Front wiper motor

A technology of wiper and motor housing, applied in the field of wiper motor, can solve the problems of complicated assembly, uncontrollable fillet radius, poor sealing between metal gland and plastic part, etc., so as to save assembly time and reduce manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation, features and functions of a front wiper motor proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

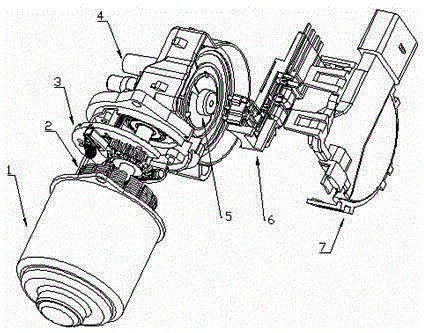

[0026] Such as figure 1 Shown is a schematic diagram of the assembly of the wiper motor, including a motor housing 1 , an armature 2 , a brush holder ring 3 , a reducer housing 4 , a worm gear component 5 , an integrated block 6 , and a gland component 7 .

[0027] Viewed from the outside, the motor housing 1 and the reducer housing 4 are connected by screws, the gland part 7 and the reducer housing 4 are connected by buckles, the motor housing 1, the reducer housing 4, and the gland part 7 The three form the shape of the wiper motor. After the motor is energized, the internal armature 2 rotates at a high speed, and the teeth of the armature 2 mesh with the teeth of the worm gear part 5 to drive the worm gear part 5 to rotate, and the worm gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com