Wind-power vacuum alkali reduction apparatus for reclamation of saline and alkaline land and use method of apparatus

A technology for reducing alkali and saline-alkali land by vacuum, applied in the application, agricultural machinery and equipment, climate change adaptation and other directions, can solve the problems of unachievable alkali discharge, poor improvement effect, unattainable air permeability, etc., to reduce operating costs and structural design. Reasonable and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

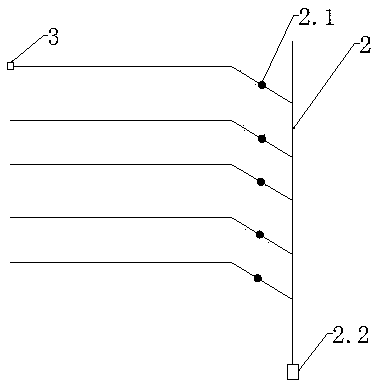

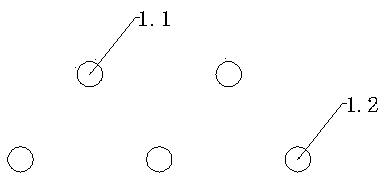

[0014] The surface soil of the saline-alkali land is leveled and excavated with buried pipe grooves, in which the alkali discharge pipeline is arranged in the buried pipe groove, and the alkali discharge pipeline includes the upper alkali discharge python pipe and the lower alkali discharge python pipe, and the upper alkali discharge pipe is set The vertical direction between the adjacent pipelines of the lower alkali discharge pipes is staggered. One end of the upper alkali discharge pipe and the lower alkali discharge pipe is connected to the vacuum pipe, and the end of the vacuum pipe is connected to a vacuum pump, and the vacuum pump is connected to the power unit. When carrying out alkali discharge work, fresh water is poured on the surface of the ground, and the underground alkali discharge pipes are connected with vacuum pipes, the vacuum pump is turned on, and the alkali discharge pipes are pumped through the vacuum pipes to form a negative pressure. With the positive p...

Embodiment 2

[0016] There is an observation well connected to the ground at the other end of the alkali discharge pipe, and the working conditions of the alkali discharge pipe can be observed from the ground. Specifically, it can be observed on the ground whether the alkali discharge pipe is blocked and the water filtration speed. And at the end of the other end of the alkali discharge pipe, a quick-fit joint can be installed to clean the alkali discharge pipe. The ends are connected, and the quick-fit joint is connected to the high-pressure pump through the pipeline. Under the operation of the high-pressure pump, the alkali discharge pipe is subjected to high-pressure flushing and membrane recoil, and the blockage in the alkali discharge pipe is washed away, ensuring The smoothness of the pipeline and the water filtration capacity of the filter membrane, because the quick-fit joint is detachable, it can be installed when the alkali discharge pipe needs to be cleaned, and removed when it is...

Embodiment 3

[0018] In the early stage of pipe distribution, the present invention firstly leveled and plowed the land, and loosened the soil with a ripper. It is easier to discharge alkali during pressure pouring.

[0019] Through the double function of negative pressure and positive pressure, the present invention achieves the improved effect without a large amount of fresh water resources, and does not need a long time of alkali discharge process, and the alkali discharge cycle is at least shorter than the traditional method of alkali discharge After one year, the most obvious effect will be achieved in that year, and the best effect will be achieved in the second year. The alkali discharge efficiency is twice that of the traditional alkali discharge method, and in areas with strong wind and more solar resources, the use of wind energy and solar energy can directly As a power source, the operating cost is reduced, and the effect of green power changing to alkali is achieved. It is very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com