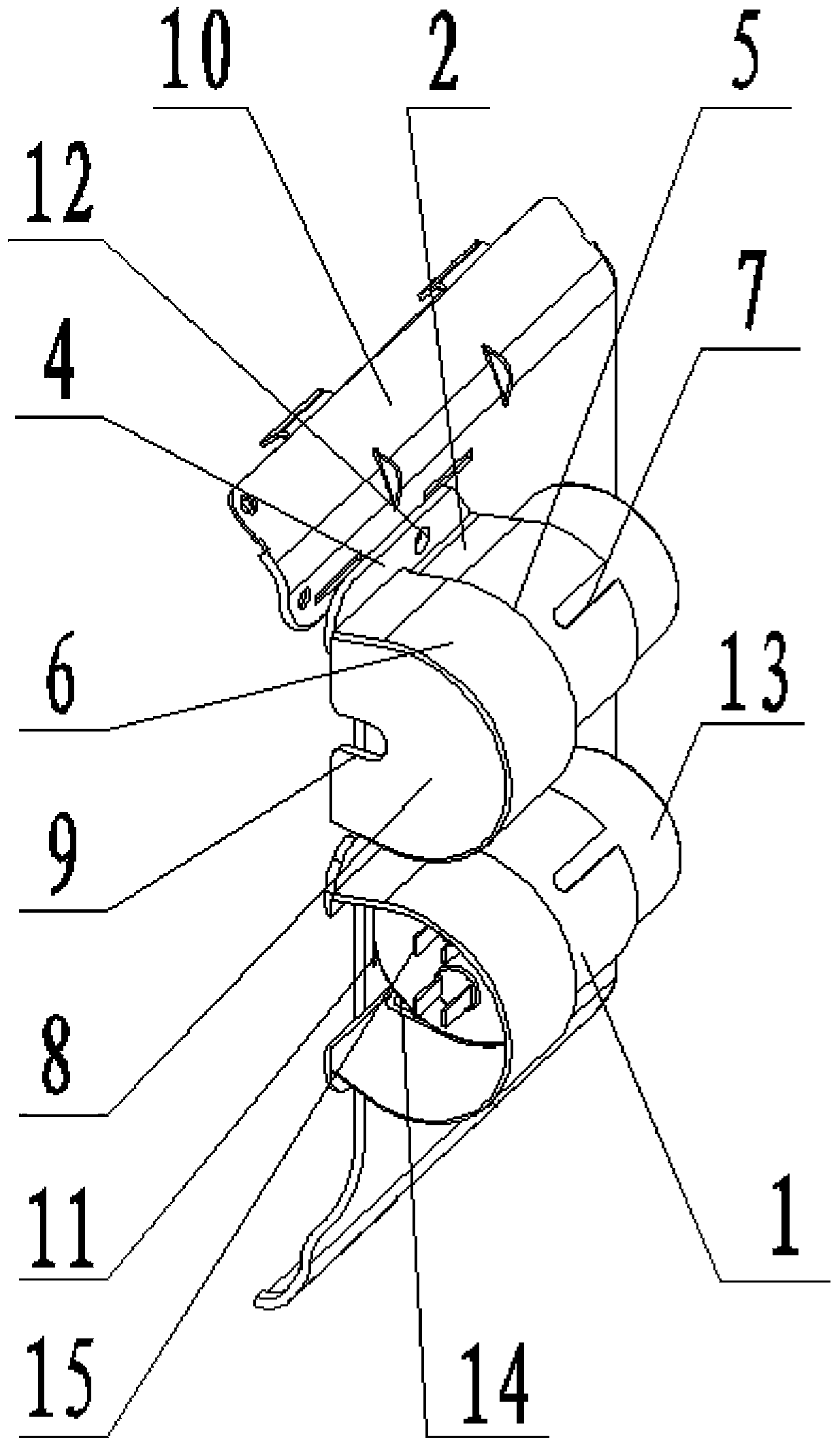

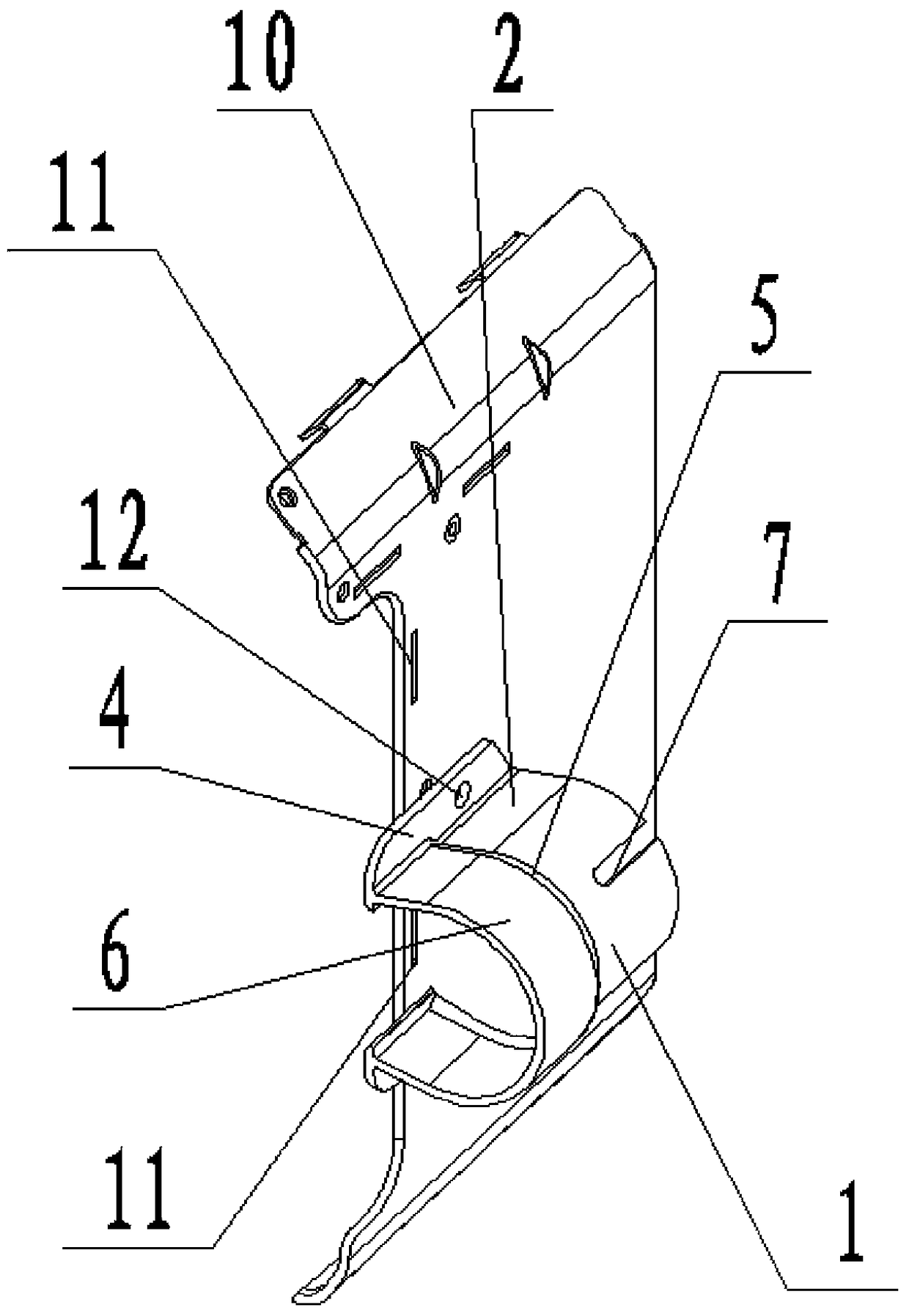

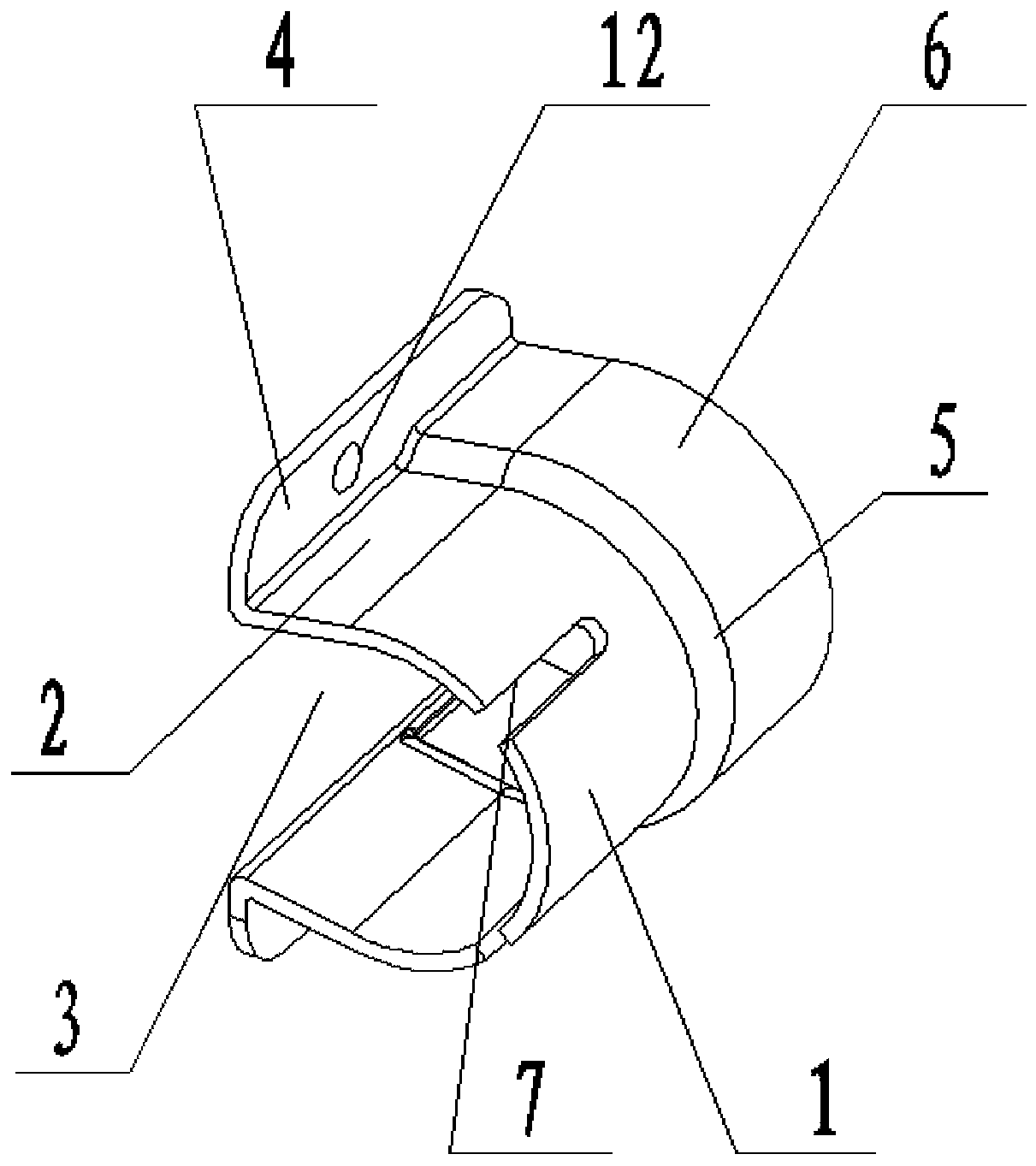

[0044] Such as figure 1 , figure 2 As shown, the present invention includes an elastic semi-cylindrical arc-shaped clamping surface 1 and clamping surfaces 2 provided on both sides of the circular arc-shaped clamping surface 1 in the axial direction. An assembly opening 3 is provided between the clamping surfaces 2, and an assembly edge 4 is provided on the sides of the two clamping surfaces 2 away from the arc-shaped clamping surface 1. The arc-shaped clamping surface 1 The middle part of the inner surface of the capacitor is provided with a ring-shaped capacitor end cover protrusion limiting portion 5, the ring-shaped capacitor end cover protrusion limiting portion 5 is coaxial with the arc-shaped clamping surface 1, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com